Rigaku makes X-ray diffraction (XRD) and X-ray fluorescence (XRF) instrumentation for material characterization and element analysis at every stage of the exploration, production and distribution process, such as for sulfur analysis and other elements in crude oil and fuels. Rigaku instruments comply with the relevant measurement protocols, including ASTM D2622, D7220, D4294, and IP 532, as well as EN ISO 8754 & 20847. The Rigaku NEX XT process analyzer is used for on-line measurement of sulfur for pipeline, blending and upgrading, as well as bunker fuel blending for MARPOL compliance and additive packages for lubricating oils.

Application Notes

The following application notes are relevant to this industryEDXRF

WDXRF

XRD

X-ray topography (XRT)

Process

WDXRF, XRF

Rigaku recommends the following systems:

WDXRF

Benchtop tube below sequential WDXRF spectrometer analyzes O through U in solids, liquids and powders

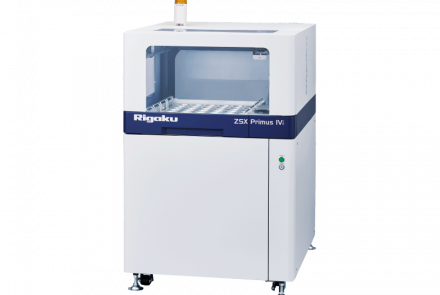

High power, tube above, sequential WDXRF spectrometer with new ZSX Guidance expert system software

High-power, tube-below, sequential WDXRF spectrometer with new ZSX Guidance expert system software

Affordable, high-end, tube-above Industrial WDXRF for the analysis of solid samples

XRD

New 6th-generation general purpose benchtop XRD system for phase i.d and phase quantification

EDXRF

Low-cost EDXRF elemental analyzer measures Na to U in solids, liquids, powders and thin-films

Performance EDXRF elemental analyzer measures Na to U in solids, liquids, powders and thin-films

High-performance, Cartesian-geometry EDXRF elemental analyzers for measuringes Na to U in solids, liquids, powders and thin films