NEX CG II Series

Next-Generation Cartesian Geometry Energy Dispersive X‑ray Fluorescence Spectrometers

Enhanced elemental analysis for industrial quality control to advanced research applications

NEX CG II Series are powerful second-generation energy dispersive X-ray fluorescence (EDXRF) spectrometers that deliver rapid qualitative and quantitative determination of major and minor atomic elements in a wide variety of sample types—from oils and liquids to solids, metals, polymers, powders, pastes, coatings, and thin films.

NEX CG II Series Overview

The Rigaku NEX CG II Series are multi-element, multi-purpose analyzers, ideal for measuring ultra-low and trace element concentrations into the percent levels. These analyzers serve many industries and are especially well-suited for semi-quantitative determination of elemental content in complete unknowns. Applications range from industrial and in-plant quality assurance to research and development. They are easy to use for non-technical operators yet powerful enough for expert use in commercial labs and R&D facilities. Users can achieve the lowest limits of detection and easily manage complex applications. NEX CG II Series are ideal for testing agricultural soils and plant materials, analyzing finished animal feeds, measuring waste oils, environmental monitoring, pharmaceuticals, cosmetics, and many others.

Available models are NEX CG II for excellent spectral resolution for trace peaks or NEX CG II+ for more demanding applications requiring a higher-powered system.

Cartesian geometry and polarization for trace-level sensitivity

NEX CG II Series build on NEX CG’s legacy of using Cartesian Geometry and secondary targets for trace-level sensitivity. NEX CG II Series feature a unique and improved close-coupled Cartesian Geometry optical kernel that dramatically increases signal-to-noise ratio and delivers enhanced elemental analysis.

Unlike conventional EDXRF spectrometers, NEX CG II Series are indirect excitation systems using secondary targets rather than tube filters. Monochromatic and polarized excitation from secondary targets vastly improves detection limits for elements in highly scattering matrices like water, hydrocarbons, and biological materials. Secondary target excitation in full 90° Cartesian Geometry eliminates background noise. As a result, NEX CG II Series bring a new level of analytical sensitivity to XRF technology. Users can measure ultra-low and trace element concentrations, even in challenging sample types.

NEX CG II Series achieve superior analytical power with either a 50 kV 50 W (NEX CG II) or 65 kV 100 W (NEX CG II+) end-window palladium-anode X-ray tube, five secondary targets covering the complete elemental range sodium through uranium (Na – U), and a high-throughput large-area silicon drift detector (SDD). This unique optical kernel, combined with Rigaku’s advanced RPF-SQX Fundamental Parameters software, delivers the most sensitive EDXRF measurements in the industry.

Easy instrument control with advanced qualitative and quantitative analytical software

NEX CG II Series are easy to use with QuantEZ, a powerful PC-based software providing intuitive instrument control with simple menu navigation and a customizable EZ Analysis interface. Users can maximize their time and productivity with simplified routine operations and create their own methods using a simple flow bar wizard. In addition, various software options are available to meet user needs, including SureDI, supporting compliance with 21 CFR Part 11.

Advanced qualitative and quantitative analysis is powered by Rigaku’s RPF-SQX Fundamental Parameters (FP) software, featuring Rigaku Profile Fitting (RPF) technology and Scattering FP. This robust integrated software allows semi-quantitative analysis of almost all sample types without standards—and rigorous quantitative analysis with standards. Rigaku’s Scattering FP method automatically estimates the concentration of unmeasurable low atomic number elements (H to F) and provides appropriate corrections.

Calibration standards can be expensive and difficult to obtain for many applications. With RPF-SQX, the number of required standards is greatly reduced, significantly lowering the cost of ownership and reducing workload requirements for running routine analyses.

NEX CG II Series Features

NEX CG II Series Videos

NEX CG II Series Specifications

| Technique | Indirect excitation energy dispersive X-ray fluorescence (EDXRF) | |

|---|---|---|

| Benefit | Excel in complex applications with trace elements and variable base matrices; analyze solids, liquids, powders, coatings, and thin films | |

| Technology | 3D Cartesian geometry energy dispersive XRF (EDXRF) using a large-area high-throughput silicon drift detector (SDD) | |

| Attributes | High-power X-ray tube (50 kV 50 W or 65 kV 100 W), large-area high-throughput SDD, analyze Na to U | |

| Software | QuantEZ for control of spectrometer functions and data analysis | |

| Options | Vacuum, helium purge, automatic sample changers, sample spinner tray, external PC with Microsoft Windows operating system, UPS, RPF-SQX Fundamental Parameters with Rigaku Scattering FP, SureDI support for 21 CFR Part 11 compliance, other software features | |

| Dimensions | 46.3 (W) x 49.2 (D) x 38.2 (H) cm | |

| Mass | Approx. 65 kg (NEX CG II); approx. 68 kg (NEX CG II+) | |

| Power requirements | 1Ø, 100 – 240 V, 3.8 – 1.6 A (50/60 Hz) or 100 – 240 V, 5.2 – 2.6 A (50/60 Hz) | |

| Warranty | 2 years | |

NEX CG II Series Options

The following accessories are available for this product:

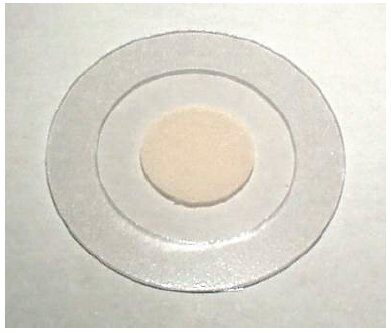

Ultra Carry

Ultra Carry is a novel disposable (single-use) sample retainer for XRF analysis used to preconcentrate a liquid sample into a uniform sample carrier optimized for the suppression of background noise.

NEX CG II Series Application Notes

The following application notes are relevant to this product

-

EDXRF3226 - NEX CG II - Analysis of Nutrients in Silage

-

EDXRF3209 - Analysis of Coal

-

EDXRF3198 - Animal Feed Analysis

-

EDXRF3144 - Analysis of Lube Oils by ASTM D7751

-

EDXRF3142 - Analysis of Coal Fly Ash

-

EDXRF3137 - Ultra Carry Detection Limits

-

EDXRF3133 - Analysis of Air Filters - U.S. EPA Sensitivity

-

EDXRF3134 - Analysis of Rare Earth Elements in Clay

-

EDXRF3122 - Ultra Carry Detection Limits

-

EDXRF3001 - Pb in Gasoline by ASTM D5059 Part C and A

-

EDXRF2096 - Organic Chlorides in Crude by ASTM D4929 Part C

-

EDXRF1994 - Material Identification

-

EDXRF2099 - Manganese in Gasoline by ASTM D5059 Part D

-

EDXRF3000 - EPA Tier 3 Gasoline

-

EDXRF2095 - Analysis of ULSD

-

EDXRF3051 - Analysis of Cement and ASTM C114 Qualification

-

EDXRF3064 - Analysis of Air Filters - U.S. EPA Sensitivity

NEX CG II Series Resources

Rigaku Journal articles

| Read the Article |

Legacy NEX CG application notes

The following application notes are first-generation NEX CG legacy documents. They reflect the minimum performance achievable using NEX CG II Series spectrometers.

| EDXRF1023 - Analysis of PVC Resins | Read Application Note |

| EDXRF1033 - Chlorine and RoHS Elements in Polyethylene | Read Application Note |

| EDXRF1054 - SiO₂, AlSi, Ti, TiN, Pt, AlCu, and BPSG on Silicon | Read Application Note |

| EDXRF1061 - Analysis of Heavy Metals in Aerosols on Air Filters | Read Application Note |

| EDXRF1108 - Analysis of Limestone | Read Application Note |

| EDXRF1241 - Analysis of Gemstones | Read Application Note |

| EDXRF1385 - Agricultural Soils and Plant Materials | Read Application Note |

| EDXRF1495 - Analysis of Lead (Pb) / Zinc (Zn) Ore | Read Application Note |

| EDXRF1853 - Analysis of Fiberglass | Read Application Note |

| EDXRF1884 - Alloy Powders for 3D Printing | Read Application Note |

| EDXRF1970 - Metals in Crude and Resid as per ASTM D8252 | Read Application Note |

NEX CG II Series Events

Learn more about our products at these events

-

EventDatesLocationEvent website

-

Pittcon 2026March 9 2026 - March 11 2026San Antonio, TX, USA

-

AWA Global Release Liner SummitMarch 11 2026 - March 13 2026Amsterdam, Netherlands

-

AnalyticaMarch 24 2026 - March 27 2026Munich, Germany

-

STLE Annual Meeting & ExhibitionMay 17 2026 - May 21 2026New Orleans, LA, USA

-

Labelexpo Americas 2026September 15 2026 - September 17 2026Chicago, IL

NEX CG II Series Training

Upcoming training sessions

-

TitleDatesCostLocationNotesCourse outlineRegistration form

-

EDXRF Operator Training (USA)January 19 2026 - January 20 2026Please contact info@RigakuEDXRF.comCedar Park, TexasGet hands-on training for NEX benchtop analyzers. Through direct experience, you will gain knowledge and skills in instrument calibration, method development, easy sample preparation techniques, and software operation.

-

EDXRF Operator Training (USA)March 23 2026 - March 24 2026Please contact info@RigakuEDXRF.comCedar Park, TexasGet hands-on training for NEX benchtop analyzers. Through direct experience, you will gain knowledge and skills in instrument calibration, method development, easy sample preparation techniques, and software operation.

-

EDXRF Operator Training (USA)May 4 2026 - May 5 2026Please contact info@RigakuEDXRF.comCedar Park, TexasGet hands-on training for NEX benchtop analyzers. Through direct experience, you will gain knowledge and skills in instrument calibration, method development, easy sample preparation techniques, and software operation.

-

EDXRF Operator Training (USA)July 13 2026 - July 14 2026Please contact info@RigakuEDXRF.comCedar Park, TexasGet hands-on training for NEX benchtop analyzers. Through direct experience, you will gain knowledge and skills in instrument calibration, method development, easy sample preparation techniques, and software operation.

-

EDXRF Operator Training (USA)September 14 2026 - September 15 2026Please contact info@RigakuEDXRF.comCedar Park, TexasGet hands-on training for NEX benchtop analyzers. Through direct experience, you will gain knowledge and skills in instrument calibration, method development, easy sample preparation techniques, and software operation.

-

EDXRF Operator Training (USA)November 9 2026 - November 10 2026Please contact info@RigakuEDXRF.comCedar Park, TexasGet hands-on training for NEX benchtop analyzers. Through direct experience, you will gain knowledge and skills in instrument calibration, method development, easy sample preparation techniques, and software operation.

NEX CG II Series

Testimonials

-

We're able to confidently analyze a diverse array of samples, including solids, sands, oil, and water, all with one versatile instrument.

Read the full testimonialTanhee GalindoGeoKimika -

Customer service from Rigaku has been excellent and I would highly recommend this analyzer for use especially in the petrochemical field.

Read the full testimonialChemistFortune 500 Energy Company

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.