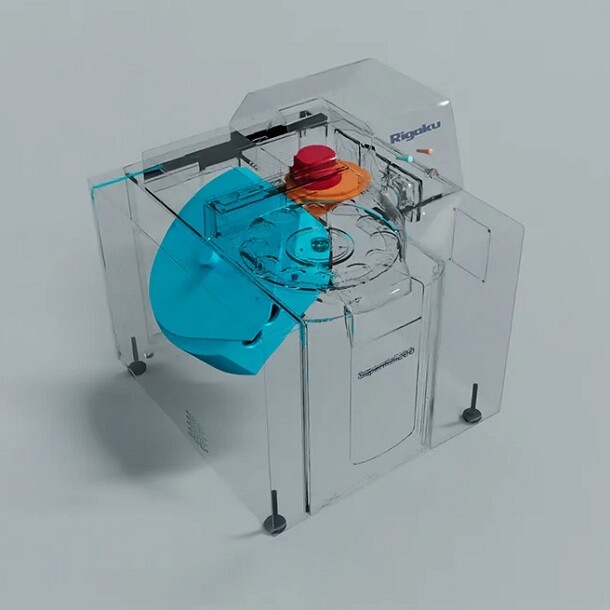

Supermini200

High-Power Benchtop Sequential WDXRF Spectrometer

Elemental analysis of solids, liquids, powders, alloys and thin films

Compared to competing XRF systems, the Rigaku Supermini200 offers superior fundamental parameters and empirical software capabilities in a high resolution instrument with a compact footprint. As a high-power benchtop sequential wavelength dispersive X-ray fluorescence (WDXRF) spectrometer, for elemental analysis of oxygen (O) through uranium (U) in almost any material, the Supermini200 uniquely delivers low cost-of-ownership (COO) with high resolution and lower limits-of-detection (LLD).

Supermini200 Overview

WDXRF performance with low costs

Not only is the Rigaku Supermini200 spectrometer an affordable choice for your XRF elemental analysis needs, the running costs are also low. P10 gas for the flow proportional detector is the only consumable. The Supermini200 does not require a source of cooling water, plumbing, or an external chiller, thereby decreasing system maintenance and lowering the overall lifetime cost of ownership of the system and yearly budgets for consumables and maintenance.

WDXRF for light element performance

Analyzing complex matrix materials with a wide range of light and heavy elements, from trace to high concentration levels, is this instrument's core competency. With its high powered (200 W) X-ray tube, Rigaku Supermini200 delivers high XRF sensitivity for light elements with superior spectral resolution for resolving line overlaps in complex matrices without the need for complicated mathematical peak deconvolution. Analyzing low concentration levels of light elements (F, Na, Mg, Ca, Si, Al, and P) is easy.

Highest resolution for difficult samples

Supermini200 WDXRF spectrometer is equipped with a three position crystal changer where LiF(200) and PET are mounted as standard crystals. RX26, Ge or RX-9 can be added optionally, with the RX9 providing higher sensitivity and resolution for P, S and Cl peaks.

Supermini200 Features

(S-PC not requiring P10 gas optionally available)

Optional: 12 sample positions (up to 44mm diameter samples)

Supermini200 Videos

Supermini200 Specifications

| Technique | Wavelength dispersive X-ray fluorescence spectroscopy (WDXRF) | |

|---|---|---|

| Benefit | Elemental analysis: O to U | |

| Technology | Sequential WDXRF | |

| Attributes | Air cooled 200 W X-ray tube, 12-position autosampler, LiF(200) and PET crystals | |

| Options | He-purge Fundamental parameters Extra RX25 or Ge crystal |

|

| Computer | External PC, MS Windows OS | |

| Dimensions | 580 (W) x 670 (H) x 680 (D) mm | |

| Mass | 100 kg | |

| Power requirements | 1Ø, 100-120V 15A or 200-240V, 10A | |

Supermini200 Options

The following accessories are available for this product:

Air/Vacuum Atmosphere Measurement (Sealing unit)

Measurement of liquids and fine powders with Supermini200 without using helium gas

Supermini200 Application Notes

The following application notes are relevant to this product

-

BATT1008 - Impurity Analysis for Silicon Metal Anode Material

-

BATT1005 - Main Component Analysis for NCM Cathode Material

-

BATT1004 - Composition Analysis for Nickel Laterite

-

WDXRF1060 - Elemental Determination of Whole Coal by the Pressed Powder Method

-

WDXRF1081 - Analysis of Low-concentration Sulfur in Petroleum-based Fuels by Benchtop WDXRF according to ASTM D2622-16

-

WDXRF1047 - Highly Accurate Determination of Total Iron in Natural and Processed Iron Ores using Pressed Powder Method

-

WDXRF1063 - Thickness/composition of ITO Thin Film by FP Method

-

WDXRF1082 - Sulfur Analysis in Crude Oil and high-sulfur Fuels by Benchtop WDXRF according to ASTM D2622-16

-

WDXRF1090 - Semi-quantitative Analysis of Recycled Solid Fuel with Benchtop WDXRF Supermini200

-

WDXRF1059 - Semi-quantitative Analysis of Glass Raw Materials

-

WDXRF1036 - Semiquant Analysis by the SQX Scatter FP Method

-

WDXRF1062 - Quantitative Analysis of Soda-lime Glass

-

WDXRF1042 - Quantitative Analysis of Pow Alloy Steel using the Supermini200

-

WDXRF1055 - Quantitative Analysis of Aluminum Alloy on Supermini200

-

WDXRF1061 - Polymetallic Sulfide Ore Analysis with Supermini200

-

WDXRF1079 - Lubricating Oil Analysis by Benchtop WDXRF according to ASTM D6443-14

-

WDXRF1080 - Sulfur Analysis in Petroleum Products by Benchtop WDXRF According to ASTM D2622-16

-

WDXRF1116 - Lead Analysis in Gasoline — ASTM D5059-21 — using Benchtop WDXRF Supermini200

-

WDXRF1048 - Fused Bead Analysis for Wide Concentration Ranges of Various Oxide Materials on Benchtop WDXRF

-

WDXRF1092 - Fixed Angle Measurement using the Semi-Quantitative Analysis Function SQX of ZSX Guidance Software

-

WDXRF1058 - Quantitative Analysis of Dolomite and Limestone by Pressed powder Method with Supermini200

-

WDXRF1041 - Copper Concentrate by Pressed Powder Method

-

WDXRF1040 - Cement Raw Meal by the Pressed Powder Method

-

WDXRF1114 - Cement Analysis by the Pressed Powder Method on Benchtop WDXRF Supermini200 According to ASTM C114-18

-

WDXRF1115 - Cement Analysis by the Fusion Method on Benchtop WDXRF Supermini200 According to ASTM C114-18

-

WDXRF1052 - Accurate Determination for Elements in Laterite Ores by Pressed Powder Method

Supermini200 Resources

Webinars

Visit the Webinar resource page to access Webinars relevant to Supermini200

Rigaku Journal articles

Visit the Rigaku Journal resource page to access articles relevant to Supermini200

Publications

Visit the Publication Library to access articles relevant to Supermini200

Supermini200 Events

Learn more about our products at these events

-

EventDatesLocationEvent website

-

Pittcon 2026March 9 2026 - March 11 2026San Antonio, TX, USA

-

APS 2026March 16 2026 - March 20 2026Denver, CO, USA

-

ACS Spring 2026March 22 2026 - March 26 2026Atlanta, GA, USA

-

International Battery 2026March 23 2026 - March 26 2026Orlando, FL, USA

-

AnalyticaMarch 24 2026 - March 27 2026Munich, Germany

-

Chembio ExhibitionApril 15 2026 - April 16 2026Helsinki, Finland

-

MRS Spring 2026April 26 2026 - May 1 2026Hawaii, HI, USA

-

Canadian Chemistry Conf 2026May 24 2026 - May 28 2026Toronto, ON, Canada

-

3rd Global CemCCUS Conference, ExhibitioJune 9 2026 - June 10 2026Hamburg, Germany

-

Denver X-ray Conference (DXC) 2026August 3 2026 - August 7 2026Lombard, IL, USA

-

12th Pacific Rim International Conference on Advanced Materials and Processing (PRICM12)August 9 2026 - August 13 2026Gold Coast Queensland, Australia

-

ACS Fall 2026August 23 2026 - August 27 2026Chicago, IL, USA

-

MS&T 2026October 4 2026 - October 7 2026Pittsburgh, PA, USA

-

GSA 2026October 11 2026 - October 14 2026Denver, CO, USA

-

Gulf Coast Conference (GCC) 2026October 13 2026 - October 15 2026Galveston, TX, USA

-

AAPS PharmSci 360 - 2026October 25 2026 - October 28 2026New Orleans, LA, USA

-

SERMACS 2026November 4 2026 - November 7 2026Memphis, TN, USA

-

Eastern Analytical Symposium (EAS) 2026November 16 2026 - November 18 2026New Jersey

-

MRS Fall 2026November 29 2026 - December 4 2026Boston, MA, USA

-

Advanced Automotive Battery Conf 2026December 8 2026 - December 11 2026Las Vegas, NV, USA

Supermini200 Training

Upcoming training sessions

-

TitleDatesCostLocationNotesCourse outlineRegistration form

-

WDXRF training (USA)April 13 2026 - April 15 2026$5000Hybrid; The Woodlands

-

ZSX Primus IV & Supermini200 training (EMEA)September 14 2026 - September 16 2026Please contact ECOE@rigaku.comNeu-Isenburg, GermanyZSX Primus IV & Supermini200 training

-

WDXRF training (USA)October 19 2026 - October 21 2026$5000Hybrid; The Woodlands

-

ZSX Primus IV & Supermini200 training (EMEA)November 30 2026 - December 2 2026Please contact ECOE@rigaku.comNeu-Isenburg, GermanyZSX Primus IV & Supermini200 training

Supermini200

Testimonials

-

I like Supermini for its high sensitivity to the light elements as well as its high resolution...and all these are available with its benchtop packaging thanks to its high-powered generator and the WDXRF configuration.

Read the full testimonialTakamitsu SugiharaCenter of Deep Earth Exploration (CDEX) -

Compared with conventional methods of analysis, the Supermini is safe, quick, and user-friendly, and is sure to supersede the traditional analytical methods.

Read the full testimonialJason Hubbard and Cameron NixALS Coal

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.