Memory

Memory application metrology solutions address process requirements for film thickness and composition as well as surface contamination monitoring and process requirements for film thickness and composition.

Trust Rigaku Solutions for the best X-ray metrology services to ensure quality, consistency, and reliability of your semiconductor memory device manufacturing processes. Optimize your manufacturing processes and enhance device performance with our precise characterization of film thickness, composition, and surface contamination.

PRAM (GST)

Film Thickness and Composition: Rigaku metrology solutions offer various analytical approaches such as WDXRF (wavelength dispersive X-ray fluorescence), XRR (X-ray reflectometry), and EDXRF (energy dispersive X-ray fluorescence) to characterize PRAM (GST) materials. These methods help in determining film thickness and composition accurately.

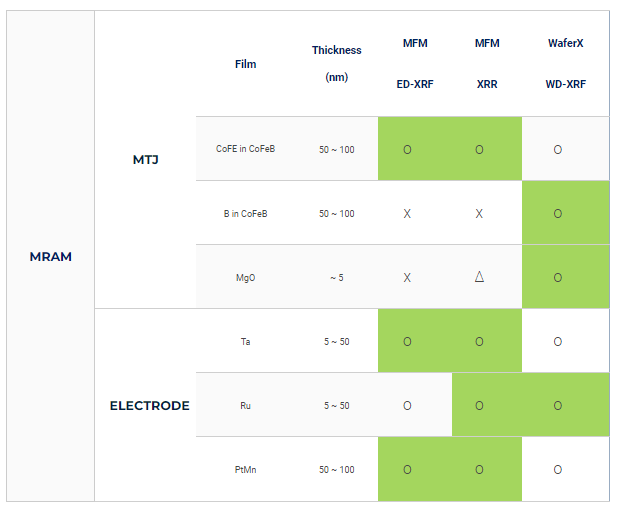

MRAM

Film Thickness and Composition: Similar to PRAM, Rigaku metrology solutions cater to the process requirements for MRAM in terms of film thickness and composition analysis. This involves employing techniques like X-ray fluorescence. Additionally, Rigaku's solutions for MRAM metrology include surface contamination monitoring. This aspect is critical for ensuring the quality and reliability of MRAM devices by detecting and mitigating any contaminants on the surface of the materials.

X-ray metrology solutions

Where precision meets efficiency

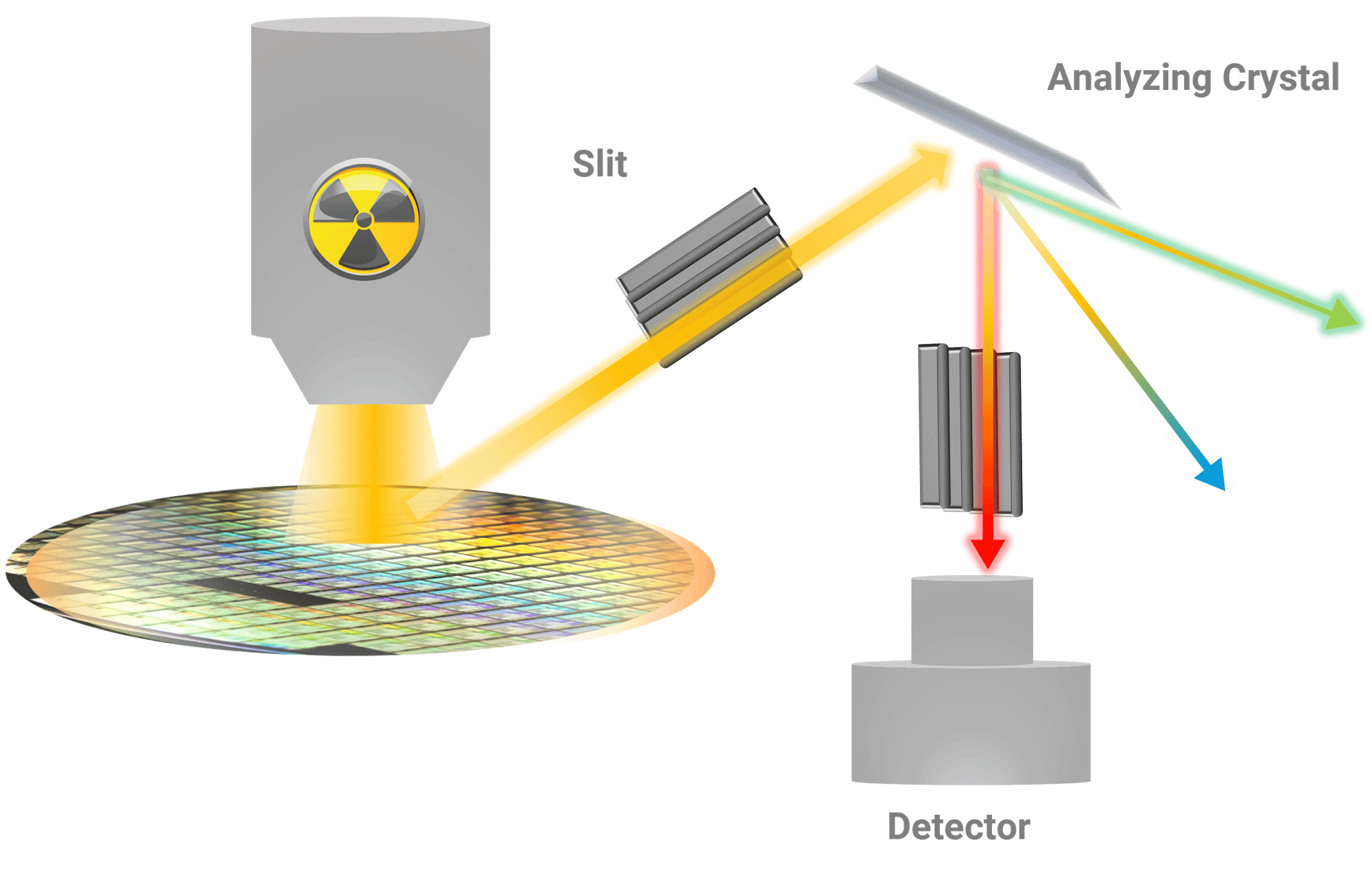

WDXRF | AZX 400

Rigaku metrology solutions address process requirements for film thickness and composition. Here we describe different analytical approaches to characterize PRAM (GST) materials by WDXRF versus XRR & EDXRF. General features of Rigaku WDXRF systems, like the AZX 400, are shown below.

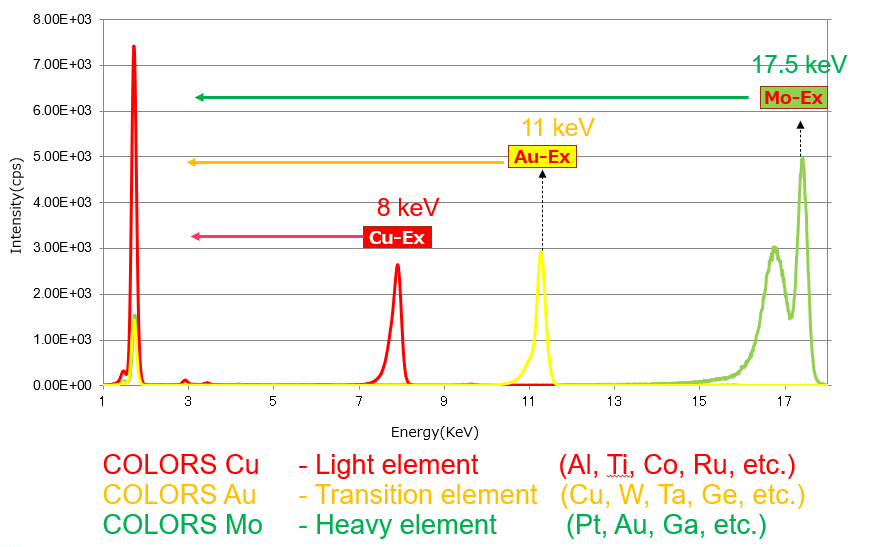

EDXRF and XRR | XTRAIA MF-3000

Rigaku's XTRAIA MF-3000 employs three COLORS monochromatic beam modules for EDXRF measurements of light, transition, and heavy elements. EDXRF measurements can be made over a range of incidence angles, and the ability to perform grazing incidence XRF measurements enhances sensitivity for ultrathin films.

Features of Rigaku WDXRF tools

Measurable elements

- Be - U

- Measure ultra-light elements such as B, C, N, and O.

- Measure Mg and Al with high resolution.

Quantitative method

Advanced FP Method FP (Fundamental Parameter) method enables thickness and composition analysis with one recipe.

Analyzable structure

- Analyze up to 20 stacked layers.

- The FP method considers the absorption by other layers.

- Analysis of complex compounds or multi-layered samples.

Analyzable thickness

- Sub-angstrom (Å) to micron (μm) level

- High-power X-ray tubes (4 kW) can excite multiple lines for most elements.

- Our systems address a wide range of thicknesses.

EDXRF and XRR

Features of XTRAIA MF-3000

MRAM process measurement

The table below describes thickness and composition measurement possibilities.

Analysis condition:

- CoFeB thickness can be measured by XRF in the case of constant composition.

- CoFeB composition measurement by Co and Fe. B could not be measured.

- Compositions were calculated by the Fundamental Parameters (FP) Method.

Recommended solutions

Explore our range of solutions and unlock the potential for precise material analysis that drives innovation and quality assurance in your processes

Contact Us

Whether you are interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.