Application Note RSMD-20101936

PCB panel

Introduction

Seed copper is deposited during the PCB manufacturing process, often over other Cu layers, a process that requires accuracy in the thickness of this thin layer. Measurement of the seed layer thickness for quality assurance is available using Energy Dispersive X-ray Fluorescence (EDXRF), which overcomes the challenge of differentiating seed copper from the Cu layer beneath.

XRF Analysis

- XRF results of sample surface

- The following elements were detected: Cu, Al, Si, S, Fe, Ni, Cu

- Further analysis examples:

- Light element detection

- What other elements should be expected?

Acquisition time: 30 sec

Acquisition time: 30 sec

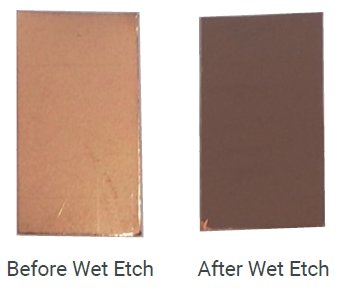

Wet etch

- Etch performed by dipping the sample (for one minute) in a solution containing:

- H₂0₂ (3%)

- Citric acid

- NaCl

Measurement objective

To measure the thickness of the top, electroless-deposited Cu seed layer at several sample locations.

Electroless Cu seeding (1 µm)

- ABF, Ajinmoto Build-up Film, is a carbon-based epoxy film developed by Ajinmoto Co.

- FR-4, flame retardant class 4, is a type of laminated substrate material used in the manufacture of printed circuit boards (PCBs).

Top Cu layer isolation

- The top Cu layer was removed from one of the samples using wet etch.

- XRF comparison was made between etch and non-etch samples.

- Cu Lα comes only from the top Cu layer.

Cu Lα saturation test

- For the top Cu layer, 1 µm is much below the saturation depth.

- Saturation in XRF is a specific depth of the layer whereby intensity no longer changes beyond this layer thickness.

- Thickness changes correlate to changes in the current.

- XRF measurement was performed at the same location using varying currents in order to determine the ideal linear section of the intensity vs. current curve.

Cu thickness sample comparison

- XRF scan was performed over six points (1 mm step) on three different samples.

- Cu Lα peak intensity was compared.

- The average intensity of Samples B and C were used as reference with thickness of 1 µm.

- Sample A has significantly thinner top Cu layer than Samples B and C.

- The top Cu layer of Samples B and C has uniform thickness, unlike Sample A.

Cu intensity

Intensity vs. current

Across-wafer variation

Cu layer thickness [µm]

| Point | Sample A | Sample B | Sample C |

| 1 | 0.42 | 1.00 | 1.00 |

| 2 | 0.52 | 1.01 | 1.01 |

| 3 | 0.64 | 1.01 | 1.01 |

| 4 | 0.65 | 1.01 | 0.98 |

| 5 | 0.74 | 0.97 | 1.01 |

| 6 | 0.78 | 0.99 | 0.99 |

| Average | 0.62 | 1.00 | 1.00 |

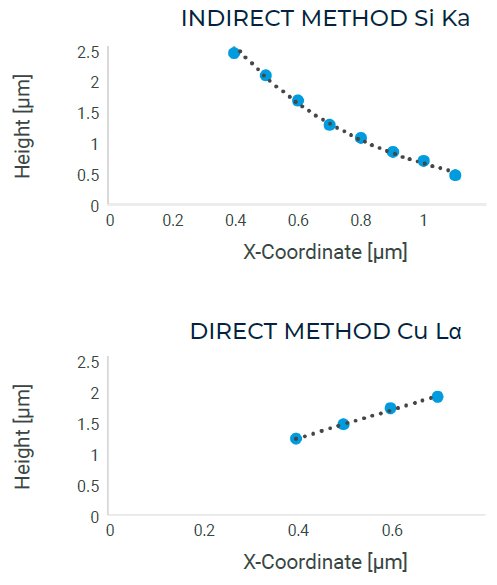

Cu seed thickness measurement by direct and indirect methods

- Cu layer thickness is measured by an automated algorithm using two methods.

- Direct method (0–0.7 µm) measuring the Cu Lα peak and calculating Cu layer thickness using linear regression

- Indirect method (0.7–1.4 µm) measuring the Si Kα peak and calculating Cu layer thickness using exponential regression

- Cu Lα peak intensity is saturated due to its low energy (0.93 keV), so the Cu layer thickness is measured indirectly using the Si from the ABF layer.

- Cu Lα and Si Lα were clearly detected by the EDXRF.

- Cu upper layer thickness can be monitored by using both peaks independently – Cu Lα or Si Kα peaks.

- Acquisition time: 12 sec

| Nominal [µm] | Direct Method [µm] | Indirect Method [µm] |

| 0.4 | 0.398 | 0.382 |

| 0.5 | 0.496 | 0.462 |

| 0.6 | 0.613 | 0.571 |

| 0.7 | 0.689 | 0.704 |

| 0.8 | - | 0.788 |

| 0.9 | - | 0.888 |

| 1.0 | - | 0.960 |

| 1.1 | - | 1.083 |

Regression curves

- Linear regression for the direct method

- Exponential regression for the indirect method

Roughness

- 3D scanner was used for measuring roughness by measuring surface height variations.

- Height variation up to 2 µm

3D scan imaging

2D microscope image

Summary

Summary

- XRF is very sensitive to thickness variation up to 0.1 nm. Many elements can be analyzed, qualitatively and quantitatively.

- Top Cu layer thickness can be measured using Cu Lα peak intensity changes.

- For accurate results, standards are required.

- The 3D scanner can monitor surface roughness.