TXRF Metrology Tools

Total Reflection X-ray Fluorescence. TXRF SERIES metrology tools offer significant advantages in semiconductor manufacturing and R&D to evaluate surface contamination. Non-destructive TXRF measurements are highly sensitive to trace elements, including Na, Mg, and Al, transition metals, and heavy elements. Integrated Vapor-Phase Decomposition (VPD) capability available in the TXRF-V310 and XHEMIS TX-3000V enables the lowest detection limits. They are sensitive to trace elements, highly sensitive, and capable of quantitative analysis. These non-destructive tools excel in analyzing thin films, provide valuable insights into their elemental composition and thickness, and contribute to enhanced quality control, optimized processes, and a deeper understanding of materials.

TXRF Series

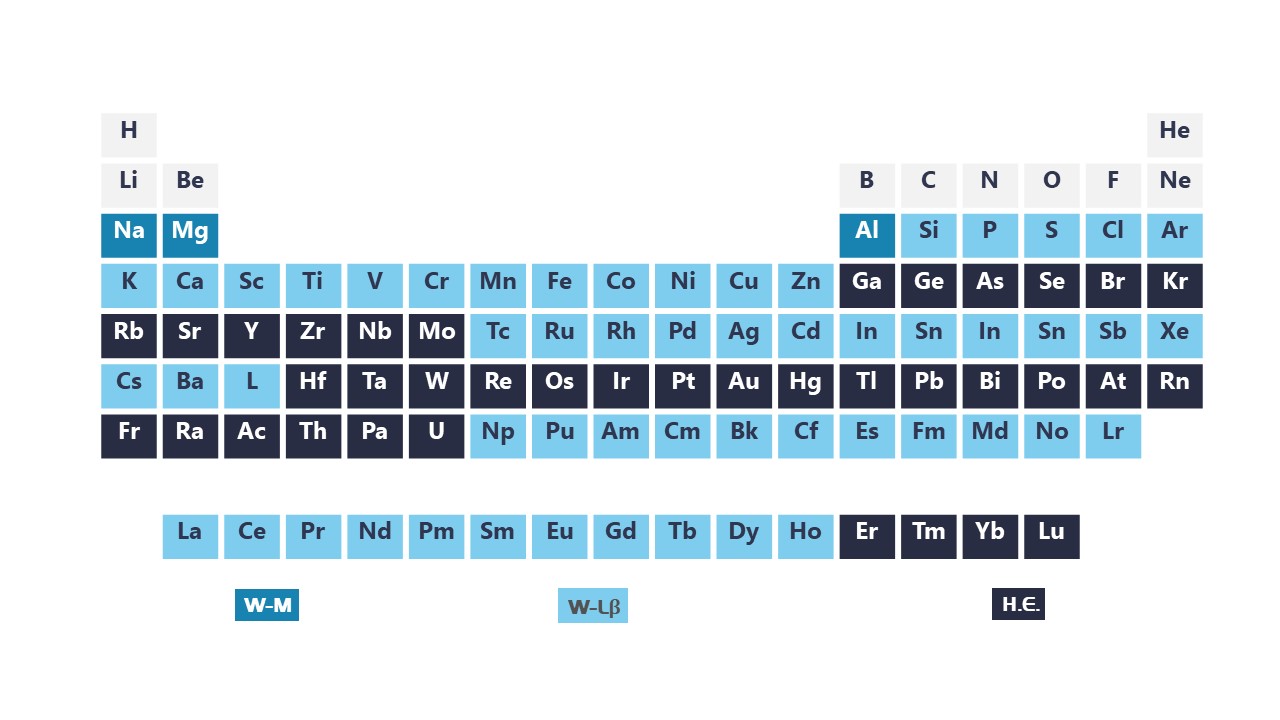

Non-destructive TXRFmeasurements are highlysensitive to trace elements,including Na, Mg, and Al,transition metals, andheavy elements.

TXRF 310Fab

TXRF spectrometer for high-volume manufacturing with The Highest Throughput Wafer Surface Contamination Metrology

Learn more >TXRF-V310

Integrated VPD-TXRF spectrometer for the highest sensitivity wafer surface contamination metrology

Learn more >XHEMIS TX-3000

TXRF Metrology System metal contamination analyzer with integrated VPD with ultra high-speed metal contamination mapping

Learn more >TXRF Application Sample

Evaluation of spatial distribution of contamination on wafer surfaces by TXRF

TXRF spectrometers are widely used to measure contamination in the semiconductor fabrication process. TXRF technique allows non-destructive analysis for most all elements (Na~U) in the periodic table. TXRF spectroscopy is possible due to the property of X-rays as they irradiate the surface of a wafer. Each material has a unique critical angle. If the incident angle of the X-rays is above the acute angle, the X-rays penetrate the surface deeply; if the incident angle is smaller than the critical angle, total reflection occurs. In the total reflection condition, fluorescence X-rays will occur only from contamination on the surface, and the substrate material will not add background noise to the measurement. The penetration depth of the incident X-rays under the conditions of total reflection is theoretically around 5 nm, and thus TXRF is classified as a surface analysis technique.

Compound Semiconductors

Evaluation of Wet Cleans in SiC Power MOSFET Fabrication by TXRF.

TXRF MEASUARABLE ELEMENTS

Contact Us

Whether you are interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.