Application Note SMX027

Introduction

Powder diffraction experiments are traditionally carried out with dedicated powder diffractometers. These are designed for the use of relatively large amounts of sample (>> 20 mg). The larger line-focused beam probes the sample’s bulk nature by illuminating a large volume of material. However, if only micrograms of sample are available, the sample volume is too small to use standard powder diffractometers. With specific optics and sample holders, powder microdiffraction is viable, but not every laboratory is equipped with them or is able to change the system configuration easily. The micro-focus high-brilliance X-ray sources and high-performance detectors used in Rigaku Oxford Diffraction XtaLAB Synergy systems enable users to collect microdiffraction data without any configuration changes and with data collection times and quality on par with dedicated powder diffractometers.

XtaLAB Synergy single crystal diffractometers can even exceed the scope of usual powder instruments. They are regularly equipped with non-ambient temperature devices. The recording of high-quality powder diffraction data is furthermore supported by the automatic divergence control, accessible only with XtaLAB Synergy systems.

The versatile CrysAlisPro software contains all necessary plugins for powder measurements, processing and evaluation. By utilizing CrysAlisPro and XtaLAB Synergy systems, single crystal dedicated laboratories can easily extend their scope of samples to polycrystalline phases.

Drug development is one typical use-case for measurement of micrograms of powder. Therefore, the characterization of active pharmaceutical ingredients (APIs) is featured in this study. Such analysis can easily be adopted by research groups involved in the development of new API or functional materials.

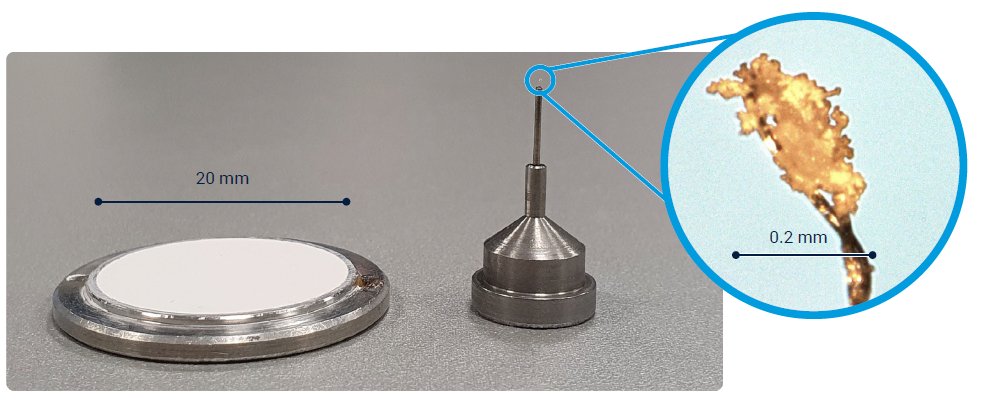

Figure 1: Standard powder sample on Ø20 mm sample holder and microscopic powder sample on Ø0.2 mm single crystal mount.

Quick phase identification of an organic API with XtaLAB Synergy-S (Cu/Mo) system

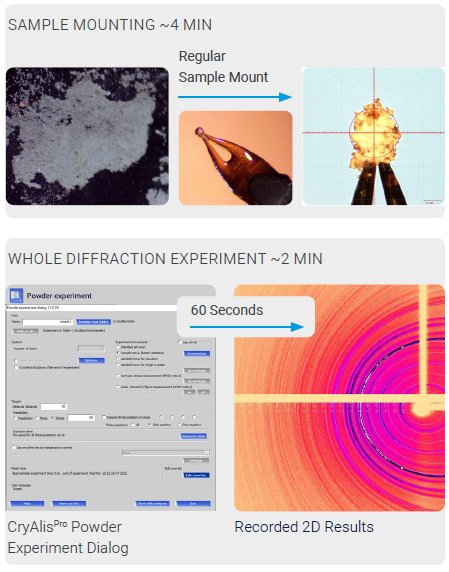

Phase identification of organic polycrystalline materials can be achieved in a matter of minutes, without any time-consuming sample preparation or mounting techniques, with the help of the XtaLAB Synergy-S equipped with high-brilliance PhotonJet Cu Kα microfocus source and a HyPix 6000 detector, Figure 2 and Figure 3.

Figure 2: Micro powder diffraction workflow with XtaLAB Synergy-S (Cu/Mo) and CrysAlisPro.

Figure 3: Extracted 1D experimental diffraction pattern of naproxen overlayed with calculated pattern based on PDF4-Organics entry 20642110 in CrysAlisPro.

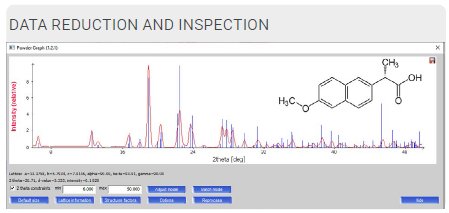

Ease of sample preparation

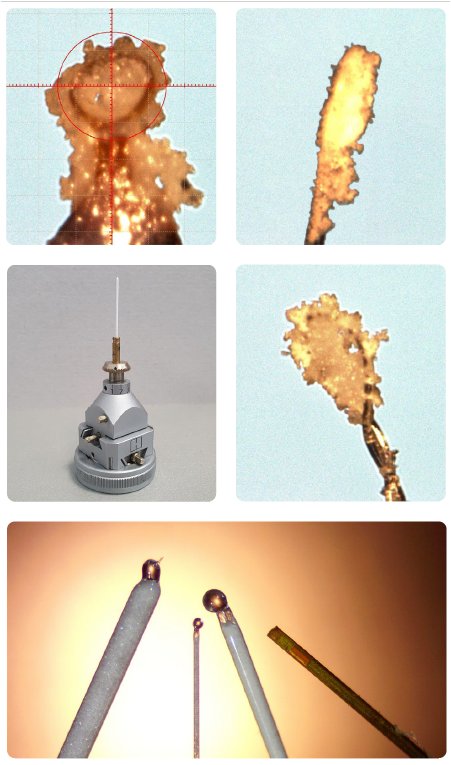

Preparation of powder samples on single-crystal mounts is very easy and straight forward. Using a drop of oil, the powder sample sticks to the loops. Alternatively, quartz or Kapton® capillaries can be used as shown in Figure 4. The samples can be mounted on magnetic bases or standard mounts and easily centered in the beam, just like a single crystal.

Figure 4: Powder samples on Kapton and nylon loops and in quartz and Kapton capillaries.

Rigaku’s HyPix technology advantage

XtaLAB Synergy systems come equipped with Rigaku HyPix detectors as standard. Hybrid X-Ray Photon Counting (HPC) detectors are considered high-end for dedicated powder diffractometers, e.g., the SmartLab (Figure 5). The benefits, such as high dynamic range, single photon sensitivity, excellent spatial resolution, zero noise and single-pixel point spread function, are well proven and tested by the powder and thin layer XRD community.

Figure 5: A SmartLab’s HyPix-3000 next to XtaLAB Synergy’s HyPix-Arc 150º, both using HPC technology.

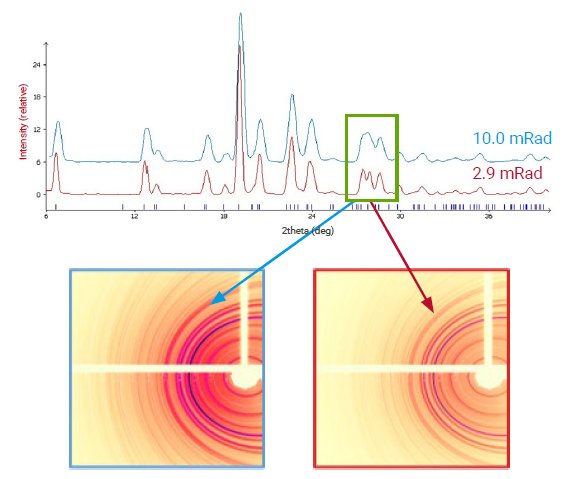

Continuously variable divergence control improves peak resolution

Microfocus sources, by design, use convergent beams to increase flux-density. This means the beam diverges after the sample, which can be undesirable. Although HyPix detectors have excellent spatial resolution suitable for quick phase identification at short detector distances, for complex mixtures or low symmetry materials this can result in peak overlap. Longer detector distances may improve resolution but with limited success. PhotonJet Cu sources can be equipped with a divergence control slit as an option. A simple software slider in CrysAlisPro allows the divergence to be adjusted down to 1 mRad, which can dramatically improve peak shape and thus data quality, as shown in Figure 6.

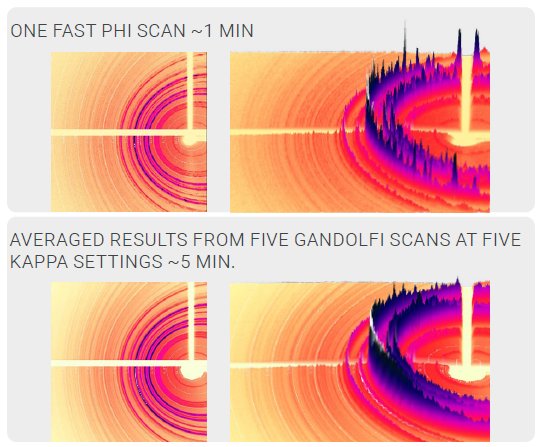

Data collection with Gandolfi scans randomizes the sample orientation in the beam, by driving both phi and omega circles at the same time. If required, the scan can be repeated for different kappa settings. The calculation of possible scans and data integration is done automatically by CrysAlisPro software. Some exemplary results from this procedure are shown in Figure 7.

Figure 6: Reducing beam divergence improves peak resolution. A broad, ill-defined peak with the raw beam (blue) is resolved into two peaks when using low divergence (red)

Hardware solution for sample quality issues

Good sample preparation is crucial in powder measurement and analysis. Proper sample grinding and randomization of the crystallite orientation is even more important for small samples. However, in the case of some organic materials, grinding can lead to amorphization or is simply not possible due to limited sample availability. To minimize influence of prefered orientation, the Gandolfi Method can be easily applied with the XtaLAB Synergy Universal Goniometer.

Figure 7: Application of Gandolfi scans on flufenamic acid sample. (XtaLAB Synergy-S (Cu/Mo); detector distance: 60 mm, exposure time: 60 s per scan).

Software advantages of CrysAlisPro

Constant improvement inspired by users led to the development and inclusion of dedicated powder data processing tools in CrysAlisPro. These tools allow for the extraction of high-quality 1D powder diffraction pattern from 2D diffraction images. The algorithm accounts for instrument model adjustments and provides background removal and baseline correction options, as well as multiple modes of pattern extraction. Quick phase match with known structure factors as graphical representation of measured and literature pattern are fully implemented within the software.

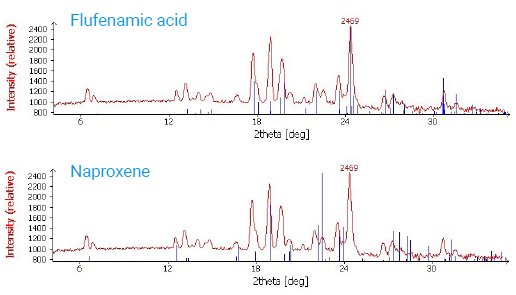

New phase or just a mixture?

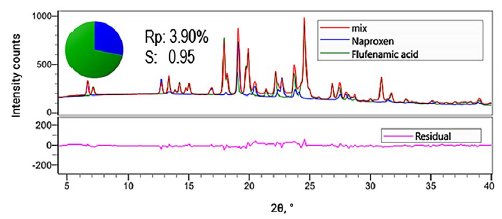

Quick screening of a sample revealed additional intensities next to the expected pattern (Figure 8). Overlaying peak prediction markers for a suspected contaminant within CrysAlisPro allows for quick confirmation of their presence. An extended measurement of the same mixture in Figure 9 allows for Rietveld refinement in dedicated programs.

Figure 8: Screening flufenamic acid/ naproxen mixture on a XtaLAB Synergy-S Cu at 190 mm, 2.9 mRad, 180 s

Figure 8: Screening flufenamic acid/ naproxen mixture on a XtaLAB Synergy-S Cu at 190 mm, 2.9 mRad, 180 s

Figure 9: Rietveld refinement indicates a 2:1 flufenamic acid/ naproxen mixture on a XtaLAB Synergy-S Cu at 190 mm, 1.0 mRad, 1 h)

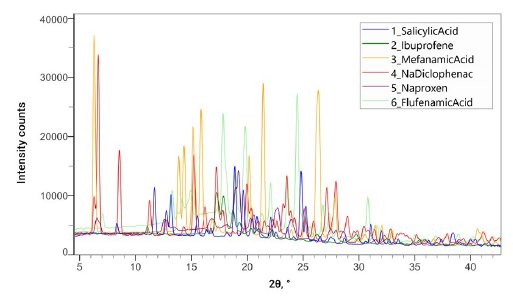

Figure 10: Screening of six APIs on XtaLAB Synergy-S Cu at 120 mm, 3.3 mRad, 60 s each)

Additional benefits of using XtaLAB Synergy systems

- Quick and easy sample centering with a video camera on the system

- Variable temperature studies with existing cryo-device

- XRF suppression with any HyPix detector.

- Switch radiation source with DW or dual source systems.

- Employ XtalCheck-S for automated powder screening

- PDF analysis accessible due to versatile goniometer.

Conclusions

XtaLAB Synergy single crystal diffractometers are excellent instruments for collecting powder microdiffraction data from very small amounts of organic API materials. A XtaLAB Synergy diffractometer and CrysAlisPro allow for quick identification of mixtures and new crystalline phases.