Crystallinity Analysis

Crystallinity is one of the key factors that determine the properties of materials. It is defined as the percentage of the material that has a “crystalline structure” in which atoms and molecules are regularly arranged. The mechanical and thermal properties of a material change according to this value. For example, in polymer materials, higher crystallinity leads to better strength and heat resistance, while in pharmaceuticals, crystallinity affects the solubility and absorption rate of drugs. One method for quantitatively evaluating crystallinity is X-ray diffraction (XRD).

Crystallinity analysis using X-ray diffraction

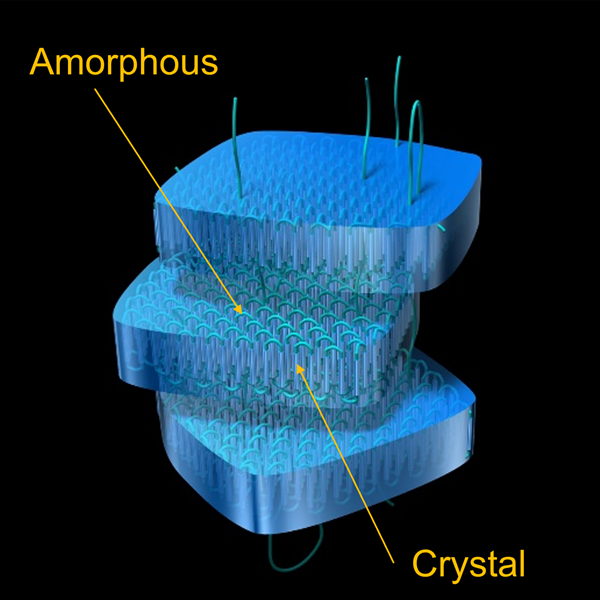

X-ray diffraction involves irradiating a sample with X-rays and analyzing the resulting diffraction pattern to obtain information about the crystalline structure. Crystalline regions produce sharp peaks because the atoms are arranged regularly, whereas amorphous regions scatter X-rays broadly, resulting in diffuse halos. This difference in XRD patterns is used to calculate the crystallinity, which is the percentage of crystalline regions in the sample.

The degree of crystallization (Xc) is calculated using the following formula based on the X-ray diffraction spectrum, which separates the peak intensity from total crystalline regions (Ic) and the scattered intensity from amorphous regions (Ia):

Xc (%) = (Ic / (Ic + Ia)) × 100

In simpler terms, Crystallinity (%) = Amount of crystalline material / Total amount of material ×100

This method is widely applied across various fields, including polymers, metals, ceramics, semiconductors, and pharmaceuticals.

X-ray diffraction-based crystallization analysis is an indispensable technique for quality control and research in material development. Utilizing this method can significantly contribute to improving product performance and developing new materials.

Rigaku recommends the following products

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.