Preferred Orientation Analysis

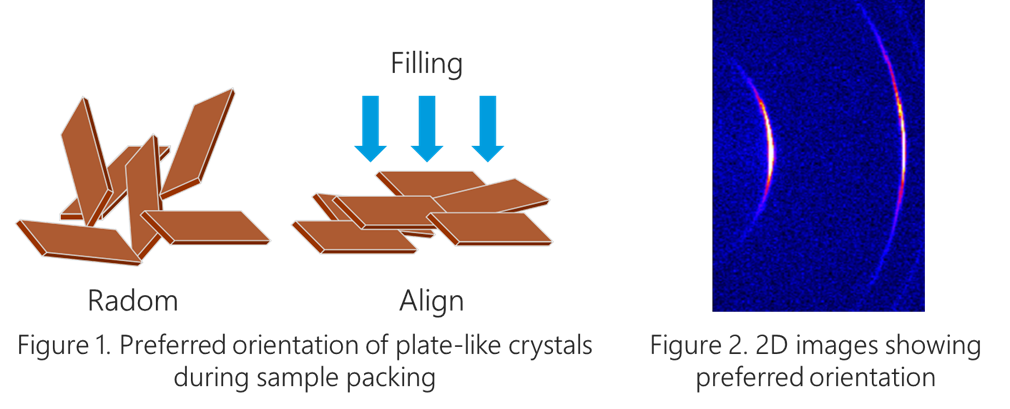

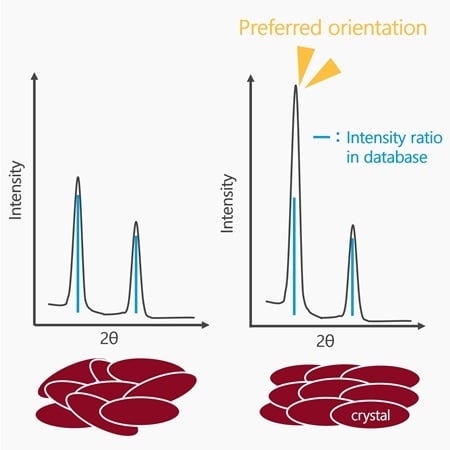

In powder X-ray diffraction (PXRD), sample preparation involves flattening the sample surface and filling it into the sample holder by scraping off any excess material to ensure it is level with the surface of the sample holder. When the crystalline grains of the sample have anisotropic shapes, such as needle-like or plate-like structures, specific lattice planes tend to align preferentially during the filling process (Figure 1). This phenomenon is known as preferred orientation. When preferred orientation occurs, the intensity ratios of diffraction peaks in the XRD pattern deviate from their true (or database) values, affecting the accuracy of quantitative analysis, particularly when using integrated intensity.

To correct this effect, WPPF (whole powder pattern fitting) methods, such as Rietveld refinement, commonly incorporate functions to account for intensity bias caused by preferred orientation. Proper correction mitigates the impact of preferred orientation, enabling more accurate quantitative phase analysis.

The presence or absence of preferred orientation can be evaluated using images of Debye rings obtained with a two-dimensional detector or by rocking curve measurements. In randomly oriented samples, the intensity distribution of the Debye rings is uniform. However, when preferred orientation is present, certain areas of the rings become more pronounced, resulting in an uneven pattern (Figure 2). Additionally, in a rocking curve measurement, diffraction intensity is recorded while varying the incident angle (ω) at a specific diffraction angle, allowing an assessment of the degree of crystal orientation. Randomly oriented samples exhibit a constant intensity profile, whereas samples with preferred orientation show a sharp increase in intensity at specific ω angles. However, the sensitivity of rocking curve measurements to preferred orientation is relatively low.

Minimizing preferred orientation during sample preparation is important, but appropriate corrections improve the accuracy of quantitative analysis. This correction is particularly critical in the analysis of highly oriented materials, such as cement and clay minerals.

Rigaku recommends the following products

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.