In-situ measurement

In-situ measurement allows real-time observation of how a sample responds to external conditions. This method is useful for evaluating structural and property changes in materials under varying environmental conditions. Unlike conventional measurements, where a sample is kept under fixed conditions to avoid external influences, in-situ measurement alters parameters such as temperature, pressure, electric fields, humidity, and gas atmosphere to more accurately simulate real-world conditions.

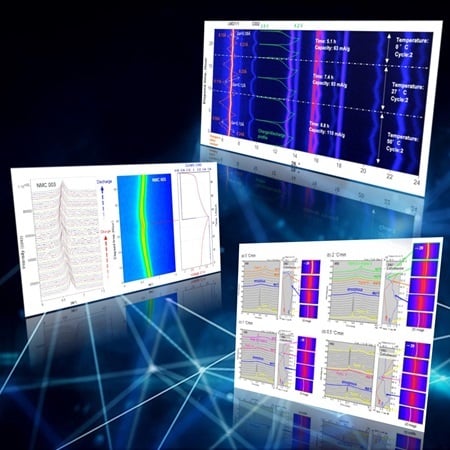

X-ray diffraction (XRD) is widely used for in-situ measurements because it provides real-time information on a material’s crystal structure.

In-situ XRD is applied in various fields, including battery research, catalysis, metallurgy, semiconductor development, and high-temperature material studies. For example, simultaneous XRD measurements of battery materials clarify changes such as phase transitions and material degradation while charging and discharging. These observations are essential for improving battery performance, capacity retention, and lifespan. Therefore, researchers can optimize battery materials for enhanced efficiency and stability, ultimately leading to the development of next-generation energy storage systems. Another example is XRD-DSC (Differential Scanning Calorimetry), which combines XRD with thermal analysis. This approach is useful for studying phase changes caused by temperature variations, particularly in pharmaceutical and polymer materials. It provides insights into thermal stability, phase transformation temperatures, and material compatibility.

In-situ XRD measurements are also used to analyze powdered and thin-film samples. Powder XRD helps determine phase composition and track phase transitions and chemical reactions in real time. For thin films, in-situ XRD allows evaluation of the crystallization process during film deposition or thermal treatment, making it valuable for semiconductor and materials research.

In-situ XRD measurements contribute to material science by capturing material structure in real time. This method enhances the understanding of material behavior under operating conditions, leading to more efficient and durable materials for research and industrial applications.

Rigaku recommends the following products

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.