Application Note B-XRD2003

Introduction

As next-generation ultrahigh-density magnetic recording media, granular thin films in which metal microparticles are dispersed have been a focus of attention. Among these films, the regular phase (tetragonal crystal) of FePt has a particularly high magnetic anisotropy as well as good corrosion and oxidation resistance, so it is expected that it will be applied to actual devices. However, the irregular phase (cubic crystal) is created at the same time, depending on the film-forming conditions. For this reason, a technique to distinguish these crystalline phases at the nanoparticle and thin film level is required. Using the in-plane X-ray diffraction method, in which X-rays are irradiated on the surface of a thin film sample at a glazing angle to study the regular structure (crystal structure) in the in-plane direction, it is possible to identify the crystalline phase even for ultrathin films of only a few nm in thickness. It is also possible to analyze the sample in the depth direction by changing the incident angle of X-rays entering the sample surface.

Measurements and results

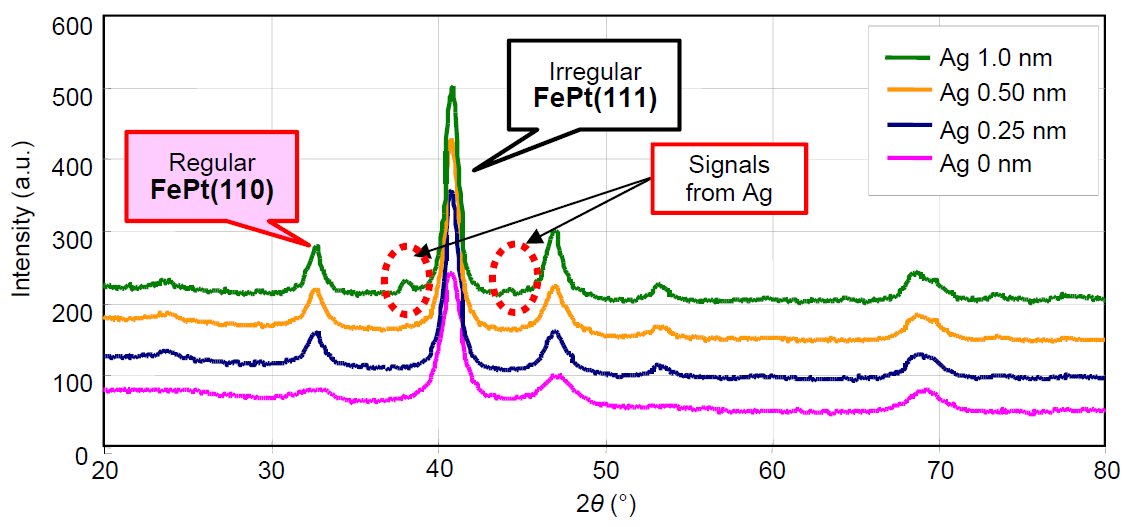

Figure 1 shows the in-plane diffraction profiles of a sample where a FePt film of 15 nm in thickness is formed on a glass substrate on which a silver (Ag) layer is deposited in four different thicknesses. As the Ag film thickness increases, crystallization of the FePt regular phase advances. Signals from the Ag layer, which is only 1 nm in thickness, are also detected (1), (2).

Figure 1: In-plane diffraction profile of a FePt film with Ag layers that vary in thickness

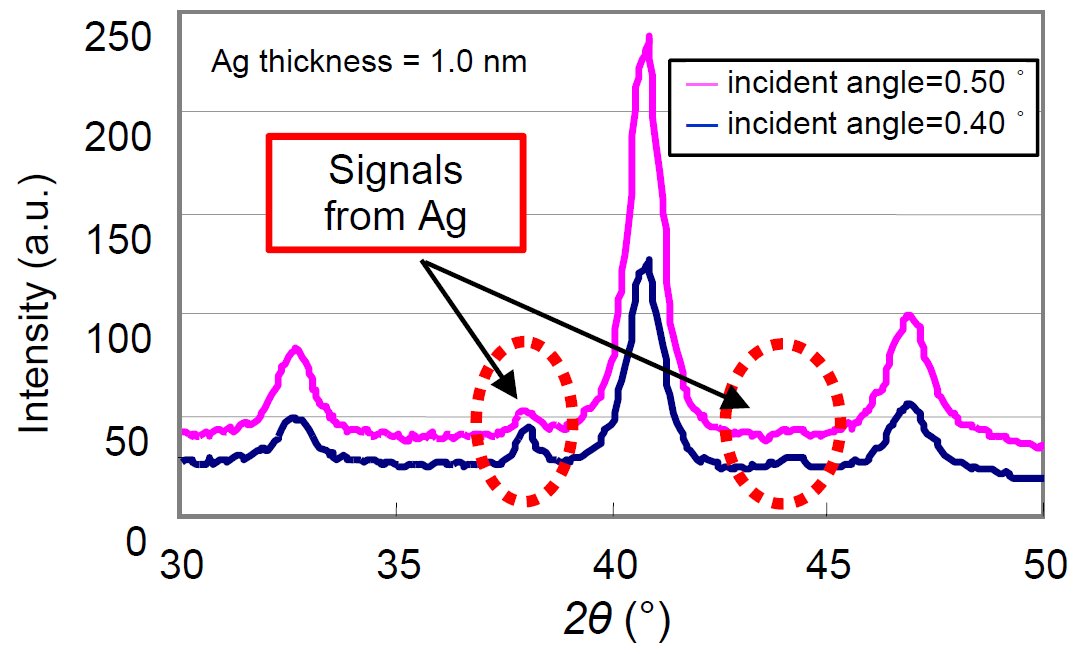

Figure 2 shows the results of a diffraction experiment where the incident angle is changed on a sample that is a 1 nm thick Ag layer on a glass substrate. When the incident angle is shallow, the signals become relatively strong, suggesting that the silver (Ag) exists in the surface layer of the sample.

Figure 2: Dependence on the incident angle

References:

(1) Z. L. Zhao et al: Appl. Phys. Lett., 83(2003) 2196-2198.

(2) Z. L. Zhao et al: J. Appl. Phys., 95(2004) 7154-7156.