Application Note WDXRF1100

Introduction

The fusion method in X-ray fluorescence (XRF) analysis is an effective sample preparation technique for getting accurate analysis results of powder samples, since the technique eliminates heterogeneity due to grain size and mineralogical difference. In addition, the homogenization of material property by vitrification makes it possible to expand the calibration range by the use of synthetic standards of fused beads with reagents or by using diverse reference materials.

Rigaku provides an analysis package for various oxide materials by the fusion method, named "OXIDE-FB-PAK".

This application note introduces OXIDE-FB-PAK and demonstrates analysis results using this analysis package.

Precalibration package "OXIDE-FB-PAK"

OXIDE-FB-PAK is a "pre-"calibration package, which provides a quantitative application set including calibration, measurement conditions and analysis parameters. Since the pre-calibration package is pre-installed at our factory, analysis work can start soon after the system installation is completed. OXIDE-FB-PAK is established with 44 certified reference materials by the fusion method.

Using this package, quantitative analysis of 23 components can be carried out. Three multi-element glass disks included in the package are used for maintenance of the calibration curves.

This package is applicable for various oxide materials, such as rock, mineral, ore, slag, refractory or cement. The package is designed for the use of two kinds of lithium borate flux; one is 100% lithium tetraborate (LT) and the other is the mixture of 66% lithium tetraborate and 34% lithium metaborate (LM). The former is suitable for alkaline (basic) samples, including high content of alkali metal or alkaline earth metal elements, or for samples containing components easily crystallized, while the latter is effective for acidic oxides owing to their high dissolution property. The package has calibration for each of these fluxes.

The contents of OXIDE-FB-PAK are as follows:

- Drift correction samples

- XRF monitor glass disks, 3 pcs.

- Bias correction samples

- Pure silica with LT 100%, 1 fused bead

- Validation powder samples

- RM powder, 3 bottles (10 g each)

(alumina sand, iron ore, cement)

- RM powder, 3 bottles (10 g each)

- Calibration check samples

- Alumina sand with LT 100%, 1 fused bead

- Alumina sand with LT 66%/MT 34%, 1 fused bead

- Flux

- LT 100%, 1 bottle (100 g)

- LT 66%/MT 34%, 1 bottle (100 g)

- Non-wetting agent

- Lithium bromide, 1 bottle (50 g)

- Backup CD

- calibration curves (calibration constants) for LT 100% and LT 66%/LM 34%

- correction coefficients

- measurement conditions

- other application setting

- Instruction manual

The contents of the backup CD is pre-installed on the system to be shipped. Users do not have to install the contents at installation of the system.

Instrument

OXIDE-FB-PAK is applicable to Rigaku sequential wavelength-dispersive (WD) XRF spectrometer, ZSX Primus IV, ZSX Primus IVi and ZSX Primus III NEXT. "Fusion Bead Correction" optional program is required. In the case of ZSX Primus III NEXT, the optional Ge crystal is also required.

Calibration and CRMs

Total 44 certified reference materials (CRMs) and secondary standards from Fluxana and BAS were used to establish the calibration of OXIDE-FB-PAK. Calibration curves for 23 components were established.

The summary of the calibration is shown in Table 1. Theoretical alpha correction, overlap correction and background ratio correction were applied if required. The theoretical alphas were calculated using Fusion Bead Correction optional program, including LOI/GOI correction (LOI: loss on ignition, GOI: gain on ignition) and dilution ratio correction.

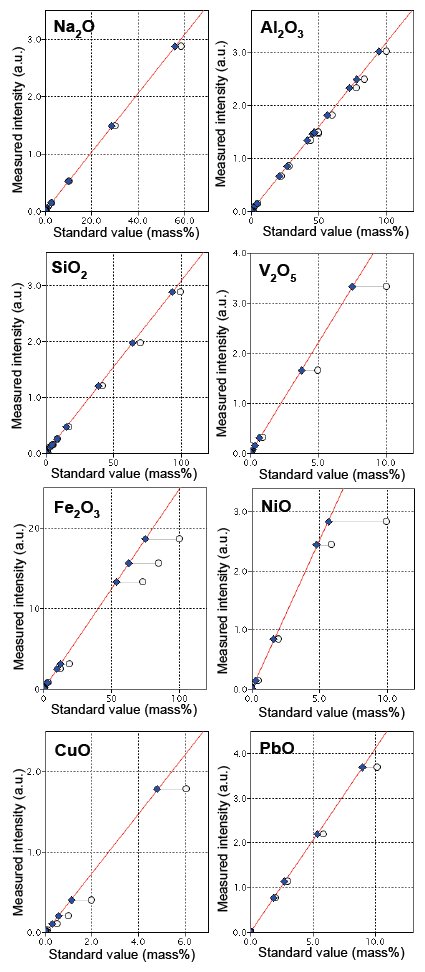

Representative calibration curves (Na₂O, Al₂O₃, SiO₂, V₂O₅, Fe₂O₃, NiO, CuO and PbO) are shown in Figure 1.

The accuracy of calibration was calculated by the following formula:

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-m} }$

$C_i$: calculated value of standard sample

$\hat{C}_i$: reference value of standard sample

n : number of standard samples.

m: degree of freedom (linear 2, quad. 3)

Table 1: Calibration summary.

| Component | Concentration range (mass%) | Accuracy (mass%) | Correc.*2 |

| Na₂O | 0.04 – 10 | 0.082 | A, L |

| MgO | 0.021 – 95 | 0.11 | A |

| Al₂O₃ | 0.004 – 100 | 0.10 | A |

| SiO₂ | 0.005 – 100 | 0.10 | A |

| P₂O₅ | 0.003 – 41 | 0.033 | A |

| SO₃ | 0.005 – 58 | 0.79 | A |

| K₂O | 0.003 – 56 | 0.19 | A |

| CaO | 0.004 – 99 | 0.23 | A |

| TiO₂ | 0.006 – 50 | 0.02 | A, L |

| V₂O₅ | 0.005 – 10 | 0.019 | A, L |

| Cr₂O₃ | 0.002 – 5 | 0.048 | A |

| Mn₂O₃ | 0.002 – 41 | 0.016 | A |

| Fe₂O₃ | 0.001 – 100 | 0.08 | A |

| NiO | 0.001 – 1 | 0.020 | A |

| CuO | 0.001 – 6 | 0.017 | A |

| ZnO | 0.001 – 10 | 0.030 | A |

| Rb₂O | 0.001 – 1 | 0.009 | B |

| SrO | 0.014 – 20 | 0.032/0.016 *1 | A, L / B *1 |

| Y₂O₃ | 0.001 – 1 | 0.009 | L, B |

| ZrO₂ | 0.006 – 92 | 0.33 | A |

| BaO | 0.010 – 30 | 0.061 | A |

| HfO₂ | 0.009 – 10 | 0.046 | A |

| PbO | 0.008 – 10 | 0.015 | A |

*1 The separated calibration curves were established. The accuracies and corrections on the left and right are for the lower and higher concentrations respectively.

*2 The following corrections are applied; A: theoretical alpha correction; L: overlap correction; B: background ratio correction.

Figure 1: Representative calibration curve of Na₂O, Al₂O₃, SiO₂, V₂O₅, Fe₂O₃, NiO, CuO and PbO. White circles are original points and blue squares are corrected points.

Sample preparation

Powder samples, pre-dried at 110°C, were fused at 1050°C – 1150°C, where the weight ratio of sample to flux is 1:20. Since the dilution ratio correction by the Fusion Bead Correction program was applied to the calibration, it is not necessary to precisely weigh analysis samples and flux; the weight of the sample and the flux should be recorded and then be input in the software at measurement. The Fusion Bead Correction program also has LOI/GOI correction, so that it is not necessary to calcine samples or to obtain LOI or GOI content before fusion.

Evaluation analysis

Analysis for evaluation was performed using the ZSX Primus IV with a 4 kW Rh target X-ray tube. The CRM "RAW V06" (cement) was used for the evaluation analysis. To show the reproducibility of making fused beads, three fused beads of this CRM were made and were quantified. To demonstrate the repeatability, one of the beads was run consecutively 10 times.

The analysis results were tabulated in Table 2.

Table 2: Evaluation analysis results. (unit: mass%)

| Compo. | Standard value | Analysis result *1 | Repro.*2 (std. dev.) | Repeat.*3 (std. dev.) |

| Na₂O | 0.68 | 0.633 | 0.016 | 0.025 |

| MgO | 1.7 | 1.62 | 0.020 | 0.022 |

| Al₂O₃ | 8.81 | 8.63 | 0.042 | 0.033 |

| SiO₂ | 30.31 | 30.05 | 0.110 | 0.062 |

| P₂O₅ | 0.19 | 0.184 | 0.0053 | 0.0022 |

| K₂O | 2.1 | 2.35 | 0.019 | 0.010 |

| CaO | 48.24 | 48.13 | 0.106 | 0.039 |

| TiO₂ | 0.469 | 0.427 | 0.0086 | 0.0076 |

| Mn₂O₃ | 0.118 | 0.112 | 0.0032 | 0.0020 |

| Fe₂O₃ | 3.52 | 3.43 | 0.024 | 0.012 |

| ZnO | 0.044 | 0.044 | 0.0004 | 0.0006 |

| SrO | 0.248 | 0.247 | 0.0001 | 0.0086 |

*1 The average of the repeatability test.

*2 Standard deviation of reproducibility test, where three fused beads were made.

*3 Standard deviation of repeatability test, where 10-times consecutive runs were carried out with a single fused bead, one of the three beads used in the reproducibility test.

Conclusion

Rigaku provides Precalibration package "OXIDE-FB-PAK", for analysis of various oxide materials by the fusion method. The calibration and related parameters, such as measurement conditions and correction coefficients, are pre-installed on the system. Users can start the analysis by running the drift correction samples included in the package. This package covers 23 major and minor components with wide concentration ranges and so is applicable to a wide variety of materials, such as rock, mineral, ore, slag, refractory or cement.

The Fusion Bead Correction program, applied to the calibration of OXIDE-FB-PAK, includes LOI/GOI correction and dilution ratio correction. It is not necessary to precisely weigh samples and flux or to calcine samples before analysis.