Application Note EDXRF2000

Scope

The use of Rigaku NEX DE VS EDXRF analyzer is demonstrated for industrial forensics in investigating unknown sample materials.

Background

XRF is an analysis tool used for non-destructive analysis in industrial forensics to identify and resolve manufacturing issues or contamination within the production and distributor processes. Analysis using XRF allows the operator to determine the elemental composition of foreign material in failure analysis and root cause

analysis to optimize quality control and testing procedures.

EDXRF is a fast and simple means of obtaining the elemental composition of samples investigated in industrial forensics. Samples analyzed are often irregularly shaped, small or available in small quantities. Rigaku NEX DE VS EDXRF analyzer is an excellent tool equipped with small spot size measurement, camera image and powerful yet simple-to-use software for the investigation and identification of foreign material.

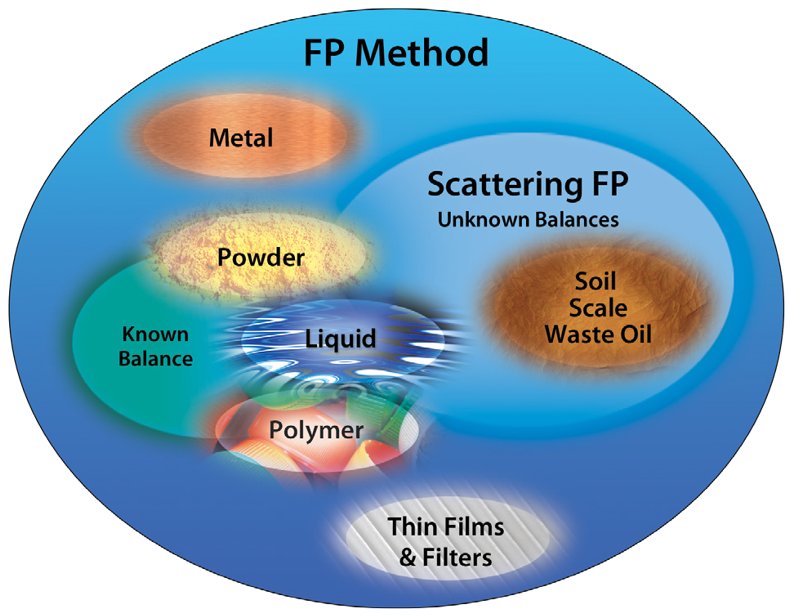

Fundamental parameters (FP)

Industrial forensics involves measuring samples of unknown material and unknown elemental composition. Semi-quantitative analysis (SQX analysis) is employed to analyze samples for forensics examinations using FP (fundamental parameters) methods to calculate concentration results.

Rigaku RPF-SQX Fundamental Parameters (FP) uses an advanced program that automatically deconvolutes spectral peaks and models the sample matrix using fundamental XRF equations, including unique Scattering FP approach for analyzing lighter materials like powders and polymers that have an unknown balance component that cannot be directly measured.

Sample model selection

Rigaku NEX QuantEZ® software includes many application templates for the material categories. Templates include:

- Metals and alloys

- Powders and pellets

- Polymers

- Thin films and filters

- Water, oils and liquids

FP models include bulk analysis, analysis of light materials and thin films, and Rigaku Scattering FP.

Templates can be used as is for general screening while also flexible in design allowing users to change and craft an application to meet specific needs.

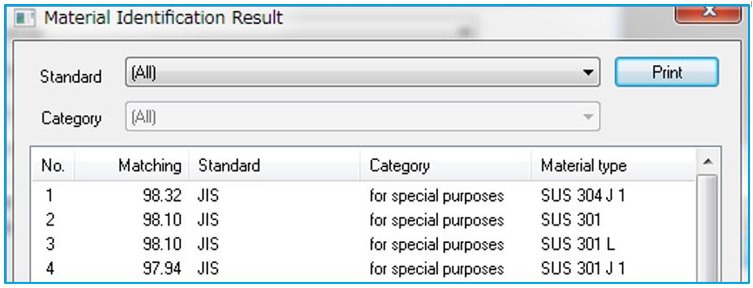

Optional Material Identification software for alloy identification can also be used to identify alloy types of unknown metals and foreign matter using the standard ASTM and JIS tables for ferrous, aluminum, and copper-based alloys. Custom identification tables can also be made by the user.

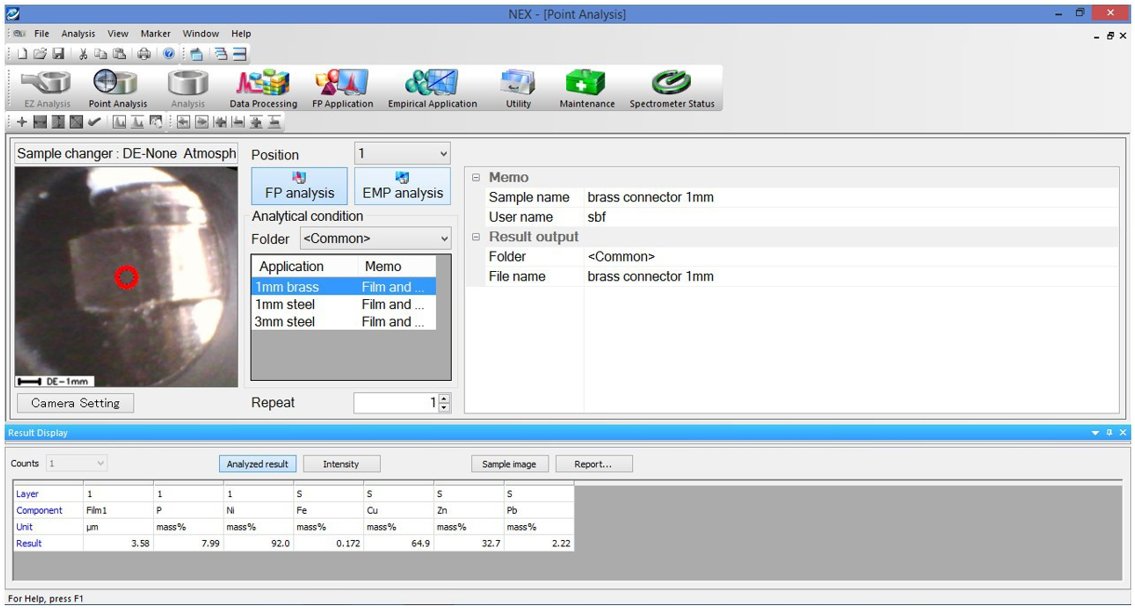

Small spot analysis

Samples that do not completely cover the measurement aperture require small spot size analysis. NEX DE VS is equipped with 10 mm, 3 mm, and 1 mm automatic switching collimators to focus the analysis on the small spot required to be measured.

Examples

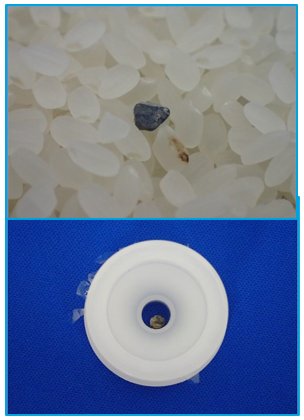

Chip of foreign material in rice

In this example, the foreign matter was found in rice. Analysis was made by placing the sample in a small-spot sample cup.

Measurement results using small spot point analysis indicated elemental composition consistent with a stone or a pebble, information that is helpful in tracing the origin of the source of contamination.

| Component | Content (mass %) |

| SiO₂ | 74.9 |

| CaO | 9.25 |

| Al₂O₃ | 8.80 |

| Fe₂O₃ | 1.35 |

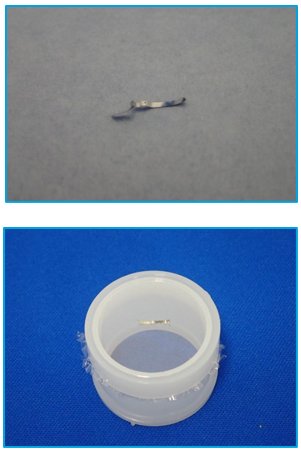

Metal shard foreign material

In this example, a metal shard is examined and prepared using the film sandwich sample cup method and small spot analysis.

Results of the measurement of the shard compared to the surrounding area where it was found indicated a Fe-based metal alloy. Material Identification software verified the shard was a piece of stainless steel, and important clue in foreign matter investigation of a product or failure analysis of machinery.

| Component | Content (mass %) |

| Fe | 71.2 |

| Cr | 16.9 |

| Ni | 6.92 |

| Mn | 2.52 |

Conclusion

Innovative design and simple, intuitive software make the NEX DE VS an ideal EDXRF analyzer for use in industrial forensics. Fundamental Parameter methodology with small spot measurement capability to analyze irregularly shaped samples gives the operator valuable tools in investigating the identification of foreign material of unknown composition.