Application Note EDXRF1720

Scope

The measurement of nickel, phosphorus, and lead electroless nickel plating on various metal substrates is demonstrated.

Background

Electroless Nickel plating (EN) deposits a nickel-phosphorus or nickel-boron coating, providing an even, protective coating on metal or plastic materials for wear, corrosion resistance, or cosmetic enhancement. In the case of phosphorus- nickel plating on a metal (PEN), typically 2 – 14% phosphorus content determines the metallurgical properties of the nickel alloy coating. A stabilizer such as lead is co-deposited with the nickel to slow down the reduction speed. Measurement and control of these elements in the plating bath and deposited coating are important for optimum product quality. To meet this industry need, Applied Rigaku Technologies offers the NEX DE VS benchtop EDXRF system. Easy to operate at-line or in the lab, the NEX DE VS uses a special fundamental parameters application method that automatically calculates the plated coating thickness and composition and measures liquids using simple empirical calibration. NEX DE VS automatic switching collimators also offer small spot measurements down to 1 mm spot size for measuring plating on smaller pieces.

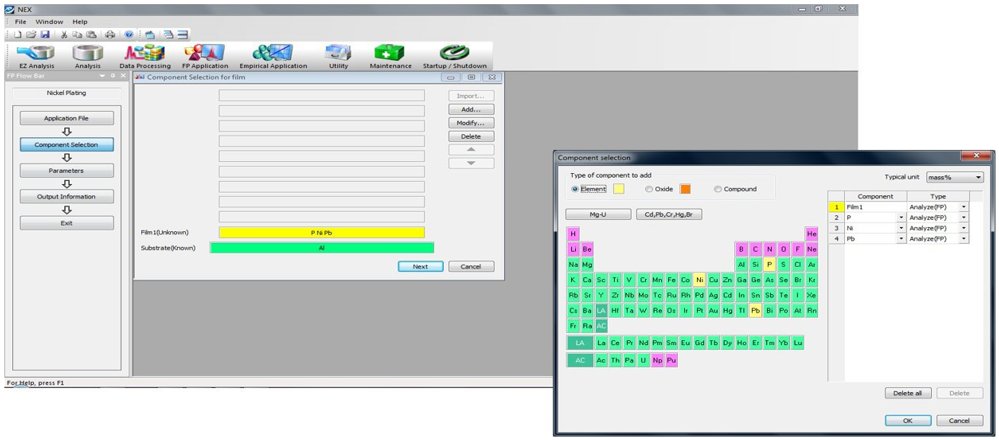

Fundamental parameters (FP)

The Rigaku RPF-SQX Fundamental Parameters (FP) default template for Film and Coatings was utilized to analyze the samples. RPF-SQX uses an advanced program that automatically deconvolutes spectral peaks and models the sample matrix using fundamental XRF equations. The Film and Coatings Template is modified to include substrate type and composition as well as the composition and thickness of the deposited layers. If the precise composition is not known, the user can list the thickness and composition of the layers as unknowns to be solved by the software algorithms.

RPF-SQX analysis results

RPF-SQX analysis results

The analytical method was developed from Rigaku’s RPF-SQX Film and Coating template. The template simultaneously measures both the coating composition and thickness. The measurement results for various samples are shown here.

| Sample ID: Steel Substrate: Fe |

|

| Coating component | Result |

| Coating thickness | 33.6 µm |

| P | 11.30 % |

| Ni | 88.6 % |

| Pb | 0.0449 % |

| Sample ID: Stainless Steel Substrate: Fe, Cr, Mo |

|

| Coating component | Result |

| Coating thickness | 35.5 µm |

| P | 9.82 % |

| Ni | 90.1 % |

| Pb | 0.0493 % |

| Sample ID: Hard Disk Drive Substrate: Al |

|

| Coating component | Result |

| Coating thickness | 13.0 µm |

| P | 12.30 % |

| Ni | 87.7 % |

| Pb | 0.0274 % |

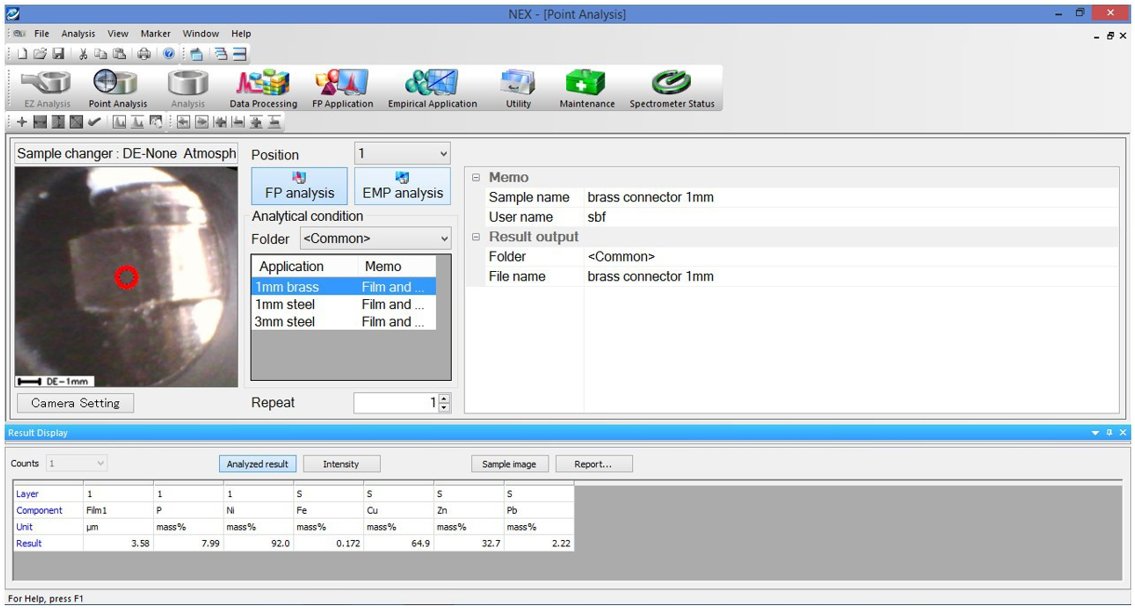

Small spot analysis

NEX DE VS using Camera View and automatic collimators, is ideally equipped to measure smaller parts. Application methods are easily made using 10 mm, 3 mm, or 1 mm analysis spot size. The Point Analysis screen is used to position and measure the sample and see results after analysis.

Typical tubing connectors with electroless PEN nickel coating.

Typical tubing connectors with electroless PEN nickel coating.

A phosphorus-nickel PEN plating is measured on a tubing connector made of brass using the 1 mm collimator.

A phosphorus-nickel PEN plating is measured on a tubing connector made of brass using the 1 mm collimator.

Discussion

Sample analysis was performed using RPF-SQX Film and Coating Template, the template for multi-layer coating on a substrate. The RPF-SQX method uses an advanced FP program that automatically deconvolutes spectral peaks and models the sample matrix using fundamental XRF equations and can resolve thickness and film composition simultaneously.

Analytical accuracy and the FP model can be further optimized using an FP Matching Library. A Matching Library is easily built by the operator. It is used in conjunction with the standard FP library in modeling the sample matrix and calculating concentration and thickness results. One or more known assayed standards are analyzed, and the intensities are registered. The operator simply sets up the registration and inputs the known concentration values.

XRF measures solids, powders, thin films, and liquids. NEX DE VS is also an excellent tool for measuring the plating bath directly in liquid form. To analyze the plating bath, approximately 5 ml of the plating liquid is placed in a 32 mm diameter XRF sample cup and measured directly, without damaging or changing the sample in any way.

Conclusion

Innovative design using a 60 kV tube and high-resolution detector with 500,000+ cps throughout provides sensitivity for trace measurements and low detection limits. Simple, intuitive software flow makes the NEX DE VS an ideal EDXRF tool for the elemental identification, screening, and characterization of coatings. Plating baths as liquids can also be measured to ensure optimum bath control. Simple to operate, the NEX DE VS is easily mastered by the non-technical operator and researcher alike.