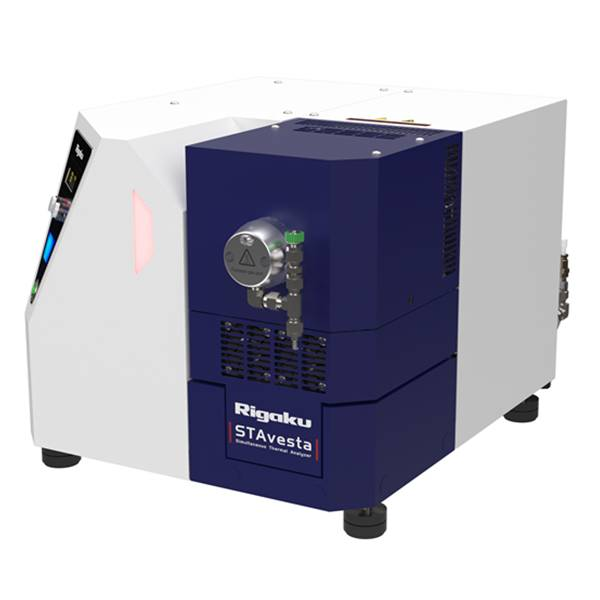

STAvesta

Thermogravimetric-Differential Scanning Calorimeter (TG-DSC)

Measurement of mass changes and endothermic/exothermic reactions

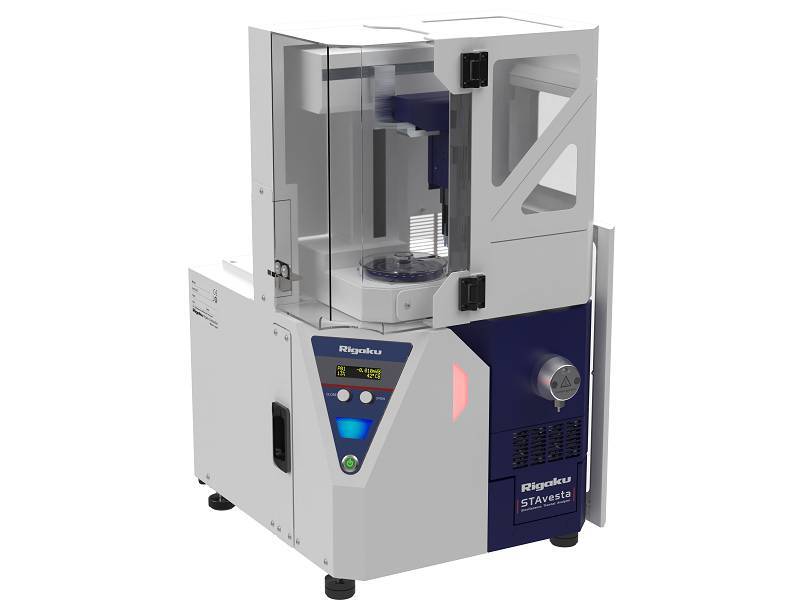

STAvesta is a next-generation simultaneous TG-DSC system that brings together the essential features every thermal analysis user needs—powerful functionality, outstanding precision, and dependable stability—in one compact and versatile instrument.

Key innovations—such as reduced residual oxygen concentration, a newly developed auto-adjusting baseline feature, and uniform furnace temperature distribution—contribute to high-quality, reproducible quantitative data across repeated measurements. Together, these advancements deliver measurement performance that users can trust.

With six types of easily interchangeable electric furnaces—including a sample observation furnace with real-time camera monitoring, a refrigerated cooling furnace, and a high-concentrate water vapor furnace—STAvesta can be expanded to integrate with gas analysis systems such as GC-MS and FTIR.

From new users seeking intuitive operation to seasoned experts requiring advanced functionality, STAvesta is a robust, forward-thinking solution that evolves with your analysis needs.

STAvesta Overview

Precision made simple – Advanced STA performance with confidence

With six types of easily interchangeable electric furnaces, STAvesta allows you to switch measurement targets or analysis methods with minimal effort. Furnace exchange is quick and simple, and there's no need to remove other attachments; a user-friendly design detail that saves time and effort.

STAvesta can be expanded to integrate with gas analysis systems such as GC-MS and FTIR, enabling hyphenated measurements that provide deeper insight into complex thermal reactions.

Highly accurate triple-coil balance for reliable baseline correction

The twin-holder differential TG-DSC system employs a horizontal differential triple-coil balance. This configuration effectively cancels out sources of drift, ensuring consistently accurate weight-change measurements with ease.

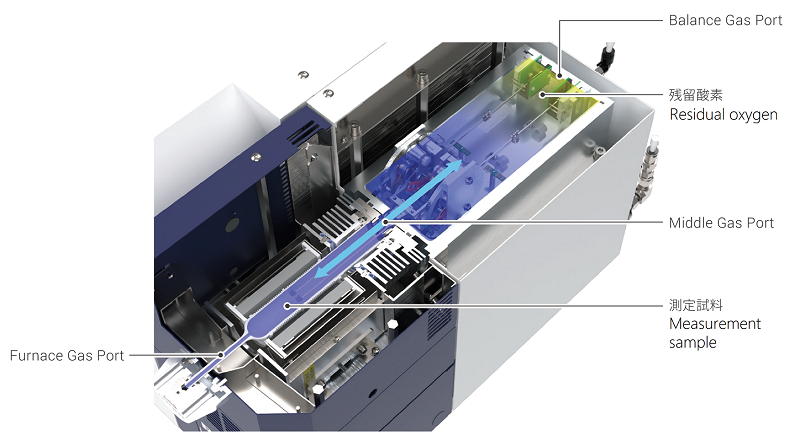

Sealed, optimized balance chamber for improved atmosphere control

STAvesta features enhanced system sealing and optimized gas flow design. Gas introduced from the middle gas port is divided between the furnace and the balance chamber, preventing residual oxygen accumulating in the balance area from reaching the sample.

This enables rapid reduction of oxygen concentration near the sample with minimal gas consumption.

Stable, worry-free measurement with enhanced reproducibility

The horizontal differential balance offers TG baseline reproducibility better than 10 μg. Combined with our innovative FlatBlank function, which automatically adjusts the blank signal, STAvesta allows for more stable and reproducible thermal measurements even under low-gas conditions.

→see more about the FlatBlank function

Even temperature distribution with isothermal unit

By integrating an isothermal unit within the furnace’s protective tube, the temperature around the sample is uniformly distributed. This minimizes the effects of radiation and convection, resulting in a significantly more stable DSC baseline and allowing for highly accurate and reliable quantitative analysis.

(Compatible with: standard furnace (S), high temperature furnace (H), and indirect heated furnace (B))

Advanced temperature control system for better hold accuracy

The STAvesta is equipped with both Rapid Control and Advanced Control as standard, ensuring precise temperature following during isothermal or slow heating rate measurements.

→see more about Rapid Control + Advanced Control

Flexible measurement systems for varied applications

Designed to meet diverse analysis needs, STAvesta supports dynamic TG (compatible with CRC and SIA methods) for improved resolution and separation. The system is expandable to STA/GC-MS for identifying evolved gases, and available with the ASC autosampler for high-throughput automated sample exchange.

Versatile furnace options for a range of conditions

All seven types of Rigaku furnaces—Standard, High temperature, Sample Observation, Indirect Heated, HUM (humid atmosphere), and Refrigerated Cooling (down to -40 °C)—are easily interchangeable by the user. This adaptability allows a single STAvesta unit to support a wide range of analyses, eliminating the need for multiple dedicated systems.

Built-in self-diagnostic system – vestaeye

Before starting a measurement, the system runs a self-diagnosis to check for abnormalities. Full diagnostics are performed on startup, and quick checks during standby or measurement ensure safe and reliable daily operation.

At-a-glance instrument status display

A uniquely designed LCD panel located on the front right corner displays essential information such as current temperature and TG/DSC signals, offering a clear view of system status. In case of an error, an error code is shown to help quickly identify the issue.

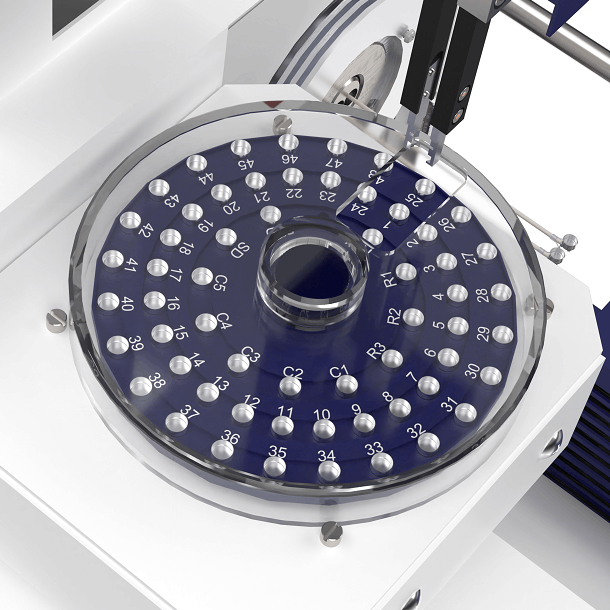

Optional ASC (Auto Sample Changer) for greater throughput

Upgradeable with ASC for automated measurements

The optional ASC can be added later and holds up to 52 samples. It enables uninterrupted, high-throughput measurements—up to 1,000 continuous runs—by automatically replacing samples. The transport speed has more than doubled compared to previous models, improving automation and efficiency. It also supports reference pan replacement and auto-calibration functions to further minimize downtime.

A gas flow system around the sample tray reduces ambient exposure, supporting accurate measurements of moisture-sensitive powder samples.

No need for special pans

Standard sample pans can be used—no dedicated ASC pans required.

Quick manual override when needed

A dedicated window for single-sample analysis allows quick, flexible measurements even in the middle of an automated run. Emergency samples can be prioritized using interrupt mode.

Automated reference pan exchange

Up to three types of reference pans can be loaded. The ASC automatically selects a suitable reference pan for each sample pan type (e.g., aluminum, alumina, platinum), enabling accurate measurement across a variety of sample materials.

STAvesta Features

STAvesta Specifications

| Model name | Thermo plus EVO3 STAvesta Simultaneous Thermal Analyzer |

|

|---|---|---|

| Technology | Thermogravimetry-Differential Scanning Calorimeter (TG-DSC) | |

| Measurement temperature range | Standard: Room temperature to 1,100°C High temperature: Room temperature to 1,500°C Indirect heated: Room temperature to 1,500°C Sample observation: Room temperature to 1,100°C *¹ HUM: Room temperature to 1,400°C Refrigerated cooling: -40 to 700°C |

|

| Heating rage(max) | Standard: 100°C/min High temperature: 100°C/min Indirect heated: 50°C/min Sample observation: 100°C/min HUM: 20°C/min Refrigerated cooling: 20°C/min |

|

| Sample amount (max) | 1g (90 μL) | |

| TG range | ± 500 mg | |

| DSC rage | ± 600 mW (100°C) ± 1,400 mW (1,000°C) ± 3,000 mW (1,500°C) |

|

| DTA range | ± 1,000 μV | |

| Specific heat precision*² *³ | ± 3% | |

| TG baseline drift volume*² | <10 μg (up to 1,000°C), <20 μg (up to 1,400°C) | |

| Measurement atmosphere | Standard (S): Air, inert gas, under reduced pressure*⁴ High temperature (H): Air, inert gas, under reduced pressure*⁴ Indirect heated (B): Air, inert gas, under reduced pressure*⁴ Sample observation (C): Air, inert gas, under reduced pressure*⁴ Refrigerated cooling (LR): Dry gas (Simulated air, inert gas N2, Ar, He) HUM: Inert gas (N2), humidity atmosphere |

|

| Options | Automatic sample changer (Sample: 52, reference: 3, calibration sample: 5) Furnace unit (Standard, high temperature, indirect heated, sample observation, HUM, refrigerated cooling) ASC safety cover Isothermal unit (compatible furnace: S, H, B) Evolved gas introduction interface |

|

| Dimensions | Furnace type: standard (S), high temperature (H), indirect heated (B) 412(W) x 355(H) x 561(D)(mm) 412(W) x 705(H) x 561(D)(mm) (with ASC) |

|

| Mass | 45 kg 55 kg (with ASC), 61 kg (with ASC and safety cover) |

|

| Power requirements | 1Ø, AC100-120 V/200-240 V, 50/60 Hz, 15 A | |

| *1 For sample observation measurement: up to1,000°C *2 Under Rigaku measurement condition *3 compatible furnace: standard and high temperature *4 Not compatible with ASC measurement |

||

STAvesta Options

The following accessories are available for this product:

ASC for STAvesta

Optional ASC (Auto Sample Changer) for greater throughput Upgradeable with ASC for automated measurements

STAvesta ASC Safety cover

The ASC safety cover is designed to reduce mechanical hazards associated with the automatic sample changer (ASC).

Isothermal Unit

By incorporating an isothermal unit inside the protection tube, the heat distribution around the sample is made more uniform.

Sample Pan

Depending on the sample to be measured (especially if the sample is metal), it may melt the sample pan and damage the sample holder or other parts of the instrument.

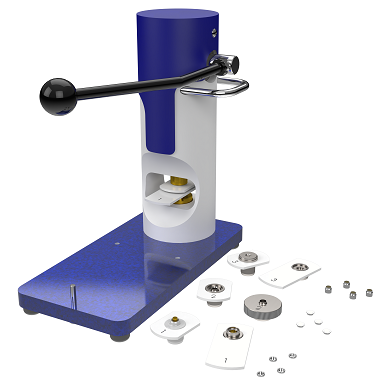

Sample sealer / Sample crimper

A sample pan shaping tool with three functions: sample crimper, sample sealer, and high-pressure sample sealer.

Flow Meter

The flow meter controls the flow rate of the atmospheric gas (inert gas, air, etc.) supplied to the sample chamber.

Gas Selector

Links to the measurement program and switches the gases flowing into the sample chamber.

2ch-FLOW COMPO Jr.

Enables gas flow, flow rate setting and switching of gases with precision specified in the measurement program. Gas types and full scale can be selected.

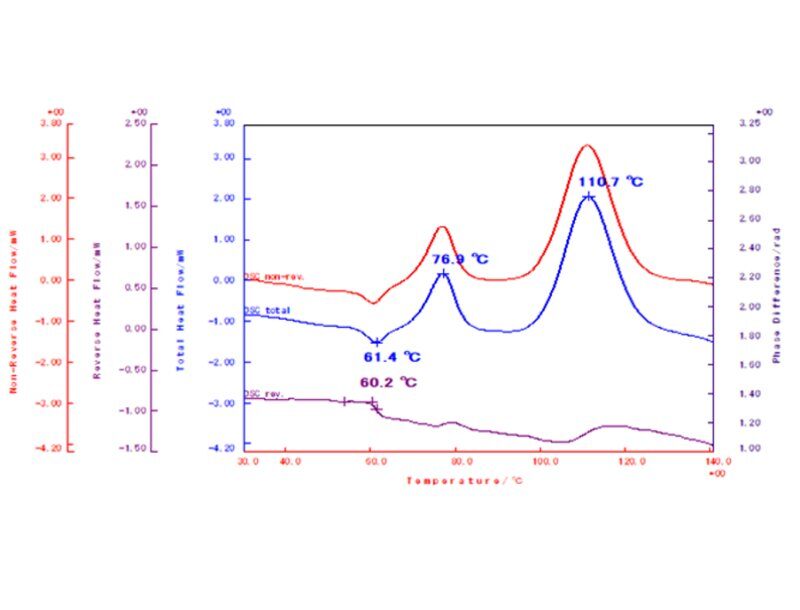

Dynamic DSC

This technique allows for the separation of overlapping reactions and facilitates the straightforward determination of specific heat capacity.

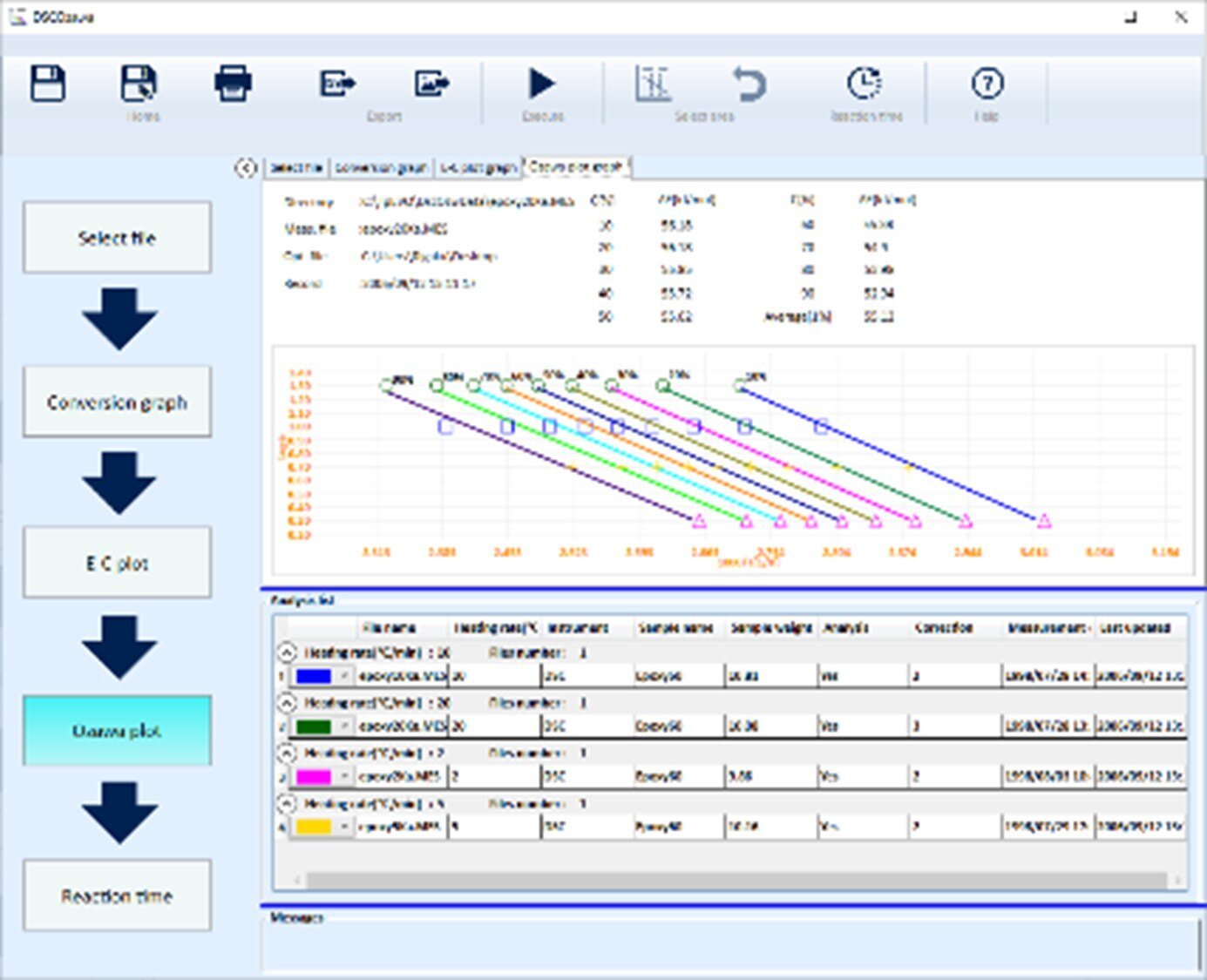

DSC Ozawa method/TG Ozawa method

In this method, the activation energy can be estimated from more than three measurements with different heating rates, estimating the time to reach a defined degree of conversion.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.