Application Note B-TA1048

Introduction

The crystalline morphology of polymers changes depending on the cooling rate after melting, and different melting peaks may appear depending on the cooling conditions. LLDPE (linear low-density polyethylene) was crystallized under three cooling conditions—5 °C/min, 2 °C/min, and step cooling—and the resulting melting peaks during the subsequent heating process were compared.

Step cooling: 123 °C, 93 °C, and 63 °C, each held for 10 minutes.

Measurement and analysis example

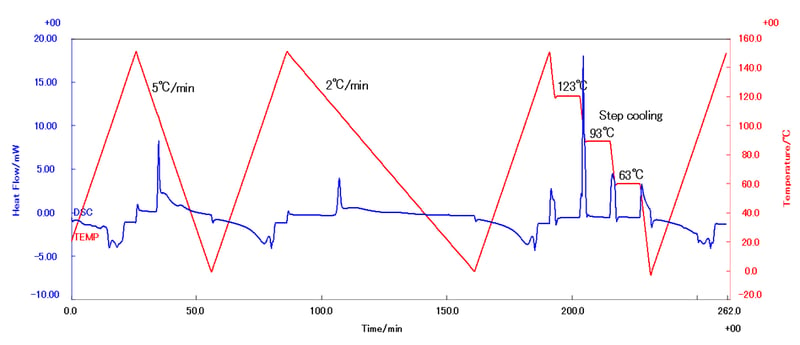

Figure 1 shows the DSC results of LLDPE. During the heating process, endothermic peaks due to melting are observed between 40 °C and 130 °C, while during the cooling process, exothermic peaks associated with crystallization are observed.

Figure 1: Cyclic DSC measurement by heating and cooling

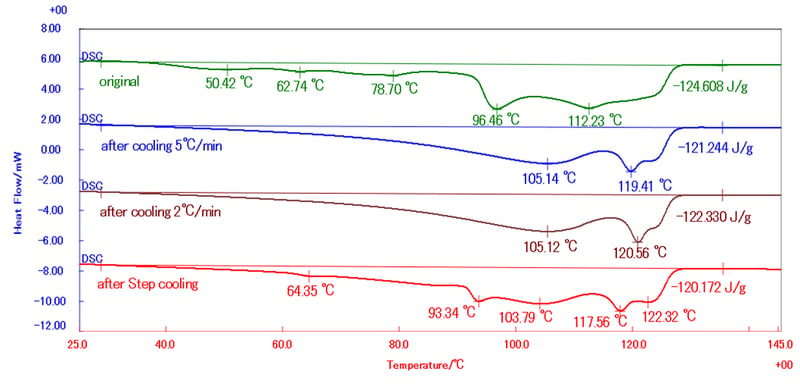

Figure 2 shows the overlaid melting peaks extracted from the heating process under different cooling conditions.

Figure 2: Melting behavior of crystallized samples under different cooling conditions

Under the cooling conditions of 5 °C/min and 2 °C/min, similar melting peaks behavior was observed, suggesting that similar crystalline structures were formed.

In addition, when compared with the melting peak behavior of the initial (original) sample with that of the samples at different cooling rates, a clear difference is observed, suggesting that the cooling conditions during the manufacturing process of the original sample were different.

The melting peak behavior obtained after the step‑cooling conditions (123 °C, 93 °C, and 63 °C with a 10‑min hold at each temperature) shows a somewhat similar shape to that of the original sample, suggesting that the cooling conditions during the manufacturing process of the original sample were relatively close to those of the step‑cooling procedure.

Thus, the melting peak behavior reflects the crystallization induced by the cooling conditions during manufacturing, and by comparing the melting peaks, it is possible to evaluate differences in cooling conditions (thermal history) within the manufacturing process.

Recommended equipment and software

► Thermo plus EVO3 DSCvesta2 + Refrigerated cooling unit

► Vullios measurement and analysis software