Application Note RACCT9048

Introduction

Additive manufacturing, commonly known as 3D printing, is increasingly popular due to its ability to produce complex shapes without geometric constraints. It enables quick and adaptable prototyping while allowing the utilization of a diverse array of materials.

As capabilities grow, so do the complexities and challenges in product design. Therefore, it is essential to use advanced characterization techniques that offer comprehensive evaluations of manufactured products and help optimize the design and process parameters.

X-ray Computed Tomography (CT) is a versatile, non-destructive, 3D volume imaging tool for structural inspection. It can accommodate a wide range of sample sizes at different stages of additive manufacturing. With scan times as short as tens of seconds, CT generates a detailed digital replica of the product, enabling both quantitative analysis of the internal defects and dimensions and property simulation.

About the sample: superalloy car sample

This experiment demonstrates the application of X-ray CT to inspect the internal structure of a superalloy (Inconel®) car sample at the final product stage, produced via powder bed fusion by Nissin Manufacturing Co. Ltd.

Analysis procedure

- In this example, a 3D-printed superalloy sample was scanned using a micro-CT scanner, the CT Lab HV, to measure structural information non-destructively.

- The 3D volume of the 3D printed car sample was segmented with manual histogram thresholding for structural analysis.

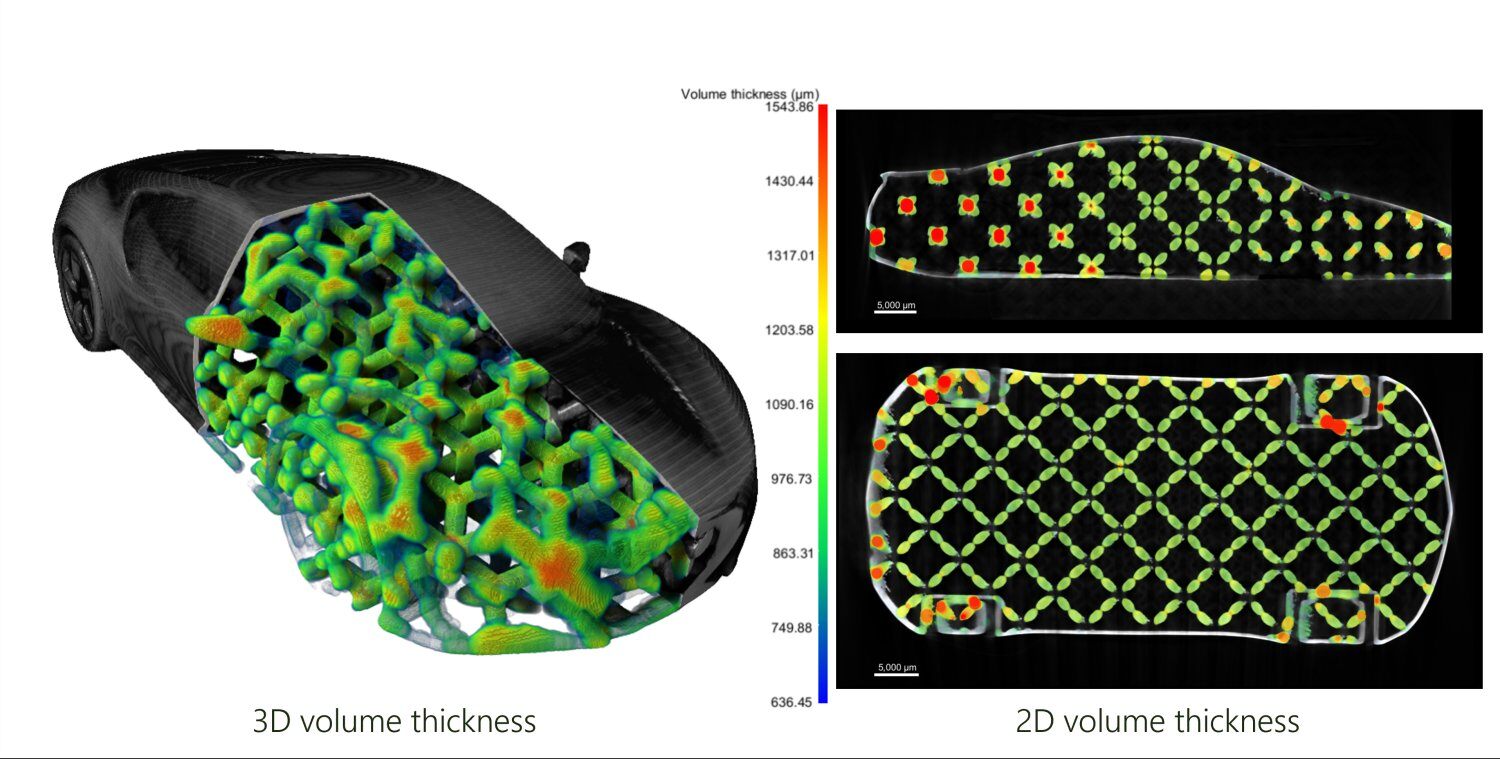

- The volume thickness of the internal lattice structure was calculated and visualized to analyze internal feature integrity.

- A load simulation was performed to show the maximum principal stress distribution.

CT scan

Imaging high-density, heavy materials like the Inconel superalloy used in this 3D-printed car sample requires higher X-ray energy to minimize beam hardening artifacts. To achieve this, the sample was scanned with 200 kV, 70 µA using the CT Lab HV, a high-voltage CT system capable of generating X-rays with acceleration voltage up to 225 kV.

A 3D view of the sample exterior, as well as a section of the internal structure revealed through transparency, is shown below. The internal structure was revealed to consist of diagonally patterned grid-like support, as seen in both the 3D rendered and 2D cross-sectional views.

The edge and the corner of the grid-like structure show irregular bumps on the surface, as highlighted with arrows in the figure below. These irregularities might be residual agglomerated metal powder left on the untreated surface after the powder fusion process.

Volume thickness analysis

Because the data had very good grayscale contrast, segmentation was performed using simple histogram thresholding on the CT data to highlight solid structure. Visualization and quantification of the grid-like support structure inside the sample were then performed with Dragonfly 3D World.

The video shows 3D visualization and quantitative analysis for external and internal features of interest, and volume thickness distribution of the internal grid structure.

Load simulation

A surface mesh of the 3D-printed car sample was created for load simulation using VGStudio MAX. A force of 150 kN was applied evenly across the roof section of the superalloy car sample, simulating downward compression. The resulting distribution of maximum principal stress is shown in the figure below in 3D and 2D views. In the visualization, red areas represent regions of high tensile stress, while blue areas indicate higher compression stress. If the stress in high-stress areas exceeds the material’s modulus, permanent deformation is likely to occur in those regions, potentially causing damage or fractures in the car sample.

Conclusions

This study highlights the efficacy of X-ray CT imaging for evaluating advanced manufacturing processes. Using the CT Lab HV, internal and external structures of a 3D-printed Inconel car sample were examined non-destructively, providing critical insights into structural integrity and manufacturing quality. Analysis such as volume thickness and load simulations revealed internal structure consistency and potential weak points. These findings demonstrate the benefits of integrating advanced 3D imaging to optimize design, manufacturing, and conducting performance evaluation of complex components in industries that demand precision engineering.