Application Note EDXRF1108

Scope

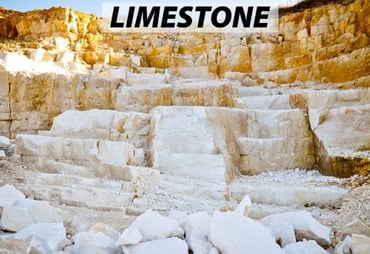

The analysis of limestone is demonstrated using the empirical approach.

Background

Limestone has historically been used as a major material in the construction of buildings and monuments, as well as the production of glass. More modern uses of limestone include as a raw material in the production of quicklime, cement and mortar, as well as a basic aggregate in road construction. Limestone is also used as a scrubber stone in the desulfurization of flue gas and is used as a reagent in blast furnaces to extract iron from ore. Purified, limestone has many uses as a calcium supplement in foods and animal feeds, and well as a whitener in cosmetics. The high calcium content of limestone is also an ideal ingredient in remineralization and can be used in water, toothpaste, mouth rinses, etc. Because of the wide variety of uses for limestone, quality control and precise characterization is an important part of limestone mining and processing operations.

Limestone has historically been used as a major material in the construction of buildings and monuments, as well as the production of glass. More modern uses of limestone include as a raw material in the production of quicklime, cement and mortar, as well as a basic aggregate in road construction. Limestone is also used as a scrubber stone in the desulfurization of flue gas and is used as a reagent in blast furnaces to extract iron from ore. Purified, limestone has many uses as a calcium supplement in foods and animal feeds, and well as a whitener in cosmetics. The high calcium content of limestone is also an ideal ingredient in remineralization and can be used in water, toothpaste, mouth rinses, etc. Because of the wide variety of uses for limestone, quality control and precise characterization is an important part of limestone mining and processing operations.

Model: NEX CG

Model: NEX CG

Calibration

Empirical calibrations were built using a set of 8 assayed standards, including NIST SRM 1d (Limestone, Argillaceous). The standards are representative of the limestone ores at the mine site. Using the empirical approach, “alpha corrections” are then employed to compensate for variations in X-ray absorption and enhancement effects within the sample due to the independent variations in element concentration, thus yielding a very accurate model characterizing the ore type. A summary of each empirical calibration is shown here.

| Component | Concentration range (%) |

| MgCO₃ | 0.53 – 8.66 |

| Al₂O₃ | 0.19 – 2.35 |

| SiO₂ | 0.95 – 8.67 |

| CaCO₃ | 84.95 – 95.12 |

| Fe₂O₃ | 0.12 – 0.86 |

Repeatabilty

To demonstrate repeatability (precision), one representative sample was chosen from the set of calibration standards. Each sample was measured in static position for ten repeat analyses with typical results shown below.

Sample: NIST SRM 1d

| Component | Assay value (%) | NEX CG average result | Standard deviation | % Relative |

| MgCO₃ | 0.63 | 0.64 | 0.047 | 7.5 |

| Al₂O₃ | 0.526 | 0.535 | 0.010 | 1.9 |

| SiO₂ | 4.08 | 3.99 | 0.035 | 0.9 |

| CaCO₃ | 94.32 | 94.57 | 0.23 | 0.2 |

| Fe₂O₃ | 0.136 | 0.138 | 0.002 | 1.5 |

Sample: Quarry Sample 7A

| Component | Assay value (%) | NEX CG average result | Standard deviation | % Relative |

| MgCO₃ | 1.64 | 1.69 | 0.022 | 1.3 |

| Al₂O₃ | 0.29 | 0.26 | 0.004 | 1.4 |

| SiO₂ | 2.58 | 2.50 | 0.020 | 0.8 |

| CaCO₃ | 95.12 | 95.32 | 0.19 | 0.2 |

| Fe₂O₃ | 0.120 | 0.127 | 0.002 | 1.7 |

Discussion

A typical approach for creating the most accurate empirical calibrations is to develop the set of calibrations from actual quarry samples. To improve the model of the matrix and to allow for changes in limestone composition, the initial calibrations can be expanded and augmented using addition assayed samples.

Sodium is rarely monitored in limestone, typically only for a few specialty limestone products. The samples measured for this App Note did not contain Na.

Conclusion

The Rigaku NEX CG combines indirect excitation with secondary targets, polarization targets and a high performance SDD detector to yield the optimum performance for elemental analysis of limestone. During the entire quarrying and processing cycle, oxide composition of the limestone material must be reliably monitored to ensure optimal process control and profitability. The Rigaku NEX CG analyzer is an ideal tool throughout the quality control process. In addition, the NEX CG can be used to monitor air filters for air quality emission control, and UltraCarry can be used to monitor process effluents to ppb range detection limits, making the NEX CG a versatile and valuable tool for several applications within limestone mining and processing.