Decoding Defects: Failure Analysis Using X-ray CT

4. Non-Destructive Inspection of Batteries Using X-ray Computed Tomography

This is a written summary of a live webinar presented on August 21, 2024. The recording and resources are available on the recording page.

Presented by:

Webinar summary

The webinar, part of a series focused on X-ray analysis of battery materials, offers a comprehensive and technically detailed overview of how X-ray CT can be applied to battery research across scales, from entire battery cells to raw electrode materials. The primary focus is on using this non-destructive technique to gather both qualitative and quantitative data that directly inform battery performance, design, and failure mechanisms.

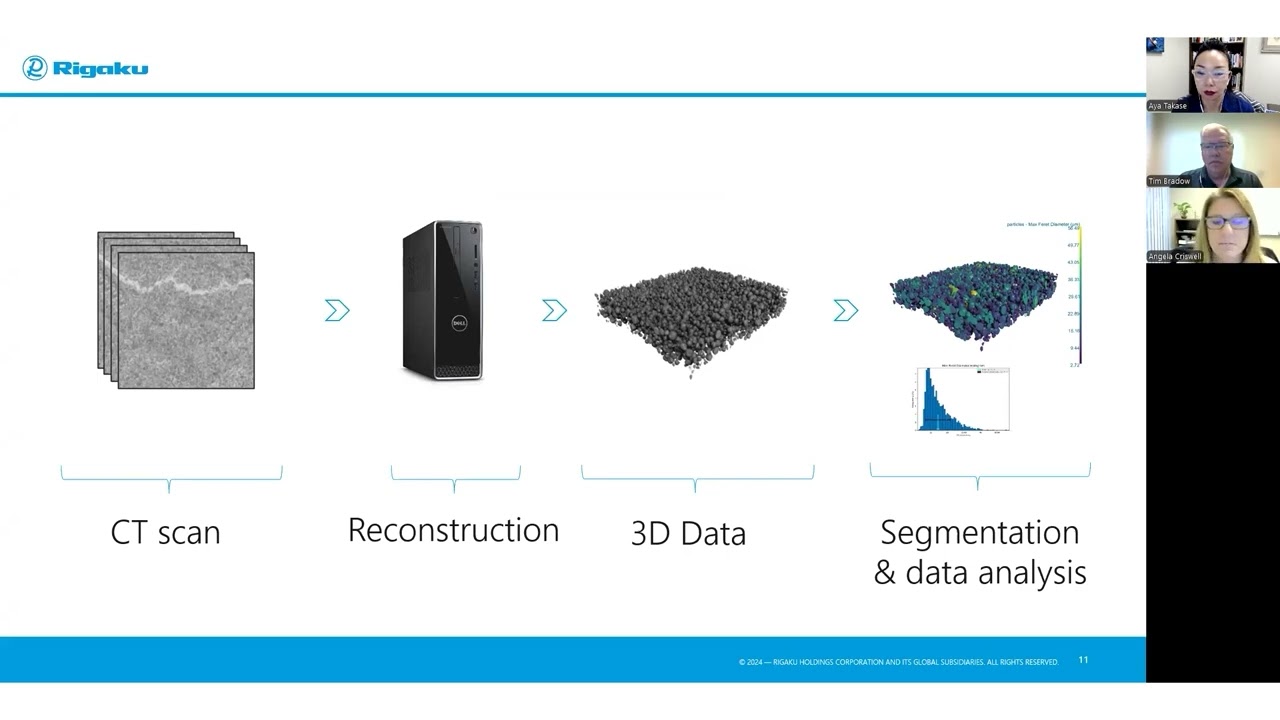

Angela begins by laying out the complexity of battery systems, highlighting that they span a wide range of length scales—from large battery packs with millimeter-scale features to nanometer-scale particles in electrodes. This scale variance demands careful selection of CT instruments and settings, as no single system can optimally image all battery components. She explains how X-ray CT works: X-rays are projected through a rotating sample, and the transmitted photons are collected as 2D projection images. These are then reconstructed into a 3D volume—the "digital twin" of the sample—which can be segmented to identify different material phases for further analysis.

The session goes in-depth into the physical principles underpinning image contrast and resolution. X-ray energy is a key variable: lower-energy radiation (e.g., from copper targets) enhances contrast for low-density materials like separators or anodes, while higher-energy beams (e.g., from tungsten) are better suited for dense or thick materials like cathodes and whole cells. Angela provides illustrative examples showing how inappropriate energy selection can obscure internal features and how higher voltages improve penetration and detail visibility in thicker samples like 18650 cells.

Another major consideration is spatial resolution, which is tightly coupled with field of view. While smaller voxel sizes offer finer resolution, they drastically increase data file size, sometimes to impractical levels (e.g., terabytes for imaging an entire cell at submicron resolution). The solution is a hierarchical approach: image the full battery at low resolution, identify regions of interest, and then zoom in for higher-resolution scans. Angela reinforces the importance of matching voxel size to feature size—ideally one-fifth or less of the smallest feature of interest—to ensure accurate measurement of parameters like porosity or fiber diameter.

The presentation also addresses signal-to-noise optimization. Techniques include longer exposure times, reducing air gap between source and detector, and binning pixels—though the latter trades resolution for signal strength. Angela shares practical tips and points to additional resources like blog posts for deeper technical guidance.

A particularly important part of the webinar discusses experimental types: ex situ (isolated components), in situ (entire battery mounted and reimaged between cycling), and operando (imaging during charge/discharge). Each provides different insights, with operando offering the most dynamic view of structural evolution.

The practical value of X-ray CT is demonstrated with a series of compelling examples. Angela shows how full-cell scans reveal defects like electrode warping or delamination, which can cause performance degradation or even failure, as illustrated with a degraded camera battery. She uses segmentation tools like VG Studio Max and Dragonfly, including deep learning modules, to isolate phases and measure features like electrode curvature, delaminated volume, and overhangs—critical parameters for assessing manufacturing quality and failure modes.

Zooming into smaller scales, she examines cathode particles in a 3 mm pouch cell, using characteristic molybdenum radiation and submicron voxels. Analysis of particle size distribution, porosity, and shape reveals structural irregularities—some particles are even cracked despite the battery being pristine. She applies watershed algorithms for particle separation and tracks changes in size and morphology, which can be correlated with battery performance and aging.

She also explores separator layers using copper radiation for better fiber contrast, analyzing fiber thickness, porosity, and packing density. These characteristics are essential for ensuring ionic transport while maintaining mechanical stability. The discussion briefly touches on anode material imaging, noting that copper radiation is better suited but was not used in her current dataset.

The webinar closes with an advanced example from Osaka Prefecture University on solid-state lithium metal batteries. This in situ study tracks crack formation over charge/discharge cycles. X-ray CT reveals internal fracture patterns that correlate with chemical changes, specifically lithium clustering, offering insights into failure mechanisms. Angela emphasizes that such 4D (time-resolved) CT scans are not only possible but increasingly valuable for tracking battery aging and stress evolution. She also confirms that once trained, deep learning segmentation models can be applied across time-series or condition-varied datasets—provided histogram normalization and consistent voxel sizes are used.

This webinar is a valuable resource for battery researchers aiming to integrate high-resolution, non-destructive imaging into their workflows. It not only demystifies the use of X-ray CT but also equips researchers with the practical knowledge needed to design meaningful experiments and extract actionable data from complex battery systems.

Key questions answered in the webinar

-

X-ray CT is a non-destructive inspection technique that uses X-rays to create a 3D digital representation of an object. The process involves an X-ray source, a detector, and the sample placed in between. X-ray photons are directed at the sample; some are absorbed, and others are transmitted through and measured by the detector. During the experiment, the sample is rotated, and hundreds to thousands of 2D projection images are captured at different angles (e.g., 180° or 360° rotation). These 2D images are then fed into a reconstruction program to generate a 3D volume, acting as a "digital twin" of the original sample. This 3D volume can then be analyzed, often involving a process called "segmentation," where different material phases (e.g., particles, air) are assigned unique "voxels" (3D pixels) to allow for quantitative analysis. X-ray CT is an absorption technique, meaning the amount of X-rays absorbed by the sample depends on its density, thickness, and the chosen X-ray energy.

-

Several factors need to be carefully considered for effective X-ray CT analysis of batteries:

- X-ray energy and image contrast: The choice of X-ray energy (either bremsstrahlung or characteristic radiation) significantly influences the image contrast. Higher X-ray energies (higher kV) are generally better for larger and denser samples like full battery cells (e.g., 18650 batteries), as they result in less absorption and better visibility of internal features. Lower X-ray energies, like those produced by copper or molybdenum targets, are more suitable for imaging smaller, lower-density samples such as raw battery materials (e.g., cathode or separator materials), as they provide higher absorption and contrast for these delicate structures.

- Spatial resolution and field of view: Spatial resolution, determined by the "voxel" size, dictates the smallest features that can be resolved. A general rule of thumb is that the optimal voxel size should be 1/5 or smaller than the smallest feature being imaged. However, there's a trade-off with the field of view: smaller voxels (higher resolution) result in a smaller field of view and significantly larger file sizes, which can be computationally challenging. A common strategy is to first collect a low-resolution scan of the entire sample to identify regions of interest, and then zoom in to collect higher-resolution data on those specific areas.

- Signal-to-noise ratio (SNR): Sufficient SNR is crucial for accurate data analysis and segmentation. Lower SNR leads to grainy images and unclear feature boundaries, making quantitative analysis difficult. Ways to improve SNR include increasing scan time, shortening the source-to-detector distance (to reduce X-ray absorption by air), and binning pixels (though this reduces resolution).

- Experiment type: The chosen experiment type depends on the research goal. "Ex situ" experiments involve imaging isolated battery materials. "In situ" experiments involve imaging intact battery cells, often repeatedly after charge/discharge cycles. "Operando" experiments take this a step further by collecting data during charge and discharge cycles, requiring very fast scan times.

-

X-ray CT provides both qualitative and quantitative insights into battery performance and degradation. It allows researchers and manufacturers to understand structural changes that directly impact battery efficiency and lifespan.

At the micrometer to nanometer scale (e.g., electrode materials):

- Quantitative: Porosity, particle size distribution, particle sphericity/shape (length-width measurements), permeability, path of lithium ions, tortuosity, and surface area.

- Qualitative: Anode and cathode designs, separator design, electrolyte distribution, and the behavior of electrodes and internal materials in small battery cells.

At the micron to meter scale (e.g., whole battery):

- Quantitative: Angular deflection of electrodes, electrode thickness, void porosity, delamination volume and thickness, and uniformity.

- Qualitative: Detection of deflected electrodes (e.g., from manufacturing defects or swelling), burrs, internal impurities, and changes in casing due to venting mechanisms.

Ultimately, this data helps link performance loss (e.g., capacity reduction) to structural changes like deformation, delamination, and crack formation. Qualitative information about failure analysis can be extracted from the data.

-

There are three main approaches to examining battery function with X-ray CT:

- Ex situ experiments: These involve imaging isolated or raw battery materials, such as an electrode layer, outside of a complete battery cell. This is useful for initial characterization of materials.

- In situ experiments: In this approach, an intact battery cell is mounted on the instrument, imaged, then removed for charge/discharge cycles, and subsequently re-imaged. This allows researchers to observe structural changes that occur after specific usage patterns without disassembling the battery.

- Operando experiments: This is the most dynamic type, where data is collected while the battery undergoes charge and discharge cycles. This provides real-time insights into the structural evolution during operation. However, it requires very fast scan times, as the scan must be faster than the process being studied.

-

X-ray CT is a powerful tool for battery failure analysis by revealing internal structural defects and degradations that lead to performance loss. For instance, in a damaged battery that no longer holds a charge, CT scans can show significant warping and delamination of electrode layers. These "dead zones" prevent the efficient migration of lithium ions, directly impacting the battery's capacity. CT allows for quantification of such defects, like the volume and thickness of delamination, helping to pinpoint the root causes of failure. An example includes identifying deflected anodes as a potential cause for fires in Samsung Galaxy phones. Furthermore, operando experiments can observe the formation of cracks (e.g., due to lithium cluster formation and stress) as they develop over time during battery usage.

-

After collecting 2D projection images and reconstructing them into a 3D volume, the next crucial step for quantitative analysis is segmentation. This process involves assigning every voxel (3D pixel) in the reconstructed volume to a specific material phase (e.g., anode, cathode, separator, void space, casing). Software tools like VG Studio Max or Dragonfly (which includes deep learning modules for complex segmentations) are used for this.

Once segmented, various quantitative metrics can be extracted:

- Electrode analysis: Curvature of electrodes (e.g., anode overhang), exit angles, thickness.

- Material characterization: Particle size distribution, particle sphericity or shape, porosity, permeability, surface area, and tortuosity (path of lithium ions).

- Defect quantification: Volume and thickness of delamination, void spaces, and other structural defects.

For example, to determine particle size distribution, individual particles within a segmented volume can be separated using techniques like "watershed transformation," allowing for analysis of each particle's dimensions.

-

The main challenge lies in the inherent trade-off between spatial resolution (voxel size) and the field of view. While smaller voxels (higher resolution) are ideal for resolving fine details (e.g., individual fibers or small particles), imaging an entire large battery at very high resolution (e.g., 1 micron for a 100 mm battery) would result in an impractically enormous file size (e.g., 2,000 terabytes) that current computers and software cannot handle.

Conversely, a larger field of view (to encompass an entire battery) necessitates a larger voxel size (lower resolution), which means smaller features may not be resolved accurately or at all. For instance, a 100-micron voxel size for a 100 mm battery reduces the file size to a manageable 16 GB, but smaller features within the battery might not be clearly visible. This necessitates a compromise, often involving initial low-resolution scans of the whole sample to identify areas of interest, followed by higher-resolution scans of those specific regions.

-

Yes, deep learning models can be effectively applied in X-ray CT analysis, particularly for complex segmentation tasks. Software packages like Dragonfly include deep learning modules where users can "paint" small areas to label different material phases (e.g., anode, cathode, delamination space). This labeled data serves as "ground truth" to train a deep learning model. Once trained, this model can be applied to the entire dataset to perform accurate and efficient segmentation.

The main benefits of using deep learning models are:

- Automation and efficiency: Deep learning can automate complex and time-consuming segmentation tasks, especially for intricate structures or large datasets.

- Improved accuracy: Well-trained models can often achieve higher accuracy in identifying and segmenting different phases compared to manual or traditional thresholding methods, particularly in challenging cases.

- Consistency and bias reduction: Once a model is trained, it can be applied consistently across multiple images, including those collected as a function of time, temperature, or from different samples. This eliminates potential human bias that might otherwise be introduced during manual segmentation.

- Time-resolved analysis (4D CT): Deep learning models can facilitate the analysis of time-resolved (4D) CT scans by segmenting corresponding features across different time points, allowing for tracking of critical performance parameters and structural evolution over time.

To ensure optimal performance and comparability when applying a trained model across multiple images, it's recommended to normalize histogram intensities by calibrating the CT scan intensities and ideally collect all data with the same settings (e.g., voxel size).

Subscribe to the X-ray CT Email Updates newsletter

Stay up to date with CT news and upcoming events and never miss an opportunity to learn new analysis techniques and improve your skills.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.

.jpg?width=300&height=300&name=Tim%20Bradow%20(1).jpg)