Application Note EDXRF1990

Scope

The analysis of various plating baths is demonstrated for electroless and electroplating applications.

Background

Metal parts are often plated to create a decorative surface finish or to ensure desired physical properties, such as corrosion and salt resistance, lubricity, protection from wear and abrasion, and to improve the hardness of the plated metal. Electro-plating and electroless plating are commonly used in almost every industry, from aerospace and electronics to the gas and oil industry and general construction. Monitoring the bath composition is vital in quality control to ensure finished parts are plated to the correct thickness to achieve desired properties without over-coating and wasting chemical materials. Applied Rigaku Technologies offers NEX QC benchtop EDXRF analyzer for the measurement of plating bath composition in a small, easy to use tool, ideal for at-line quality checks or quality confirmation in the lab.

Units

1 oz/gal = 7.489 g/L

1 g/L = 0.134 oz/gal

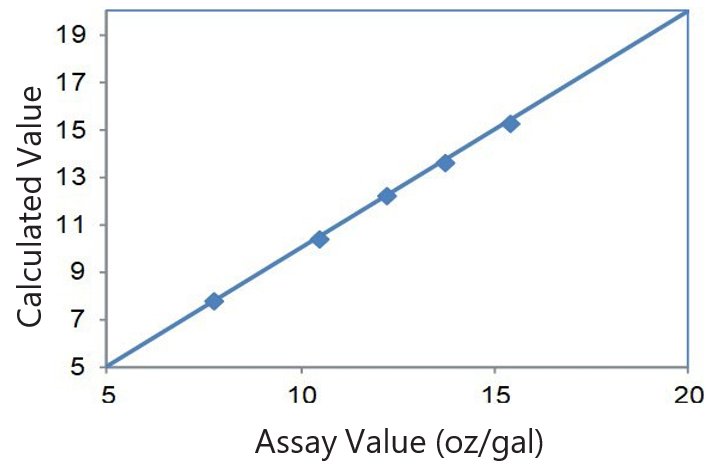

Ni Bath

Calibration

| Element: Ni Units: oz/gal |

||

| Sample I.D. | Assay value | Calculated value |

| 1 | 7.773 | 7.788 |

| 2 | 10.498 | 10.373 |

| 3 | 12.250 | 12.213 |

| 4 | 13.719 | 13.592 |

| 5 | 15.395 | 15.236 |

Correlation plot Ni bath

Correlation plot Ni bath

Recovery and repeatability

To demonstrate recovery and repeatability (precision), low and high calibration standards were analyzed in a static position for 10 consecutive measurements.

| Sample ID | Units | Assay value | NEX QC avg. value | Standard deviation | RSD % |

| Std 1 | oz/gal | 7.773 | 7.742 | 0.037 | 0.5 |

| Std 5 | oz/gal | 15.395 | 15.425 | 0.043 | 0.3 |

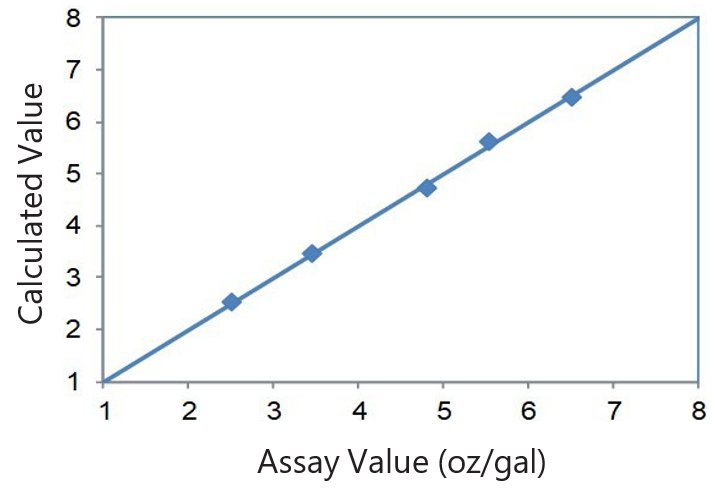

CuCN Bath

Calibration

| Element: CuCN Units: oz/gal |

||

| Sample I.D. | Assay value | Calculated value |

| 1 | 2.500 | 2.518 |

| 2 | 3.457 | 3.464 |

| 3 | 4.800 | 4.710 |

| 4 | 5.545 | 5.627 |

| 5 | 6.500 | 6.483 |

Correlation plot CuCn bath

Correlation plot CuCn bath

Recovery and repeatability

To demonstrate recovery and repeatability (precision), low and high calibration standards were analyzed in a static position for 10 consecutive measurements.

| Sample ID | Units | Assay value | NEX QC avg. value | Standard deviation | RSD % |

| Std 1 | oz/gal | 2.500 | 2.530 | 0.010 | 0.4 |

| Std 5 | oz/gal | 6.500 | 6.531 | 0.015 | 0.2 |

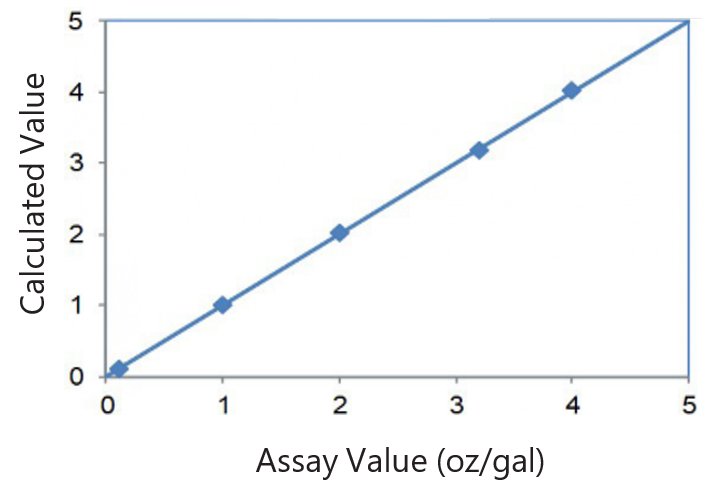

AgCN Bath

Calibration

| Element: AgCN Units: oz/gal |

||

| Sample I.D. | Assay value | Calculated value |

| 1 | 0.100 | 0.099 |

| 2 | 1.000 | 1.000 |

| 3 | 2.000 | 2.011 |

| 4 | 3.200 | 3.179 |

| 5 | 4.000 | 4.011 |

Correlation plot AgCN bath

Correlation plot AgCN bath

Recovery and repeatability

To demonstrate recovery and repeatability (precision), low and high calibration standards were analyzed in a static position for 10 consecutive measurements.

| Sample ID | Units | Assay value | NEX QC avg. value | Standard deviation | RSD % |

| Std 1 | oz/gal | 0.100 | 0.100 | 0.0004 | 0.4 |

| Std 5 | oz/gal | 4.000 | 4.036 | 0.008 | 0.2 |

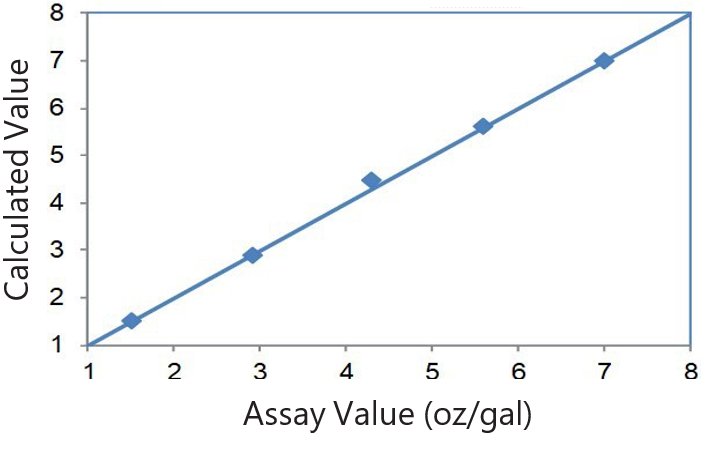

CdCN Bath

Calibration

| Element: CdCN Units: oz/gal |

||

| Sample I.D. | Assay value | Calculated value |

| 1 | 1.500 | 1.500 |

| 2 | 2.905 | 2.911 |

| 3 | 4.300 | 4.469 |

| 4 | 5.597 | 5.636 |

| 5 | 7.000 | 6.986 |

Calibration plot CdCN bath

Calibration plot CdCN bath

Recovery and repeatability

To demonstrate recovery and repeatability (precision), low and high calibration standards were analyzed in a static position for 10 consecutive measurements.

| Sample ID | Units | Assay value | NEX QC avg. value | Standard deviation | RSD % |

| Std 1 | oz/gal | 1.500 | 1.500 | 0.005 | 0.3 |

| Std 5 | oz/gal | 7.000 | 6.997 | 0.033 | 0.5 |

Conclusion

The results indicate NEX QC system yields exceptional performance for the analysis of plating baths. The rugged self-contained system with simple, intuitive software makes the NEX QC analyzer an ideal tool for at-line quality control or in the QC lab itself. This methodology can also be adapted for in-line process control in real time with the Rigaku NEX OL process analyzer.