Application Note EDXRF1457

Scope

The analysis of copper in ore is demonstrated, suitable for exploration and ore grade control at the mine site.

Background

Elemental analysis is crucial for screening samples at the mine site and throughout the processing of ores. During smelting, major and minor elements are also closely monitored in the ore, concentrates, slags, and tails. Rigaku offers the NEX QC Series of analyzers to meet these analytical needs of the mining industry, both at the mine site and the smelter. Simple yet versatile, the NEX QC is transportable for mine site screening, rugged enough for the smelting operations, and powerful enough for work in a central lab. The NEX QC utilizes 50 kV direct excitation and a high- performance semiconductor detector to provide excellent sensitivity in a low-cost tool ideal for analyzing ore materials.

Calibration

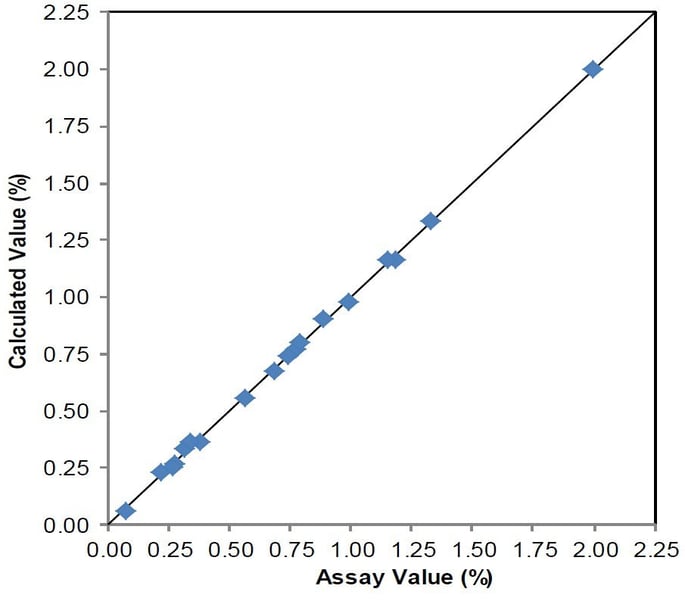

Empirical calibration gives the most accurate means of analysis. A typical calibration plot is provided here using 18 assayed standards provided by a major copper mine containing Fe₃O₄ between 10 – 25%. Alpha corrections are employed to automatically compensate for variations in X-ray absorption and enhancement effects within the sample due to the independent variations in iron content. While as few as 8 standards can be used to calibrate, increasing the number of standards optimizes accuracy.

| Element: Cu Units: % |

||

| Sample I.D. | Assay value | Calculated value |

| UG1 | 0.772 | 0.7686 |

| UG2 | 0.992 | 0.9806 |

| UG3 | 0.275 | 0.2661 |

| UG5 | 0.684 | 0.6751 |

| UG6 | 0.563 | 0.5560 |

| UG8 | 0.741 | 0.7427 |

| UG10 | 1.185 | 1.1655 |

| UG11 | 1.151 | 1.1647 |

| UG13 | 0.071 | 0.0585 |

| UG20 | 0.378 | 0.3657 |

| UG21 | 0.266 | 0.2506 |

| UG22 | 0.791 | 0.8004 |

| UG23 | 0.312 | 0.3327 |

| UG24 | 0.340 | 0.3624 |

| UG25 | 0.219 | 0.2337 |

| UG26 | 1.999 | 1.9978 |

| UG27 | 1.329 | 1.3311 |

| UG28 | 0.888 | 0.9038 |

Correlation plot of copper

Correlation plot of copper

Repeatability

To demonstrate repeatability (precision), low, medium, and high copper samples were chosen from the set of calibration standards. Samples were each measured for ten repeat analyses in static position. Typical results are shown below.

| Sample | Cu standard value (mass %) |

Cu average value (mass %) |

Standard deviation | RSD (%) |

| UG25 | 0.219 | 0.225 | 0.003 | 1.4 |

| UG2 | 0.992 | 0.987 | 0.004 | 0.4 |

| UG26 | 1.999 | 1.999 | 0.010 | 0.5 |

Conclusion

The Rigaku NEX QC offers the copper industry a simple yet powerful and versatile tool for identifying and quantifying elemental composition of a wide variety of materials. The NEX QC is an excellent tool for screening and quantifying copper ore from the mine. Given similar calibration standards for the stages of smelting, control through the beneficiation, sintering, blending and throughout the smelting process can be maintained as well for several elements of interest in addition to copper. With a small footprint and modern touchscreen interface, the modern Rigaku NEX QC analyzer is transportable, rugged and reliable, and ideal for use in copper production