Application Note B-XRI1003

Introduction

In micro X-ray CT, projection images of X-rays transmitted through a minute object are reconstructed to produce a high-resolution 3D transmission image. By displaying the reconstruction image in 2D slices and 3D volume renderings, the inner structures and defects in the object can be analyzed non-destructively. Here, a damaged LED package was subjected to X-ray micro CT and a defective site was revealed.

Measurements and results

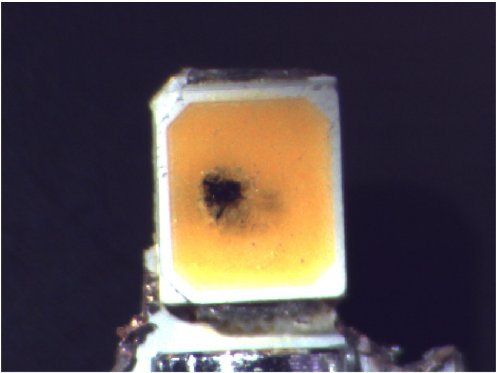

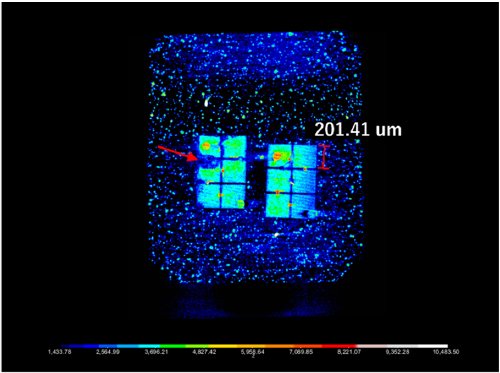

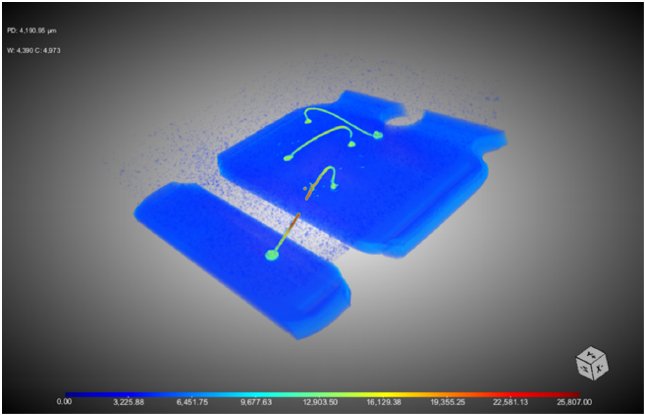

The damaged LED package (Figure 1) was subjected to X-ray micro CT at 1.3 μm/voxel resolution in six hours. Figure 2 shows a slice view of the reconstructed image. The slice view provides cross sections at arbitrary positions as if one is actually slicing the sample. A defective site encompassing two LED chips was found (shown by the red arrow in Figure2). Figure 3 shows a volume rendering view of the reconstructed image. By displaying the 3D volume rendering, one can understand the positional relationships among the LED chips and the bonding wires that the 2D slice view couldn’t clarify. A bonding wire was found to be disconnected. As shown here, 3D micro X-ray CT can magnify and visualize the inner structure of micro objects. It can not only elucidate the shapes and positions of inner objects but also measure distances between them.

Figure 1: A broken LED package

Figure 2: A CT slice image of the LED package

Figure 3: A CT volume rendering image of the LED package