Analysis of Ultrathin Films Using XRF and XRD

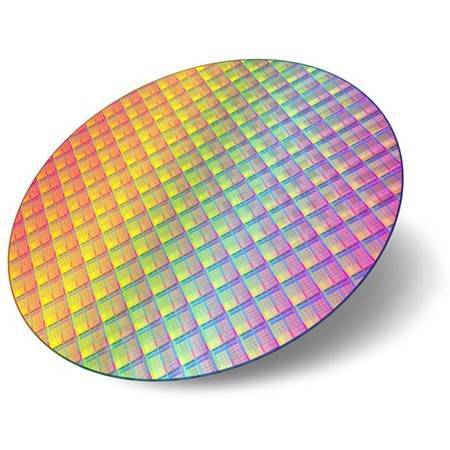

X-ray fluorescence (XRF) and X-ray diffraction (XRD) are essential techniques for analyzing ultrathin films, which are used in various applications like semiconductors, optical coatings, and functional materials. These methods provide valuable information about the composition and structure of thin films.

X-ray fluorescence (XRF) for ultrathin films

XRF is a non-destructive technique that measures the fluorescence X-rays emitted by a sample when irradiated with X-rays. It is primarily used for:

- Elemental composition: XRF can accurately identify the elements in the film.

- Film thickness estimation: By measuring the intensity of emitted X-rays, XRF can also provide information about the film’s thickness.

However, for extremely thin films, XRF may face interference from the substrate, which can affect accuracy.

X-ray diffraction (XRD) for ultrathin films

XRD analyzes the diffraction patterns of X-rays as they interact with the crystal structure of the sample. This technique provides:

- Crystallinity: XRD can determine if the film is crystalline, polycrystalline, or amorphous.

- Stress and strain: It helps assess any internal stress or deformation in the film.

However, XRD may not be as effective for analyzing amorphous films.

Combining XRF and XRD

By combining XRF and XRD, a comprehensive analysis of ultrathin films can be achieved. XRF provides data on composition and thickness, while XRD offers insight into the crystal structure and internal stress. Together, they allow for a more thorough evaluation of the film’s properties, making them indispensable tools in material research and quality control.

Rigaku recommends the following products

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.