What Is In-plane Diffraction Used For?

For thin-film characterization

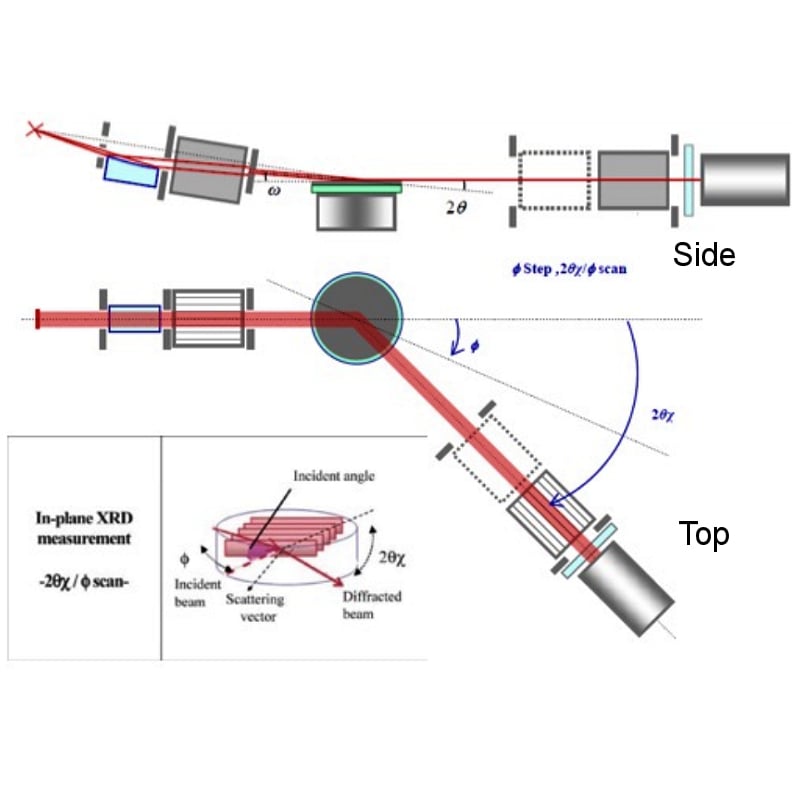

An X-ray diffraction technique in which both the incident and diffracted beams are nearly parallel to the sample surface, in-plane diffraction is an important method for thin film characterization. With standard diffraction geometries, such as the Bragg-Brentano geometry, lattice planes are measured that are parallel to the sample surface. X-rays penetrate to a certain depth into the sample, where they are diffracted; however, if the sample layer is too thin, X-rays are completely transmitted by the sample and no diffraction is observed. In these circumstances, in-plane diffraction is used.

SmartLab’s fifth in-plane horizontal axis measures diffraction in the plane of the sample surface. Ultra–thin films less than a single nanometer thick and the texture of surface layers can be analyzed without re-positioning the sample to an unstable vertical orientation. By coupling in-plane and vertical scanning axes, the structure of textured bulk materials can be completely measured. The sample always remains in a horizontal position. Horizontal sample placement also allows use of the full line focus beam dramatically reducing measurement time. No need to convert to point focus before scanning. With Smartlab’s CBO technology and 5-circle goniometer, scientists have access to more complex experiments that are easier to perform.

In-plane diffraction has two major features: The penetration depth of the beam is limited to within about 100 nm of the surface. The technique measures lattice planes that are (nearly) perpendicular to the sample surface, which are inaccessible by other techniques.

Rigaku recommends the following products

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.