Application Note WDXRF1105

Introduction

Lubricating oil is given functional properties for specific purposes by mixing additives with base oil. Therefore, it is very important to control concentrations of additive elements in lubricating oil production plants.

X-ray fluorescence (XRF) spectrometry has been used for quantitative analysis of additive elements such as Mg, P and Zn in lubricating oil owing to the high precision and simple sample preparation of XRF analysis. In XRF analysis of lubricating oil, a sample is simply poured into a liquid cell. No complicated treatment, such as chemical decomposition or dilution, is required.

This application note demonstrates quantitative analysis of lubricating oil according to ASTM D6443-14 on the Rigaku ZSX Primus IVi, a wavelength dispersive XRF spectrometer.

Instrument

The ZSX Primus IVi, a tube-below sequential wavelength dispersive X-ray fluorescence (WDXRF) spectrometer, is optimized for the routine analyses that today’s petroleum laboratories need to perform. The programmably switchable vacuum seal between the sample and optical chambers can keep the optical chamber under vacuum and the sample chamber under helium. This minimizes helium gas consumption and the time required for atmosphere change in the sample chamber. The spectrometer is equipped with a 3 kW X-ray tube and analyzing crystals covering O to Cm. If higher sensitivity or precision is required, a 4 kW X-ray tube is available.

The control software is designed for ease of use in routine analyses. The Flowbar in quantitative analysis guides users through the process of establishing calibrations. The Sample ID Table and Program Operation help operators carry out daily analysis.

Sample and sample preparation

Reference standard samples of lubricating oil provided by Analytical Services, Inc. were used for calibration. Eight grams of each lubricating oil sample was poured into a liquid cell (Chemplex® 1095) with 3.6 μm Mylar® (Chemplex® 150) sample film.

Figure 1: Oil sample cell

Measurement and calibration

Measurements were performed on the ZSX Primus IVi with a 3 kW Rh-target X-ray tube for Ca, Cl, Cu, Mg, P, S and Zn. A primary beam filter was inserted between the sample and the X-ray tube. The filter protects the X-ray tube window against damage from samples leaking during measurement. In addition, the Al filter reduces the background to improve the ratio of peak intensity to background intensity. Measurement conditions are shown in Table 1.

Table 1: Measurement conditions

| Path atmosphere | Helium/Vacuum |

| Analysis area | 30 mm in diameter |

| Element | Ca | Cl | Cu | Mg | P | S | Zn |

| Line | Kα | Kα | Kα | Kα | Kα | Kα | Kα |

| kV-mA | 40-60 | 30-80 | 50-48 | 30-80 | 30-80 | 30-80 | 50-48 |

| Primary filter | Be30 | Be30 | Al125 | Be30 | Be30 | Be30 | Al125 |

| Slit | S4 | S2 | S2 | S4 | S4 | S4 | S2 |

| Crystal | LiF | GeH | LiF | RX26 | GeH | GeH | LiF |

| Detector | PC | PC | SC | PC | PC | PC | SC |

| Time Peak(s) | 16 | 40 | 10 | 40 | 40 | 10 | 10 |

| BG(s) | 8 | 20 | 4x2 | 10x2 | 20 | 4 | 4x2 |

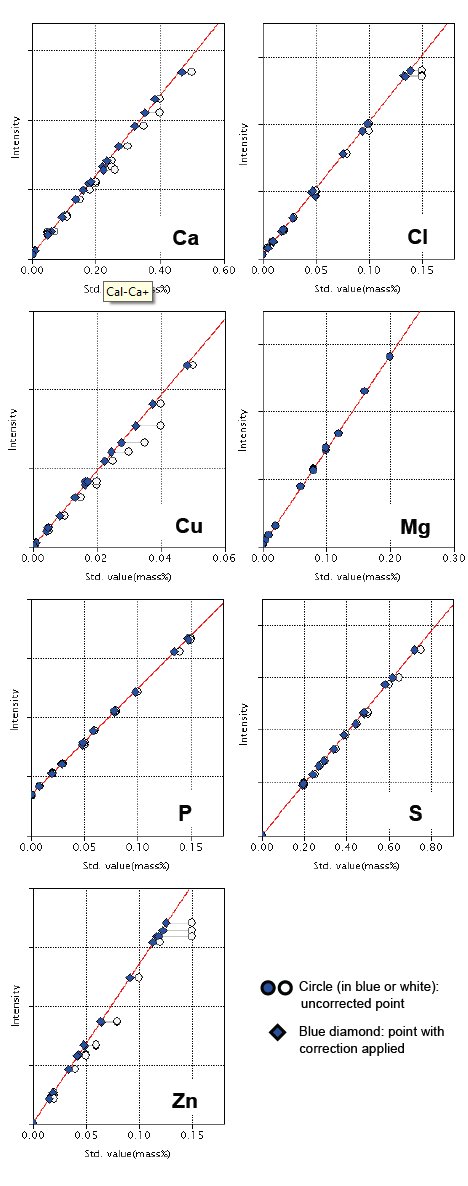

The calibration curves were generated with matrix correction applied to all analytes except Mg, as indicated in ASTM D6443-14. The correction coefficients used were calculated theoretically by the fundamental parameter (FP) method. The calibration results are listed in Table 2 and the calibration curves are shown in Figure 2.

Table 2: Calibration results (unit: mass%)

| Element | Calibration range | Accuracy |

| Ca | 0 – 0.50 | 0.0053 |

| Cl | 0 – 0.15 | 0.0005 |

| Cu | 0 – 0.05 | 0.0003 |

| Mg | 0 – 0.20 | 0.0012 |

| P | 0 – 0.15 | 0.0009 |

| S | 0 – 0.75 | 0.0037 |

| Zn | 0 – 0.15 | 0.0008 |

The accuracy of calibration is calculated by the following formula:

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-2} }$

$C_i$: calculated value of standard sample

$\hat{C}_i$: reference value of standard sample

n : number of standard samples.

Figure 2: Calibration curve with matrix correction for lubricating oil

Figure 2: Calibration curve with matrix correction for lubricating oil

Analysis results

Repeatability tests were carried out for two different samples. For each sample, two aliquots were prepared and quantified with the calibration (Figure 2); this process was repeated twenty times. The test results are tabulated in Table 3, in which the average and the difference between the two aliquots are shown and “r” represents “repeatability” defined in ASTM D6443-14, which states that the difference between successive test results obtained by the same operator with the same apparatus under constant operation conditions on identical test material would, in the long run, in the normal and correct operation of the test method, exceed the values in Table 4, which lists the repeatability (r) of each analyte, in only one case in twenty.

The test results shown in Table 3, where the difference between two aliquots does not exceed the repeatability (r) for each analyte, prove that the performance of the ZSX Primus IVi meets the requirement of ASTM D6443-14.

Table 3: Repeatability test results (unit: mass%)

| Ca | Cl | Cu | Mg | |||||

| Avg. | Diff. | Avg. | Diff. | Avg. | Diff. | Avg. | Diff. | |

| 1 | 0.1889 | 0.0002 | 0.0491 | 0.0001 | 0.0200 | 0.0001 | 0.0730 | 0.0014 |

| 2 | 0.1891 | 0.0005 | 0.0489 | 0.0002 | 0.0199 | 0.0002 | 0.0738 | 0.0029 |

| 3 | 0.1894 | 0.0001 | 0.0490 | 0.0003 | 0.0199 | 0.0002 | 0.0742 | 0.0021 |

| 4 | 0.1892 | 0.0004 | 0.0492 | 0.0001 | 0.0200 | 0.0000 | 0.0736 | 0.0009 |

| 5 | 0.1891 | 0.0002 | 0.0490 | 0.0004 | 0.0200 | 0.0001 | 0.0736 | 0.0009 |

| 6 | 0.1891 | 0.0002 | 0.0490 | 0.0003 | 0.0200 | 0.0001 | 0.0740 | 0.0018 |

| 7 | 0.1891 | 0.0002 | 0.0493 | 0.0004 | 0.0200 | 0.0001 | 0.0733 | 0.0032 |

| 8 | 0.1892 | 0.0000 | 0.0492 | 0.0006 | 0.0199 | 0.0001 | 0.0728 | 0.0022 |

| 9 | 0.1892 | 0.0001 | 0.0489 | 0.0001 | 0.0199 | 0.0001 | 0.0735 | 0.0009 |

| 10 | 0.1891 | 0.0000 | 0.0487 | 0.0002 | 0.0200 | 0.0001 | 0.0732 | 0.0003 |

| 11 | 0.1890 | 0.0003 | 0.0486 | 0.0000 | 0.0199 | 0.0002 | 0.0729 | 0.0008 |

| 12 | 0.1888 | 0.0000 | 0.0489 | 0.0006 | 0.0199 | 0.0001 | 0.0734 | 0.0018 |

| 13 | 0.1890 | 0.0003 | 0.0488 | 0.0008 | 0.0200 | 0.0001 | 0.0738 | 0.0011 |

| 14 | 0.1893 | 0.0003 | 0.0484 | 0.0000 | 0.0199 | 0.0002 | 0.0729 | 0.0007 |

| 15 | 0.1893 | 0.0003 | 0.0485 | 0.0002 | 0.0199 | 0.0001 | 0.0720 | 0.0010 |

| 16 | 0.1890 | 0.0003 | 0.0491 | 0.0010 | 0.0199 | 0.0000 | 0.0727 | 0.0023 |

| 17 | 0.1889 | 0.0001 | 0.0494 | 0.0005 | 0.0199 | 0.0001 | 0.0725 | 0.0027 |

| 18 | 0.1890 | 0.0002 | 0.0491 | 0.0001 | 0.0199 | 0.0002 | 0.0725 | 0.0028 |

| 19 | 0.1890 | 0.0002 | 0.0488 | 0.0004 | 0.0200 | 0.0001 | 0.0718 | 0.0042 |

| 20 | 0.1891 | 0.0004 | 0.0488 | 0.0003 | 0.0199 | 0.0000 | 0.0713 | 0.0031 |

| Max | 0.0005 | 0.0010 | 0.0002 | 0.0042 | ||||

| r | 0.0030 | 0.0020 | 0.0005 | 0.0068 | ||||

| P | S | Zn | ||||||

| Avg. | Diff. | Avg. | Diff. | Avg. | Diff. | |||

| 1 | 0.0502 | 0.0004 | 0.2793 | 0.0001 | 0.0489 | 0.0002 | ||

| 2 | 0.0499 | 0.0003 | 0.2790 | 0.0007 | 0.0489 | 0.0002 | ||

| 3 | 0.0497 | 0.0001 | 0.2788 | 0.0004 | 0.0489 | 0.0001 | ||

| 4 | 0.0501 | 0.0010 | 0.2784 | 0.0012 | 0.0489 | 0.0000 | ||

| 5 | 0.0503 | 0.0006 | 0.2781 | 0.0006 | 0.0488 | 0.0002 | ||

| 6 | 0.0501 | 0.0001 | 0.2785 | 0.0001 | 0.0489 | 0.0003 | ||

| 7 | 0.0500 | 0.0003 | 0.2784 | 0.0002 | 0.0489 | 0.0002 | ||

| 8 | 0.0499 | 0.0002 | 0.2776 | 0.0014 | 0.0489 | 0.0001 | ||

| 9 | 0.0499 | 0.0002 | 0.2770 | 0.0002 | 0.0489 | 0.0001 | ||

| 10 | 0.0499 | 0.0002 | 0.2773 | 0.0003 | 0.0489 | 0.0002 | ||

| 11 | 0.0498 | 0.0004 | 0.2774 | 0.0000 | 0.0490 | 0.0001 | ||

| 12 | 0.0498 | 0.0004 | 0.2782 | 0.0015 | 0.0489 | 0.0001 | ||

| 13 | 0.0500 | 0.0001 | 0.2783 | 0.0012 | 0.0488 | 0.0000 | ||

| 14 | 0.0499 | 0.0001 | 0.2780 | 0.0006 | 0.0488 | 0.0000 | ||

| 15 | 0.0499 | 0.0001 | 0.2778 | 0.0011 | 0.0489 | 0.0001 | ||

| 16 | 0.0500 | 0.0001 | 0.2776 | 0.0008 | 0.0489 | 0.0001 | ||

| 17 | 0.0499 | 0.0002 | 0.2781 | 0.0002 | 0.0488 | 0.0000 | ||

| 18 | 0.0498 | 0.0000 | 0.2793 | 0.0021 | 0.0489 | 0.0002 | ||

| 19 | 0.0498 | 0.0000 | 0.2784 | 0.0039 | 0.0489 | 0.0002 | ||

| 20 | 0.0497 | 0.0002 | 0.2773 | 0.0017 | 0.0489 | 0.0001 | ||

| Max | 0.0010 | 0.0039 | 0.0003 | |||||

| r | 0.0026 | 0.0075 | 0.0015 | |||||

Table 3: Repeatability test results (continued) (unit: mass%)

| Ca | P | S | Zn | |||||

| Avg. | Diff. | Avg. | Diff. | Avg. | Diff. | Avg. | Diff. | |

| 1 | 0.0576 | 0.0000 | 0.0813 | 0.0008 | 0.2999 | 0.0016 | 0.1233 | 0.0005 |

| 2 | 0.0575 | 0.0002 | 0.0810 | 0.0001 | 0.2996 | 0.0009 | 0.1234 | 0.0003 |

| 3 | 0.0575 | 0.0001 | 0.0809 | 0.0003 | 0.2997 | 0.0007 | 0.1231 | 0.0002 |

| 4 | 0.0575 | 0.0000 | 0.0807 | 0.0000 | 0.2994 | 0.0001 | 0.1229 | 0.0002 |

| 5 | 0.0575 | 0.0001 | 0.0809 | 0.0003 | 0.2993 | 0.0002 | 0.1231 | 0.0006 |

| 6 | 0.0576 | 0.0003 | 0.0814 | 0.0007 | 0.3004 | 0.0023 | 0.1233 | 0.0002 |

| 7 | 0.0576 | 0.0002 | 0.0816 | 0.0003 | 0.3008 | 0.0015 | 0.1230 | 0.0005 |

| 8 | 0.0576 | 0.0001 | 0.0815 | 0.0001 | 0.3001 | 0.0002 | 0.1229 | 0.0004 |

| 9 | 0.0577 | 0.0001 | 0.0812 | 0.0007 | 0.3000 | 0.0004 | 0.1233 | 0.0004 |

| 10 | 0.0581 | 0.0008 | 0.0808 | 0.0000 | 0.2990 | 0.0016 | 0.1234 | 0.0002 |

| 11 | 0.0579 | 0.0012 | 0.0808 | 0.0000 | 0.2988 | 0.0012 | 0.1229 | 0.0009 |

| 12 | 0.0573 | 0.0001 | 0.0808 | 0.0000 | 0.2995 | 0.0002 | 0.1227 | 0.0006 |

| 13 | 0.0574 | 0.0003 | 0.0807 | 0.0003 | 0.2996 | 0.0000 | 0.1231 | 0.0001 |

| 14 | 0.0575 | 0.0001 | 0.0806 | 0.0001 | 0.2991 | 0.0011 | 0.1230 | 0.0002 |

| 15 | 0.0577 | 0.0005 | 0.0807 | 0.0002 | 0.2997 | 0.0023 | 0.1231 | 0.0003 |

| 16 | 0.0576 | 0.0007 | 0.0808 | 0.0000 | 0.3003 | 0.0011 | 0.1231 | 0.0002 |

| 17 | 0.0573 | 0.0002 | 0.0809 | 0.0001 | 0.2998 | 0.0001 | 0.1232 | 0.0003 |

| 18 | 0.0575 | 0.0002 | 0.0812 | 0.0006 | 0.3000 | 0.0004 | 0.1233 | 0.0000 |

| 19 | 0.0576 | 0.0000 | 0.0810 | 0.0010 | 0.3000 | 0.0005 | 0.1232 | 0.0002 |

| 20 | 0.0576 | 0.0000 | 0.0805 | 0.0000 | 0.2993 | 0.0008 | 0.1232 | 0.0002 |

| Max | 0.0012 | 0.0010 | 0.0023 | 0.0009 | ||||

| r | 0.0017 | 0.0036 | 0.0080 | 0.0028 | ||||

Table 4: Repeatability defined in ASTM D6443-14 (unit: mass%)

| Element | Concentration range | Repeatability [ r ] |

| Ca | 0.001 – 0.200 | 0.006914 (X+0.0007)0.5 |

| Cl | 0.001 – 0.030 | 0.0356 (X+0.0086) |

| Cu | 0.001 – 0.030 | 0.002267 (X+0.0013)0.4 |

| Mg | 0.003 – 0.200 | 0.01611 (X+0.0008)0.333 |

| P | 0.001 – 0.200 | 0.02114 X0.7 |

| S | 0.030 – 0.800 | 0.02371 X0.9 |

| Zn | 0.001 – 0.200 | 0.01225 X0.7 |

Conclusions

Lubricating oil can be routinely analyzed with high accuracy and precision on the ZSX Primus IVi with a 3 kW X-ray tube.

This application note demonstrates that the performance of the ZSX Primus IVi meets the requirement of ASTM D6443-14. In addition, the ZSX Primus IVi can also be applied to the standard method of ASTM D4927-10, which covers a higher concentration range of additive elements in lubricating oil.

Reference

ASTM D6443-14 (2019) Standard Test Method for Determination of Calcium, Chlorine, Copper, Magnesium, Phosphorus, Sulfur, and Zinc in Unused Lubricating Oils and Additives by Wavelength Dispersive X-ray Fluorescence Spectrometry (Mathematical Correction Procedure)