Application Note TA5005

Introduction

DSC can be used to measure differences in structure or state.

For materials such as polyethylene resin, differences in density or state result in different fusion temperatures and energies, which can be observed by DSC.

Instrument

DSC8231, featuring a new electric furnace and new electric furnace circuit technology, this system offers low noise and improved baseline stability.

Measurement and analysis

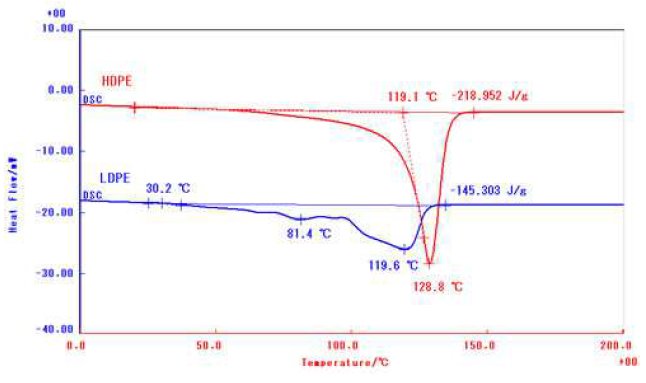

The fusion of HDPE and LDPE measurement result is shown Figure 1. The measurement result is a fusion peak of high density polyethylene (HDPE) where the sharp endothermic peak started near 20℃.

The fusion peak of low density polyethylene (LDPE) reveals an endothermic peak containing several peaks from 30℃. LDPE has a broad fusion peak than HDPE. These two measurement results show the peak fusion temperature, the energy amount and the peak shape are different due to difference of density in same polyethylene resin.

Figure 1: Fusion of HDPE and LDPE

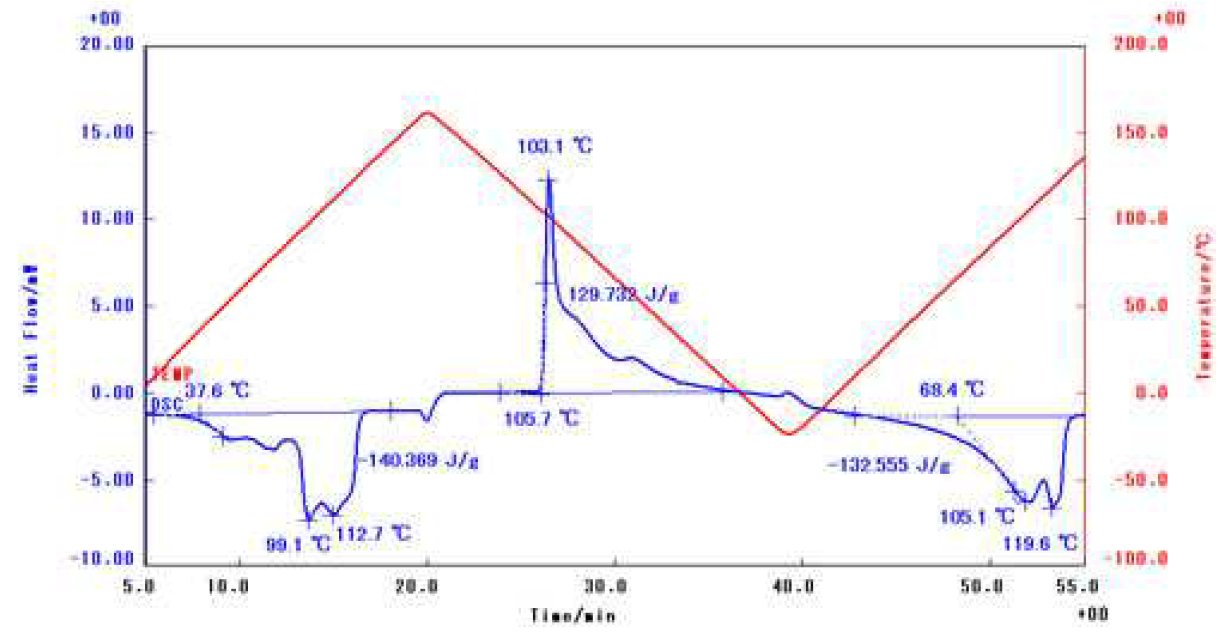

Figure 2 illustrates the measurement of liner low density polyethylene. The measurement consists of first heating, cooling and second heating continuously.

During heating, an endothermic peak due to fusion is observed and, during the cooling process, an exothermic peak is observed due to crystallization. However, because the reheating of fusion depends on the conditions of crystallization in the previous cooling process, the pattern of the endothermic peak is different from the initial heating.

Figure 2: Fusion of LLDPE