ZSX Primus III NEXT

Tube-Above Sequential Wavelength Dispersive X-ray Fluorescence Spectrometer for Industrial Applications

Elemental analysis of solid samples

Rigaku ZSX Primus III NEXT delivers rapid elemental industrial quality control by quantitative determination of major and minor elements from Be through Cm for powder and solid samples.

This new scanning wavelength dispersive X-ray fluorescence spectrometer features Rigaku’s unique X-ray tube-above configuration and is built upon the succesful ZSX Primus series platform.

ZSX Primus III NEXT Overview

Geared for industrial applications

The ZSX Primus III NEXT is an ideal tool for any industrial application, requiring elemental analysis, such as

∘ Minerals and Mining∘ Metals

∘ Cement

∘ Ceramics and Refractories

∘ Glass Manufacturing

∘ Petrochemicals

∘ Chemicals

∘ Environment

Turnkey application packages

Industry-specific application packages are available. The "Pre-Calibration Package," which stores calibration curves at the time of shipment, the "Calibration Package," which includes standard samples and analysis conditions, and the "Master Matching Library" for standardless analysis (SQX) which is specialized for certain types of products, are available to help users start up the analysis operations.

Easy application sharing

The ZSX Primus III NEXT, ZSX Primus IV, and ZSX Primus IVi share the same hardware and software platform, making it easy to share applications between spectrometers.

Improved quality of analytical results

Have confidence in each analysis result. Measurement statistics and spectrometer physical parameters can be displayed with each analysis result to easily spot irregularities.

ZSX Primus III NEXT—your ideal partner for fast and reliable production control in highly demanding industrial environments.

ZSX Primus III NEXT Features

ZSX Primus III NEXT Specifications

| Analytical range | ₈O - ₉₆Cm standard (₄Be - ₉₆Cm Optional - depending on crystal configurations) | |

|---|---|---|

| Spectral method | Wavelength dispersive X-ray fluorescence | |

| Atmosphere | Vacuum | |

| X-ray tube | End window type Rh target 3 kW | |

| Irradiation method | Tube-above | |

| Sample changer | Expandable sample changer with up to 48 positions | |

| Sample inlet | Air lock system | |

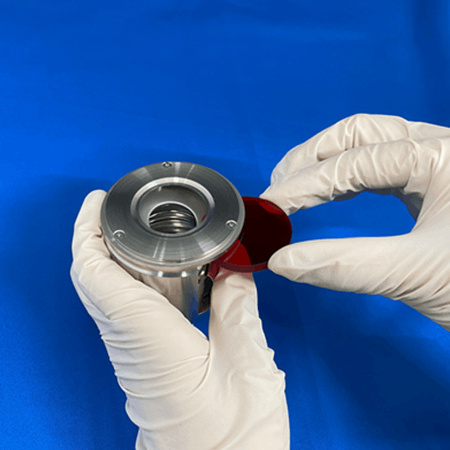

| Maximum sample size | φ 52 mm × 30 mm (H) | |

| Primary filter | Ni400, Ni40, Al125, Al25 | |

| Primary Soller slit | 3 positions automatic exchange machanism Standard and fine slits Optional: Ultralight element slit |

|

| Analyzing crystal | Standard: LiF, 200, PET, RX26 | |

| Pulse height analyzer | Digital multichannel analyzer (DMCA) | |

| Detector | SC (Scintillation counter) F-PC (Gas flow proportional counter) Optional: S-PC LE (Gas sealed proportional counter: does not require P-10 gas) |

|

| Power requirements | Instrument: Single (200 - 240 V), three phase (200 V) 50/60 Hz 40A Personal computer: 1-phase, 100-240 V, 10A |

|

ZSX Primus III NEXT Options

The following accessories are available for this product:

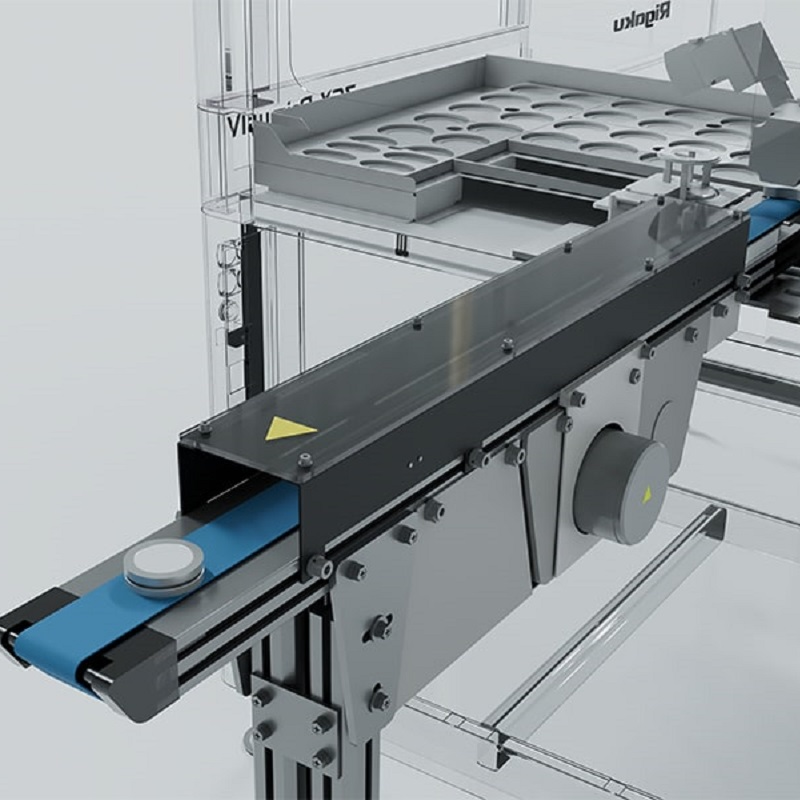

Automation Solution

Automatically transports measurement samples to the instrument, enabling continuous measurement.

ZSX Primus III NEXT Application Notes

The following application notes are relevant to this product

-

XRF1131 - Standardless FP Analysis of Lithium-ion Battery Cathode Material LiFePO₄ by ZSX Primus IV

-

BATT0004 - Chemical Composition Analysis of NMC Cathode

-

BATT0001 - Battery Material Development

-

WDXRF1126 - Accurate Quantitative Analysis of Ferrosilicon by the Fusion Method using ZSX Primus III NEXT

-

WDXRF1124 - Quantitative Analysis of Blast Furnace Slag by Fusion Method on the ZSX Primus III NEXT

-

WDXRF1121 - Quantitative Analysis of Cast Iron using ZSX Primus III NEXT

-

WDXRF1123 - Quantitative Analysis of Stainless Steel using the ZSX Primus III NEXT

-

WDXRF1122 - Silicate Rock Analysis by Fusion Bead Method on ZSX Primus III NEXT

-

WDXRF1120 - Quantitative Analysis of Low Alloy Steel using the ZSX Primus III NEXT

-

WDXRF1119 - Cement Raw Meal Analysis by Pressed Powder Method on the ZSX Primus III NEXT

-

WDXRF1099 - Trace Element Analysis in Geological Samples by the Pressed Powder Method, using GEO-TRACE-PAK

-

WDXRF1085 - Trace Element Analysis for Water Solution by Micro-droplet Method using Ultra Carry Filter Paper

-

WDXRF1077 - Sulfur Analysis in Crude Oil and High-sulfur Fuels by WDXRF according to ASTM D2622-16

-

WDXRF1068 - Silicate Rock Analysis by Fusion Method

-

WDXRF1019 - Silicate Rock Analysis by Fusion Method

-

WDXRF1071 - Semi-quantitative FP Analysis of Geological Samples

-

WDXRF1021 - Quantitative Analysis of Stainless Steel

-

WDXRF1009 - Quantitative Analysis of Low Alloy Steel

-

WDXRF1017 - Quantitative Analysis of Cast Iron

-

WDXRF1118 - Quality and Process Control Analysis of Natural and Processed Iron Ores by the Pressed Powder Method

-

WDXRF1076 - Analysis of Low-concentration Sulfur in Petroleum-based Fuels per ASTM D2622-16

-

WDXRF1101 - Fused Bead Analysis for Refractories using Application Package Refractory Series

-

WDXRF1100 - Fused Bead Analysis for Wide Concentration Ranges of Various Oxide Materials using OXIDE-FB-PAK

-

WDXRF1092 - Fixed Angle Measurement using the Semi-Quantitative Analysis Function SQX of ZSX Guidance Software

-

WDXRF1096 - Fe, Ni and Co Based Alloy Analysis by Fundamental Parameter Method using ZSX Primus III+

-

WDXRF1066 - Determination of Chemical Composition of Nickel Laterite Ore by Fusion Method

-

WDXRF1027 - Cu Concentrate with Advanced Correction for Fused Beads

-

WDXRF1005 - Cement by Pressed Powder Method ASTM C114-11

-

WDXRF1086 - Boron and Fluorine Quantitative Analysis for Water Solution by Micro-droplet Method using Ultra Carry Filter Paper

-

WDXRF1025 - Quantitative Analysis of Blast Furnace Slag by the Pressed Powder Method

-

WDXRF1054 - Analysis of S, Fe, Ni and V in Residual Oil According to IP610/13

-

WDXRF1002 - Analysis of Iron Ores by Oressed Powder Method

-

WDXRF1089 - Analysis of Hazardous Heavy Elements in Soil and Sediment using ZSX Primus IV

-

WDXRF1026 - Accurate Quantitative Analysis of Ferrosilicon by the Fusion Method

-

WDXRF1024 - Quantitative Analysis of Blast Furnace Slag by Fusion Method

ZSX Primus III NEXT Resources

Webinars

Visit the Webinar resource page to access Webinars relevant to ZSX Primus III NEXT

Rigaku Journal articles

Visit the Rigaku Journal resource page to access articles relevant to ZSX Primus III NEXT

Publications

Visit the Publication Library to access articles relevant to ZSX Primus III NEXT

ZSX Primus III NEXT Events

Learn more about our products at these events

-

EventDatesLocationEvent website

-

Webinar: Quantitative Analysis with XRF – Calibration Steps for Accurate ResultsFebruary 27 2026 - February 27 2026Webinar

-

Prospectors & Developers Assoc of Canada 2026March 1 2026 - March 4 2026Toronto, ON, Canada

-

Anwendertreffen Röntgenfluoreszenz- und FunkenemissionsspektrometrieMarch 3 2026 - March 4 2026Münster, Germany

-

Rigaku UK User Meeting 2026March 4 2026 - March 5 2026Oxfordshire, UK

-

Pittcon 2026March 9 2026 - March 11 2026San Antonio, TX, USA

-

APS 2026March 16 2026 - March 20 2026Denver, CO, USA

-

ACS Spring 2026March 22 2026 - March 26 2026Atlanta, GA, USA

-

International Battery 2026March 23 2026 - March 26 2026Orlando, FL, USA

-

AnalyticaMarch 24 2026 - March 27 2026Munich, Germany

-

Chembio ExhibitionApril 15 2026 - April 16 2026Helsinki, Finland

-

MRS Spring 2026April 26 2026 - May 1 2026Hawaii, HI, USA

-

Canadian Chemistry Conf 2026May 24 2026 - May 28 2026Toronto, ON, Canada

-

3rd Global CemCCUS Conference, ExhibitioJune 9 2026 - June 10 2026Hamburg, Germany

-

Denver X-ray Conference (DXC) 2026August 3 2026 - August 7 2026Lombard, IL, USA

-

12th Pacific Rim International Conference on Advanced Materials and Processing (PRICM12)August 9 2026 - August 13 2026Gold Coast Queensland, Australia

-

ACS Fall 2026August 23 2026 - August 27 2026Chicago, IL, USA

-

MS&T 2026October 4 2026 - October 7 2026Pittsburgh, PA, USA

-

GSA 2026October 11 2026 - October 14 2026Denver, CO, USA

-

Gulf Coast Conference (GCC) 2026October 13 2026 - October 15 2026Galveston, TX, USA

-

AAPS PharmSci 360 - 2026October 25 2026 - October 28 2026New Orleans, LA, USA

-

SERMACS 2026November 4 2026 - November 7 2026Memphis, TN, USA

-

Eastern Analytical Symposium (EAS) 2026November 16 2026 - November 18 2026New Jersey

-

MRS Fall 2026November 29 2026 - December 4 2026Boston, MA, USA

-

Advanced Automotive Battery Conf 2026December 8 2026 - December 11 2026Las Vegas, NV, USA

ZSX Primus III NEXT

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.