Application Note WDXRF1062

Introduction

Glass is very common material used in various situations with long historical roots. Soda-lime glass is considered to be the first human made glass, and is still being used in many forms such as light bulbs for lamps, touch panels, LCD monitors, solar panels, insulators, tableware, containers, windows and mirrors. Although the basic component of glass is SiO₂, elements such as Na₂O and CaO are added to change the characteristics of the glass depending on the intended use. Addition of different elements in certain quantities can change the physical and chemical properties such as melting point, moisture resistance and thermal expan-sion. Some trace elements can color glass.

X-ray fluorescence (XRF) analysis quickly and easily offers precise elemental analysis results allowing control of glass composition in the production process. This application note describes the excellent performance of Supermini200 for the analysis of soda-lime glass.

Instrument

The Supermini200 is a benchtop sequential wavelength dispersive XRF (WDXRF) spectrometer designed specifically to deliver excellent performance while eliminating conventional installation requirements such as cooling water, special power supply and large floor space. By selecting the optional sealed proportional counter instead of the gas flow proportional counter, requirement of P10 gas can be eliminated as well, realizing a truly utility free WDXRF instrument.

Featuring a unique air-cooled 200W X-ray tube, two detectors, up to three analyzing crystals with selectable vacuum or helium atmosphere, the Supermini200 can analyze elements from oxygen to uranium.

The Windows®-based software used to operate the Supermini200 shares the same platform running Rigaku’s popular high-power WDXRF ZSX family instruments. This means that it has the same advanced algorithms, multiple language support and an intuitive user-friendly interface.

Standards and Sample Preparation

NIST glass disk standards were measured to set up calibrations.

The glass samples were measured without sample preparation.

Measurement and calibration

Measurements for nine elements SiO₂, Na₂O, CaO, MgO, SO₃, Al₂O₃, Fe₂O₃, K₂O and TiO₂ were performed on the Supermini200.

Measurement conditions are shown in Table 1.

Table 1: Measurement conditions

| Element | Si | Na | Ca | Mg | S |

| Line | Kα | Kα | Kα | Kα | Kα |

| kV-mA | 50-4.0 | 50-4.0 | 50-4.0 | 50-4.0 | 50-4.0 |

| Primary Filter | OUT | OUT | OUT | OUT | OUT |

| Crystal | PET | RX25 | PET | RX25 | PET |

| Detector | F-PC | F-PC | SC | F-PC | F-PC |

| Time (s) | 40 | 40 | 40 | 40 | 40 |

| Element | Al | Fe | K | Ti | |

| Line | Kα | Kα | Kα | Kα | |

| kV-mA | 50-4.0 | 50-4.0 | 50-4.0 | 50-4.0 | |

| Primary Filter | OUT | OUT | OUT | OUT | |

| Crystal | PET | LiF(200) | PET | LiF(200) | |

| Detector | F-PC | SC | F-PC | SC | |

| Time (s) | 40 | 40 | 40 | 40 |

The calibration curves were generated using the following CRMs shown below:

- National Institute of Standards and Technology (NIST) standards SRM 620, 621, 1830 and 1831

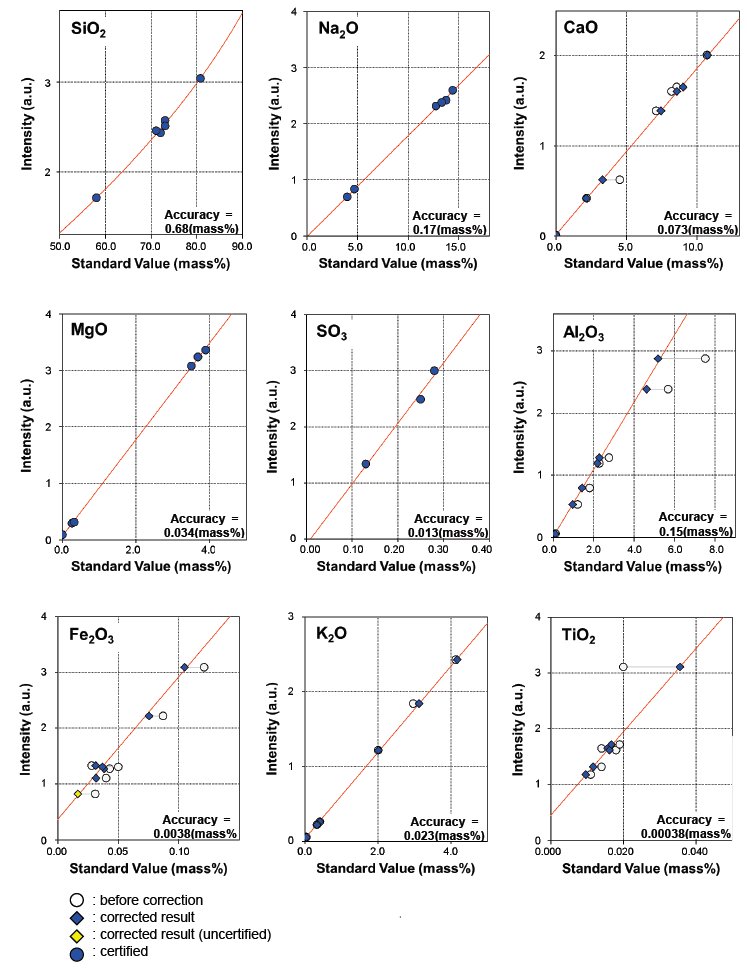

In order to extend the calibration range, NIST glass standards SRM 93a, 1411, and 1412 were added. Matrix (theoretical alpha) correction was applied to the components except for SiO₂, Na₂O, MgO and SO₃. The correction coefficients were calculated by the fundamental parameter (FP) method. The calibration curves are shown in Figure 1 and the calibration results are listed in Table 2.

Figure 1: Calibration curves of common components in soda-lime glass.

Figure 1: Calibration curves of common components in soda-lime glass.

Table 2: Calibration results (unit : mass%)

| Component | Calibration range | Accuracy |

| SiO₂ | 58.04 - 80.8 | 0.68 |

| Na₂O | 3.98 - 14.39 | 0.17 |

| CaO | 0.01 - 10.71 | 0.073 |

| MgO | 0.005 - 3.91 | 0.034 |

| SO₃ | 0.13 - 0.28 | 0.013 |

| Al₂O₃ | 0.12 - 7.52 | 0.15 |

| Fe₂O₃ | 0.031 - 0.121 | 0.0038 |

| K₂O | 0.014 - 4.14 | 0.023 |

| TiO₂ | 0.011 - 0.02 | 0.00038 |

The accuracy of the calibration curves are calculated by the following equation:

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-m} }$

$C_i$: calculated value of standard sample

$\hat{C}_i$: reference value of standard sample

n : number of standard samples.

m: degree of freedom (linear 2, quad. 3)

Analysis Results

Repeatability test for soda-lime glass was carried out and the result is shown in Table 3. The standard deviations for both major and minor components are very small.

Table 3: Repeatability test results for a soda-lime glass disk (unit : mass%)

| SiO₂ | Na₂O | CaO | MgO | SO₃ | Al₂O₃ | Fe₂O₃ | K₂O | TiO₂ * | |

| N=1 | 69.82 | 12.83 | 8.50 | 3.37 | 0.12 | 1.95 | 0.071 | 1.40 | 0.040 |

| 2 | 69.85 | 12.92 | 8.51 | 3.36 | 0.12 | 1.96 | 0.070 | 1.41 | 0.038 |

| 3 | 69.85 | 12.92 | 8.51 | 3.37 | 0.12 | 1.96 | 0.071 | 1.41 | 0.037 |

| 4 | 69.84 | 12.89 | 8.51 | 3.33 | 0.13 | 1.96 | 0.071 | 1.40 | 0.038 |

| 5 | 69.86 | 12.90 | 8.51 | 3.38 | 0.12 | 1.95 | 0.071 | 1.41 | 0.037 |

| 6 | 69.79 | 12.91 | 8.52 | 3.35 | 0.12 | 1.96 | 0.072 | 1.41 | 0.037 |

| 7 | 69.83 | 12.83 | 8.51 | 3.36 | 0.12 | 1.96 | 0.071 | 1.41 | 0.041 |

| 8 | 69.85 | 12.82 | 8.52 | 3.34 | 0.12 | 1.96 | 0.072 | 1.40 | 0.037 |

| 9 | 69.85 | 12.95 | 8.52 | 3.37 | 0.13 | 1.96 | 0.071 | 1.40 | 0.038 |

| 10 | 69.86 | 12.79 | 8.52 | 3.39 | 0.12 | 1.95 | 0.071 | 1.41 | 0.040 |

| Average | 69.84 | 12.87 | 8.51 | 3.36 | 0.12 | 1.96 | 0.071 | 1.41 | 0.038 |

| Maximum | 69.86 | 12.95 | 8.52 | 3.39 | 0.13 | 1.96 | 0.072 | 1.41 | 0.041 |

| Minimum | 69.79 | 12.79 | 8.50 | 3.33 | 0.12 | 1.95 | 0.070 | 1.40 | 0.037 |

| Range | 0.07 | 0.16 | 0.02 | 0.06 | 0.01 | 0.01 | 0.002 | 0.01 | 0.004 |

| Standard deviation | 0.021 | 0.054 | 0.007 | 0.018 | 0.002 | 0.004 | 0.001 | 0.004 | 0.001 |

| RSD % | 0.03 | 0.42 | 0.08 | 0.53 | 1.34 | 0.22 | 0.80 | 0.28 | 3.90 |

* : Quantitative results of TiO₂ are out of calibration range.

Conclusions

The results show that high precision analysis of elements in soda-lime glass can be performed using the benchtop WDXRF spectrometer Supermini200. The calibration curves obtained using the theoretical alpha corrections show good correlation for both major and trace components.

Supermini200 is a benchtop spectrometer with a small footprint and is able to be operated with only a wall power outlet. Since Supermini200 is not site-specific, it has the great advantage that it can be installed anywhere, and is therefore particularly matched for small laboratories and beside production area.