Application Note WDXRF1054

Introduction

Residual oil, which contains various elements such as S, Fe, Ni, V and others, is obtained after distilling crude oil and used for marine fuel or electric power plant fuel. When residual oil is burned, some elements can cause damage to marine engines and the environment. For example, sulfur is regarded to be the most harmful element causing air pollution, or metals like Ni, V and Fe are regarded as catalyst poison which blocks cata-lyst pour.

XRF is a powerful tool for analyzing these elements in residual oil. Sample preparation is very simple and analysis results are obtained quickly.

This application note demonstrates that ZSX Primus is compliant with IP610/13 for the analysis of S, Fe, Ni and V.

Instrument

The ZSX Primus, a tube-below sequential wavelength dispersive X-ray fluorescence (WDXRF) spectrometer, is optimized for routine analysis that today’s petroleum laboratories need to perform. The optical chamber can be maintained under vacuum while only the sample chamber is under helium atmosphere by using vacuum seal between optical chamber and sample chamber. The vacuum seal enable to minimize helium gas con-sumption and required time for helium purge. The spectrometer is equipped with a 3 kW X-ray tube. If higher sensitivity or precision is required, a 4 kW X-ray tube with ultra thin beryllium window is available.

The operation software is designed for easy routine analysis. The quantitative analysis flowbar guides users step by step to generate applications. The sample ID table and the program operation help operators carry out daily analysis.

Sample and sample preparation

Residual oil standard samples supplied by Analytical Services, Inc. were used for calibration.

Eight grams of each residual oil sample was poured into a liquid cell (Chemplex® 1095). 3.6 μm thickenss Mylar® (Chemplex® 150) was used as sample film.

Figure 1: Oil sample cell

Measurement and calibration

Measurements were performed on the ZSX Primus with a high-performance 4 kW Rh-target X-ray tube for S, Fe, Ni and V. A primary beam Al filter was used to protect the X-ray tube window in case of sample leakage. In addition, the filter reduces the background to improve the peak to background ratio. Measurement conditions are shown in Table 1.

Table 1: Measurement conditions

| Element | S | Fe | Ni | V |

| Line | Kα | Kα | Kα | Kα |

| kV-mA | 50-50 | 50-50 | 50-50 | 50-50 |

| Primary Filter | Be | Al-2 | Al-2 | Al-1 |

| Slit | S4 | S2 | S2 | S2 |

| Crystal | Ge | LiF | LiF | LiF |

| Detector | PC | SC | SC | SC |

| Time Peak(s) | 20 | 20 | 20 | 20 |

| BG(s) | 10x2 | 10x2 | 10x2 | 10x2 |

The calibration curves were generated with matrix correction applied to all the analytes. The correction coefficients used were calculated theoretically by the fundamental parameter (FP) method. The calibration results are listed in Table 2 and the calibration curves are shown in Figure 2.

Table 2: Calibration results

| Element | unit | Calibration range | Accuracy |

| S | mass% | 0.165 – 5.51 | 0.014 |

| Fe | ppm | 13 – 504 | 8.1 |

| Ni | ppm | 2 – 101 | 1.0 |

| V | ppm | 2 – 150 | 5.8 |

Figure 2: Calibration curves for residual oil

The accuracy of linear calibration is calculated by the following formula:

$Accuracy = \sqrt{ \frac{\sum_i{(C_i-\hat{C}_i)^2}}{n-2} }$

$C_i$: calculated value of standard sample

$\hat{C}_i$: reference value of standard sample

n : number of standard samples.

Analysis results

Typical lower limit of detection (LLD) for Fe, Ni and V calculated using the standard sample with the low content by the following formula are shown in Table 3.

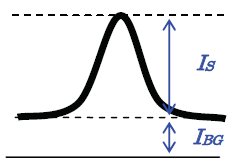

$LLD = 3 \cdot \frac{x}{I_s} \cdot \sqrt{\frac{2 \cdot I_{BG}}{1000 \cdot t}}$

$x$ : Standard value (ppm)

$t$ : Counting time (s)

$I_S$ : Net intensity (kcps)

$I_{BG}$ : Background intensity (kcps)

Figure 3: Net and background intensities

Table 3: LLDs of Fe, Ni and V (t = 100 s (unit: ppm)

| Element | LLD |

| Fe | 0.2 |

| Ni | 0.1 |

| V | 0.5 |

Repeatability tests for two samples (sample A and B) were carried out for 21 test portions according to “method A” of IP610-13. The test results are tabulated in Table 4, in which the difference of two successive aliquots are shown and “r” represents “repeatability” defined in IP 610/13, which states that the difference between two successive test results obtained by the same operator with the same apparatus under constant operation conditions on identical test material would, in the normal and correct operation of the test method, exceed the value in Table 5, which lists the repeatability (r) of each analyte, in only one case in twenty.

The test results shown in Table 4, where the difference of two successive aliquots does not exceed the repeatability (r) for each analyte, prove that the perfor-mance of the ZSX Primus meets the requirement of ISO610-13 for S, Fe, Ni and V analysis.

Table 4: Repeatability test results (A) Sample A

| S* | Fe | Ni | V | |||||

| mass% | ppm | ppm | ppm | |||||

| Result | Diff. | Result | Diff. | Result | Diff. | Result | Diff. | |

| 1 | 0.170 | 12.9 | 49.3 | 259.8 | ||||

| 2 | 0.169 | 0.000 | 14.5 | 1.6 | 49.8 | 0.5 | 257.2 | 2.5 |

| 3 | 0.169 | 0.000 | 14.5 | 0.0 | 49.4 | 0.4 | 258.7 | 1.5 |

| 4 | 0.170 | 0.001 | 13.5 | 1.0 | 49.5 | 0.1 | 260.4 | 1.7 |

| 5 | 0.171 | 0.001 | 12.7 | 0.8 | 49.0 | 0.5 | 259.2 | 1.2 |

| 6 | 0.170 | 0.001 | 13.8 | 1.1 | 49.5 | 0.5 | 260.5 | 1.3 |

| 7 | 0.170 | 0.001 | 13.8 | 0.1 | 49.7 | 0.2 | 261.5 | 1.0 |

| 8 | 0.170 | 0.000 | 13.6 | 0.2 | 49.4 | 0.3 | 258.5 | 3.0 |

| 9 | 0.170 | 0.000 | 14.0 | 0.4 | 49.4 | 0.0 | 259.2 | 0.7 |

| 10 | 0.170 | 0.001 | 13.6 | 0.4 | 49.8 | 0.5 | 262.0 | 2.8 |

| 11 | 0.172 | 0.002 | 13.5 | 0.1 | 50.1 | 0.3 | 259.2 | 2.9 |

| 12 | 0.171 | 0.001 | 13.4 | 0.1 | 50.1 | 0.0 | 261.9 | 2.7 |

| 13 | 0.170 | 0.001 | 13.7 | 0.3 | 50.0 | 0.1 | 261.9 | 0.0 |

| 14 | 0.170 | 0.000 | 13.0 | 0.7 | 49.8 | 0.2 | 257.7 | 4.2 |

| 15 | 0.171 | 0.001 | 13.9 | 0.9 | 49.9 | 0.1 | 259.6 | 1.9 |

| 16 | 0.171 | 0.000 | 12.6 | 1.2 | 49.6 | 0.2 | 258.9 | 0.6 |

| 17 | 0.171 | 0.000 | 13.8 | 1.1 | 50.6 | 0.9 | 261.2 | 2.3 |

| 18 | 0.170 | 0.001 | 14.1 | 0.3 | 49.8 | 0.8 | 263.3 | 2.0 |

| 19 | 0.171 | 0.001 | 13.8 | 0.3 | 50.2 | 0.4 | 262.4 | 0.8 |

| 20 | 0.170 | 0.001 | 13.9 | 0.0 | 50.1 | 0.1 | 260.5 | 1.9 |

| 21 | 0.170 | 0.001 | 13.6 | 0.3 | 50.0 | 0.1 | 259.8 | 0.8 |

| Max. | 0.002 | 1.6 | 0.9 | 4.2 | ||||

| r | 0.028 | 5.1 | 2.3 | 9.3 | ||||

(B) Sample B

| S | Fe | Ni | V | |||||

| mass% | ppm | ppm | ppm | |||||

| Result | Diff. | Result | Diff. | Result | Diff. | Result | Diff. | |

| 1 | 2.01 | 203.6 | 39.5 | 117.9 | ||||

| 2 | 2.02 | 0.00 | 206.7 | 3.1 | 39.9 | 0.4 | 119.1 | 1.2 |

| 3 | 2.01 | 0.01 | 207.3 | 0.7 | 39.6 | 0.3 | 118.4 | 0.7 |

| 4 | 2.03 | 0.02 | 206.9 | 0.5 | 39.4 | 0.1 | 118.0 | 0.3 |

| 5 | 2.00 | 0.03 | 207.5 | 0.6 | 39.2 | 0.3 | 118.0 | 0.0 |

| 6 | 1.99 | 0.01 | 204.1 | 3.4 | 39.3 | 0.1 | 115.8 | 2.2 |

| 7 | 2.01 | 0.02 | 206.0 | 1.9 | 39.6 | 0.4 | 118.4 | 2.6 |

| 8 | 2.00 | 0.01 | 206.9 | 0.9 | 39.6 | 0.0 | 118.3 | 0.2 |

| 9 | 2.00 | 0.01 | 206.5 | 0.4 | 39.6 | 0.1 | 116.4 | 1.9 |

| 10 | 1.98 | 0.02 | 207.2 | 0.7 | 39.2 | 0.4 | 116.8 | 0.4 |

| 11 | 1.99 | 0.01 | 203.4 | 3.8 | 39.2 | 0.1 | 118.0 | 1.2 |

| 12 | 2.00 | 0.01 | 207.6 | 4.3 | 39.7 | 0.4 | 116.7 | 1.3 |

| 13 | 2.00 | 0.00 | 207.1 | 0.5 | 39.6 | 0.1 | 117.2 | 0.6 |

| 14 | 1.99 | 0.01 | 205.0 | 2.1 | 39.6 | 0.0 | 117.7 | 0.5 |

| 15 | 1.99 | 0.00 | 206.1 | 1.1 | 40.0 | 0.4 | 117.9 | 0.2 |

| 16 | 1.99 | 0.00 | 205.0 | 1.1 | 40.0 | 0.0 | 117.9 | 0.0 |

| 17 | 1.99 | 0.00 | 205.6 | 0.6 | 39.7 | 0.3 | 117.1 | 0.7 |

| 18 | 1.98 | 0.01 | 204.4 | 1.3 | 39.2 | 0.5 | 117.3 | 0.1 |

| 19 | 1.98 | 0.01 | 206.4 | 2.0 | 39.9 | 0.7 | 119.3 | 2.0 |

| 20 | 1.99 | 0.00 | 206.7 | 0.3 | 39.8 | 0.1 | 117.5 | 1.8 |

| 21 | 1.99 | 0.00 | 206.2 | 0.5 | 39.7 | 0.1 | 118.5 | 1.0 |

| Max. | 0.03 | 4.3 | 0.7 | 2.6 | ||||

| r | 0.33 | 23.5 | 1.9 | 4.4 | ||||

Table 5: Repeatability defined in IP 610/13 METHOD A

| Element | Concentration range | Repeatability [ r ] |

| S | 0.9274 mass% – 3.4015 mass% | 0.1632 X |

| Fe | 8.5 ppm – 243.7 ppm | 0.09563 (X+40) |

| Ni | 2.3 ppm – 86.3 ppm | 0.03231 (X+20) |

| V | 12.4 ppm – 363.9 ppm | 0.03455 (X+10) |

Conclusions

Routine analysis of residual oil with high accuracy and precision can be easily performed on the ZSX Primus. This application note demonstrates that the performance of the ZSX Primus meets the requirement of IP 610/13 for the analysis of S, Fe, Ni and V.

Reference

IP 610/13 ; Determination of sulfur, vanadium, nickel, iron, calcium, zinc and phosphorous in residual fuel oil by wavelength dispersive X-ray fluorescence spectrometry