Application Note WDXRF1005

Introduction

Cement is one of the most important materials for construction. Many kinds of hydraulic cements, including Portland cement, with various physical properties are produced by changing the composition of clinker minerals; therefore, it is important to control the chemical composition of cement products and interim products.

ASTM C114-11 covers chemical analysis of hydraulic cement. In this standard, procedures of wet chemical analysis are mainly described and X-ray fluorescence (XRF) spectrometry is mentioned as example of “Rapid Test Methods”. In practice, XRF spectrometry has been used for chemical composition analysis of cement owing to its simple sample preparation and high precision.

This application note demonstrates quantitative analysis for Portland cement by the pressed pellet method according to ASTM C114-11 on Rigaku ZSX Primus III+, a sequential wavelength dispersive XRF spectrometer.

ASTM C114-11 and calibration standard

The standard ASTM C114-11 has the following descriptions about “Rapid Test Method”:

• Using the test method chosen, make single determinations for each analyte under consideration on at least seven CRM (Certified Reference Material) samples. Complete two rounds of tests on different days repeating all steps of sample preparations. Calculate the differences between values and aver-ages of the values from the two rounds of tests.

• When seven CRMs are used in the qualification procedures, at least six of the seven differences between duplicates obtained of any single analytes shall not exceed the limits shown in Table 1 and the remaining differences by no more than twice that value.

• For each analyte and each CRM, the average obtained shall be compared to the certified concentrations. When seven CRMs are used in the qualification procedure, at least six of the seven averages for each analytes shall not differ from the certified concentrations by more than the value shown in Table 1, and the remaining average by more than twice that value.

The maximum permissible variations in analysis results defined in ASTM C114-11 are listed in Table 1.

Table 1: Maximium permissible variation (in mass%)

| Analyte | Maximum difference between duplicates | Maximum difference of the average of duplicates from the certificate values |

| SiO₂ | 0.16 | ±0.2 |

| Al₂O₃ | 0.20 | ±0.2 |

| Fe₂O₃ | 0.10 | ±0.10 |

| CaO | 0.20 | ±0.3 |

| MgO | 0.16 | ±0.2 |

| SO₃ | 0.10 | ±0.1 |

| Na₂O | 0.03 | ±0.05 |

| K₂O | 0.03 | ±0.05 |

| TiO₂ | 0.02 | ±0.03 |

| P₂O₅ | 0.03 | ±0.03 |

| ZnO | 0.03 | ±0.03 |

| Mn₂O₃ | 0.03 | ±0.03 |

| Cl | 0.003 | N/A |

ASTM C114-11 directs that acceptable reference cements are NIST CRMs, or other reference cements traceable to the NIST CRMs.

In this application note, seven NIST CRMs (SRM1881a, 1884a, 1885a, 1886a, 1887a, 1888a and 1889a) were used for calibration and a qualification test.

Instrument

The ZSX Primus III+, a tube-above sequential wavelength dispersive X-ray fluorescence (WDXRF) spectrometer, is optimized for routine analyses in powder sample analysis.

The tube-above optics, the programmable, changeable vacuum speed and the powder trap of the ZSX Primus III+ enable secure analysis of powder samples and low frequency of maintenance by preventing pressed pellet specimens from breaking and falling and by protecting the vacuum pump and magnetic valves from fine particles scattered from specimens.

The ZSX Primus III+ has a pre-evacuation chamber. A specimen is evacuated in this chamber and then is transported on the measurement position. During the measurement, the next specimen to be analyzed can be loaded into the pre-evacuation chamber and waiting, which reduces the loading time. In addition, if a pressed pellet specimen should be broken because of vacuum, it happens inside the pre-evacuation chamber and the optical main chamber is not contaminated.

The system software is designed for ease of use in routine analyses. The Flowbar in quantitative analysis guides users in establishing calibration. The Easy Analysis and the Program Operation help operators carry out daily analysis easily and smoothly

Sample preparation

Cement powder samples were pulverized in a tungsten carbide container with n-hexane (the wet grinding method) for three minutes. Then, 4.5 grams of the resultant powders, pre-dried, were pressed at 150 kN. The wet grinding method prevents samples from sticking on the wall of the container and avoids intersample contamination, even after cleaning the container briefly (Figure 1).

Figure 1: Comparison of the condition in the container after pulverizing.

Measurement and calibration

Measurements were performed on the ZSX Primus III+ with a 3 kW Rh-target X-ray tube for the components listed in Table 1. Measurement condition is shown in Table 2. The total counting time is less than 5 minutes.

The RX25 multilayer analyzing crystal, included in the standard configuration, has high sensitivity for Mg and Na and is capable of reducing interference from higher-order lines, such as Ca-Kα-3rd, which would interfere with Mg-Kα.

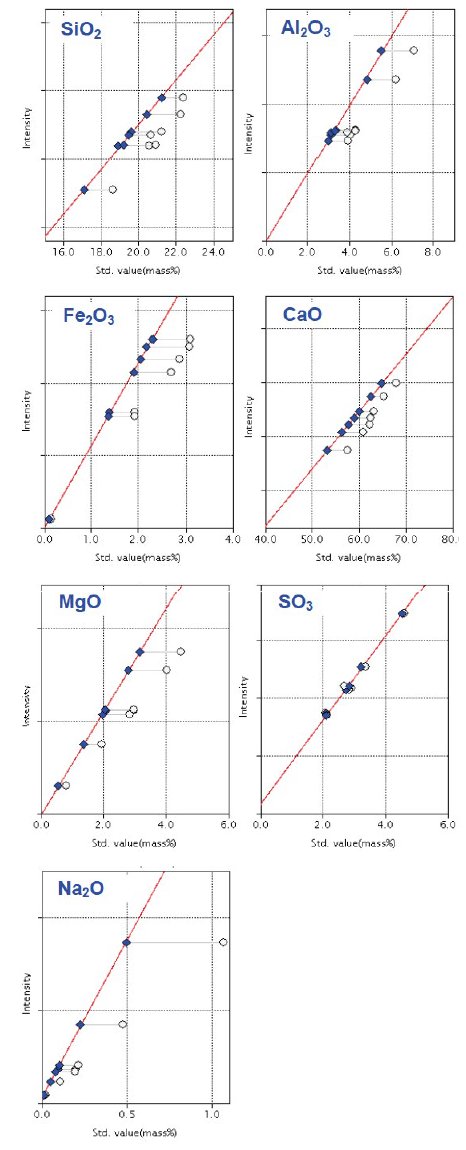

The calibration curves were generated with theoretical alphas (matrix correction coefficients calculated theoretically by the fundamental parameter method) for all the analytes. The calibration curves for the representative analytes are shown in Figure 2.

Qualification test for ASTM C114-11

A qualification test for “Rapid Test Method” in ASTM C114-11 was carried out.

Pressed pellet specimens for the seven NIST CRMs were prepared and quantified with the calibration previously established. In a different day, the same procedure was repeated. The test results are summarized in Table 3, which shows only the maximum values for both the differences between the duplicates and the differences of the averages of the duplicates from the certificate values.

The qualification test results shown in Table 3 prove that the analysis method demonstrated in this application note meets the requirements described in ASTM C114-11.

Repeatability test

The specimens of NIST SRM1889a prepared for the qualification test were measured consecutively ten times. This repeatability test results are summarized in Table 4. It shows the averages and the standard deviations of the ten-time measurement results for each specimen, together with the limits of the qualification test for ASTM C114-11 for reference. As shown in the Table 4, the standard deviations obtained are much smaller than required, in comparison with the requirement in ASTM C114-11; therefore, much shorter counting time can be used to qualify the ASTM C144-11 standard when higher throughput is required.

Figure 2: Representative calibration curves for the analytes of cement. White circle: uncorrected point; Blue diamond: point with correction applied

Table 2: Measurement condition

| Path atmosphere | Vacuum |

| Tube condition | 50 kV and 50 mA |

| Analysis area | 30 mm in diameter |

| Element | Si | Al | Fe | Ca | Mg | S | Na |

| Line | Kα | Kα | Kα | Kα | Kα | Kα | Kα |

| Attenuator | 1/1 | 1/1 | 1/1 | 1/10 | 1/1 | 1/1 | 1/1 |

| Slit | S4 | S4 | S2 | S4 | S4 | S4 | S4 |

| Crystal | PET | PET | LiF | LiF | RX25 | PET | RX25 |

| Detector | PC | PC | SC | PC | PC | PC | PC |

| Element | K | Ti | P | Zn | Mn | CI | |

| Line | Kα | Kα | Kα | Kα | Kα | Kα | |

| Attenuator | 1/1 | 1/1 | 1/1 | 1/1 | 1/1 | 1/1 | |

| Slit | S4 | S2 | S4 | S2 | S2 S | 2 | |

| Crystal | LiF | LiF | PET | LiF | LiF | PET |

Table 3: Qualification test result (unit: mass%)

| Analyte | Calibration range | Calibration range | Difference of the average of duplicate from the certificate values | ||

| Limit | Result* | Limit | Result* | ||

| SiO₂ | 18.637 – 22.38 | 0.16 | 0.10 | 0.2 | 0.2 |

| Al₂O₃ | 3.85 – 7.06 | 0.20 | 0.04 | 0.2 | 0.1 |

| Fe₂O₃ | 0.152 – 3.09 | 0.10 | 0.003 | 0.10 | 0.04 |

| CaO | 57.58 – 67.87 | 0.20 | 0.12 | 0.3 | 0.1 |

| MgO | 0.814 – 4.475 | 0.16 | 0.04 | 0.2 | 0.1 |

| SO₃ | 2.086 – 4.622 | 0.10 | 0.05 | 0.1 | 0.1 |

| Na₂O | 0.021 – 1.068 | 0.03 | 0.02 | 0.05 | 0.01 |

| K₂O | 0.093 – 1.228 | 0.03 | 0.003 | 0.05 | 0.01 |

| TiO₂ | 0.084 – 0.366 | 0.02 | 0.01 | 0.03 | 0.01 |

| P₂O₅ | 0.022 – 0.306 | 0.03 | 0.01 | 0.03 | 0.004 |

| ZnO | 0.001 – 0.107 | 0.03 | 0.001 | 0.03 | 0.002 |

| Mn₂O₃ | 0.007 – 0.259 | 0.03 | 0.001 | 0.03 | 0.002 |

| Cl | 0.0019 – 0.013 | 0.003 | 0.005** | N/A*** | 0.006 |

** The maximum difference for Cl is 0.005 mass%, which exceeds the limit 0.003 mass% while the differences of all the other CRMs are less than 0.003 mass%. The value 0.005 mass% is less than the double of the limit, 0.006 mass%.

*** No value is given.

Table 4: Repeatability test result using SRM1889A

| Analyte | Certified value | Ten-time measurement result | Maximum difference of averages between duplicates | Maximum difference of the average of duplicate from the certificate values | |||

| 1st specimen | 2nd specimen | ||||||

| Average | Std. dev. | Average | Std. dev. | ||||

| SiO₂ | 20.66 | 20.74 | 0.040 | 20.78 | 0.024 | 0.16 | 0.2 |

| Al₂O₃ | 3.89 | 3.85 | 0.008 | 3.86 | 0.005 | 0.20 | 0.2 |

| Fe₂O₃ | 1.937 | 1.912 | 0.0026 | 1.910 | 0.0019 | 0.10 | 0.10 |

| CaO | 65.34 | 65.41 | 0.048 | 65.42 | 0.031 | 0.20 | 0.3 |

| MgO | 0.814 | 0.864 | 0.0031 | 0.864 | 0.0027 | 0.16 | 0.2 |

| SO₃ | 2.69 | 2.68 | 0.006 | 2.69 | 0.002 | 0.10 | 0.1 |

| Na₂O | 0.195 | 0.201 | 0.0022 | 0.199 | 0.0025 | 0.03 | 0.05 |

| K₂O | 0.605 | 0.610 | 0.0010 | 0.612 | 0.0008 | 0.03 | 0.05 |

| TiO₂ | 0.227 | 0.225 | 0.0012 | 0.223 | 0.0013 | 0.02 | 0.03 |

| P₂O₅ | 0.11 | 0.11 | 0.002 | 0.11 | 0.002 | 0.03 | 0.03 |

| ZnO | 0.0048 | 0.0042 | 0.0001 | 0.0040 | 0.0001 | 0.03 | 0.03 |

| Mn₂O₃ | 0.2588 | 0.259 | 0.0005 | 0.259 | 0.0009 | 0.03 | 0.03 |

| Cl | 0.0019 | 0.0030 | 0.0001 | 0.0020 | 0.0001 | 0.003 | N/A |

Conclusions

Hydraulic cement samples can be routinely analyzed with high accuracy and precision on the ZSX PrimusIII+ by the pressed pellet method, simple sample preparation.

The ZSX PrimusIII+ is suitable for powder sample analysis owing to its tube-above optics and functions for measuring pressed pellet specimens securely.

The qualification test for “Rapid Test Methods” described in ASTM C114-11 demonstrated in this application note proves that the combination of the performance of the ZSX Primus III+ and the wet grinding followed by pressing pulverized powder samples meets the requirements defined in ASTM C114-11.

Reference

ASTM C114-11 Standard Test Methods for Chemical Analysis of Hydraulic Cement