Precious Metal Recovery in Used Catalytic Converters

Recovering platinum, palladium, and rhodium from used automotive catalytic converters presents a lucrative opportunity within the recycling sector. EDXRF provides rapid elemental analysis, which is essential for valuation purposes.

Typically, the honeycomb cores are removed from used catalytic converters and ground into fine powder. This powder contains a complex mix of elements, including precious metals, which can be extracted or sold. Regardless of varying matrix compositions, our EDXRF instruments help you assess the concentration of precious metals without requiring a large suite of calibration standards.

Learn more about how our EDXRF solutions can enhance your precious metal recovery operations.

Why choose EDXRF for precious metals analysis?

Automotive catalyst recycling Benchtop solutions

We offer benchtop solutions for optimizing precious metal recovery operations. Here are some advantages of using our EDXRF systems:

- Simple, fast, and non-destructive

Our analyzers provide easy operation, even for non-technical personnel, and sample preparation is simple and straightforward. You get results in minutes without destroying your samples.

- Cost-effective solution

EDXRF analyzers offer you a cost-effective solution, especially when compared to other techniques. Generally, they are more affordable upfront and have lower operating costs over the lifetime of the instrument. Our benchtops are self-installed and maintained.

- Reliable results

EDXRF is a powerful tool for assessing the precious metal content of powdered catalytic converter cores. With RPF-SQX Fundamental Parameters (FP) software, you can analyze these diverse compositions without needing a large suite of calibration standards. Additionally, user-defined Matching Libraries allow you to achieve greater accuracy by tailoring methods to your specific materials.

- Auto Cats starter library

We offer an Auto Cats starter library calibrated with fire-assayed samples, which you can expand or customize to accommodate various catalytic materials or families. This flexibility ensures precise alignment between theoretical and measured intensities, enabling more reliable results for diverse compositions.

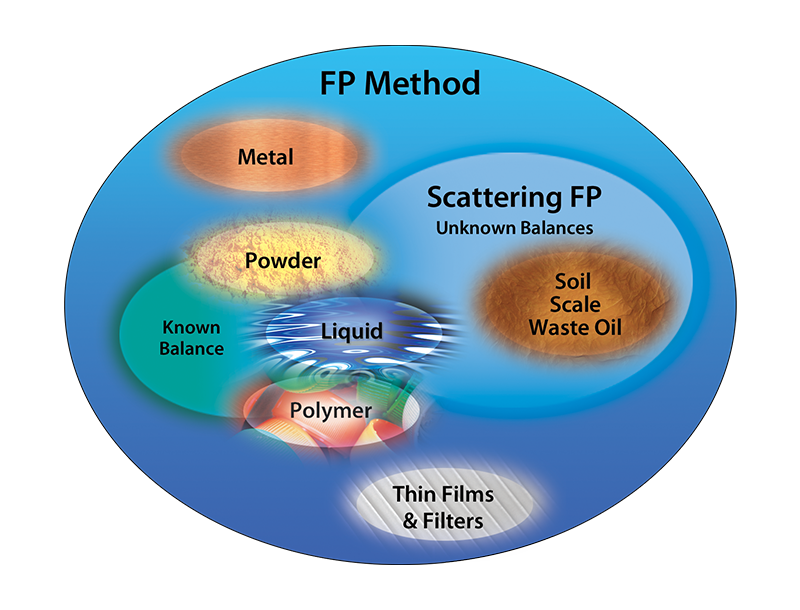

Advanced Fundamental Parameters software

Advanced qualitative and quantitative analysis is powered by our RPF-SQX FP software, featuring Rigaku Profile Fitting (RPF) technology and Scattering FP. This software allows semi-quantitative analysis of almost all sample types without standards and rigorous quantitative analysis with standards. Scattering FP automatically estimates the concentration of unmeasurable low atomic number elements (hydrogen to fluorine) and provides appropriate corrections.

Given at least one sample with known concentrations from a referee technique, the software allows you to quickly and easily create a Matching Library. This feature changes the analysis from semi-quant to fully quantitative, tuning your XRF to your specific analysis needs.

Calibration standards can be expensive and difficult to obtain for newly developed materials. With RPF-SQX, the number of required standards is greatly reduced. This option significantly lowers the cost of ownership and reduces your workload requirements.

Application examples

Explore our application examples to see if our solutions can benefit your needs

Recommended products

Solutions for precious metal recovery in used catalytic converters

For routine analysis NEX QC+ QuantEZ

Recommended when you need a quick, cost-effective solution for routine quality control or quality assurance. This system is packaged with QuantEZ software, which simplifies operations and provides a flow bar interface for creating custom methods. RPF-SQX Fundamental Parameters with Rigaku Profile Fitting is also available with this system, enabling semi-quantitative measurement without needing a large suite of calibration standards.

For complex applications NEX CG II Series

Recommended when you require higher power and increased sensitivity. These systems are ideal for ultra-low and trace-level performance, such as processing precious metals. The RPF-SQX Fundamental Parameters software, featuring Rigaku Profile Fitting technology and Scattering FP, is also available with these systems.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.