Silicone Coatings Analysis

Insufficient or excessive silicone application on paper and plastic substrates can significantly alter the release characteristics of a product, such as labels or packaging. EDXRF is a widely used technique for analyzing silicone coatings because it offers a fast, simple, and cost-effective way to measure silicone coat weight in just seconds. It helps manufacturers ensure consistent product quality, minimize waste, and optimize production processes.

Whether you are in packaging, labeling, or any other industry using silicone coatings, EDXRF can be invaluable for quality control and process improvement. With its ease of use, affordability, and ability to handle even very low silicone coating weights, EDXRF is an attractive choice for businesses of all sizes.

Learn more about our at-line and in-line solutions for determining silicone coating thicknesses or coat weight or the elemental composition of a product.

Why choose EDXRF for silicone coat weight analysis?

EDXRF provides total quality control solutions

EDXRF, a type of XRF (X-ray fluorescence), has long been a familiar technology for release coatings, converters, vacuum-formed plastics manufacturers, and other industries using silicone oils as barrier layers, release coatings, or denesting agents.

- Total quality control solution for silicone coaters

- Silicone analysis on paper, clay-coated paper, and thin film release liners

- Proprietary silicone on clay-coated paper algorithms

- Specialty films — moisture and air barriers, including high-barrier packaging films

- Printed, metalized, and non-metalized

- Converters – silicone on plastic or paper

- Vacuum-formed plastics – denesting silicone coatings

At-line solutions

For quick at-line analysis, we offer NEX QC Series benchtop analyzers for measuring very low silicone coating weights and metal catalysts in silicone coatings. These systems are compact, do not require an external computer, and are self-maintained. They are a cost-effective solution and provide:

- Rapid silicone coating thickness and composition

- Ultra-low silicone coating weights

- Measurement of Sn, Bi, Ti, Pt, etc., in metal-catalyzed silicone release coatings

- Silicone determination without helium or special sample cups

- Easy sample prep by simply placing a test coupon in the analysis chamber

- Simple, easy operation and built-in printer for convenience

- Dynamic corrections for mineralogy variations in the substrate eliminate the need for taring and improve measurement accuracy

_picture_2024.11.07.png)

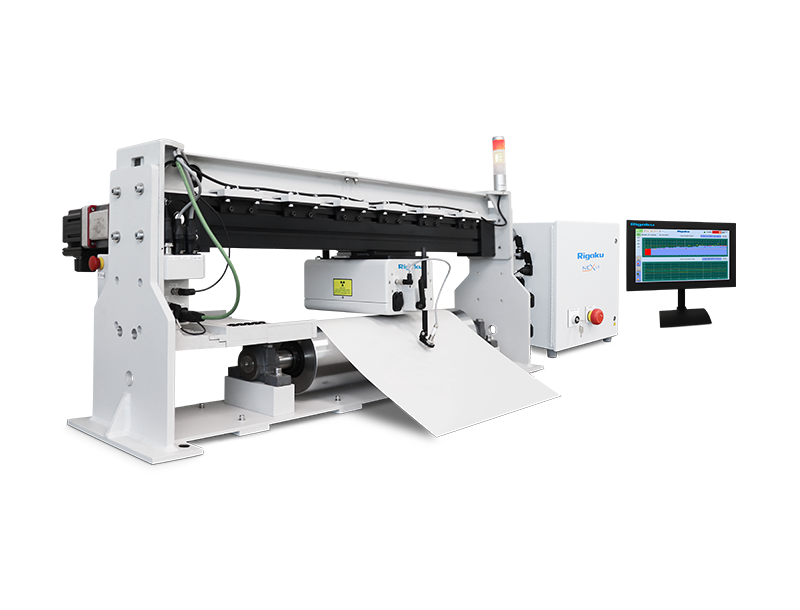

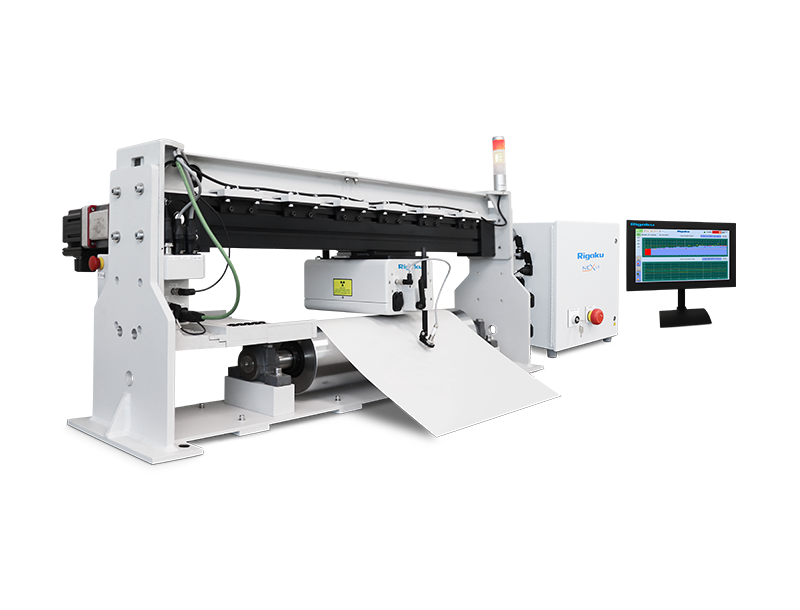

In-line solutions

NEX LS provides an in-line solution for silicone coat weight profiling for roll-to-roll (R2R) applications. This system offers a detailed visualization of your entire coating process, allowing for immediate quality control decisions and process adjustments without stopping production. It provides:

- Continuous monitoring and control, reducing at-line checks

- Cross-direction and machine-direction data for the entire roll

- Immediate defect detection as the roll is being produced

- Roll reporting and data logging for traceability and audits

- Easy automatic calibration and operation

- Measurement capability for web widths up to 2365 mm

- Dynamic corrections for mineralogy variations in the substrate eliminate the need for taring and improve measurement accuracy

- Consistent performance, regardless of substrate color or composition variations (e.g., clay-coated paper)

See NEX LS in action

How does NEX LS work?

NEX LS features EDXRF technology, a non-destructive technique that offers valuable information about the material or products as they are being produced. NEX LS serves web applications by performing real-time silicone coat weight analysis.

The measuring head, mounted on a rigid beam, is equipped with a linear traversing mechanism ensuring constant head-to-surface distance. Where needed, the elemental composition of a coating is measured directly. In contrast, coat weight (or coating thickness) may be measured directly (where the counting rate for an element is proportional to thickness) or indirectly by measuring attenuation of some substrate element (where the counting rate is negatively correlated to thickness).

When the analytical head sweeps back and forth across a moving web, source X-rays enter the product, exciting atoms in the material. The elements in the coating excite and fluoresce characteristic X-rays back to the detector. Users can choose full scanning mode or fixed analysis positions. The scanner transmits these measurements to a console box and industrial touchscreen computer, and real-time data displays as a graphical cross-direction and machine-direction profile.

Full scanning analysis

Fixed analysis solutions

Application examples

Explore our application examples for silicone coatings.

Recommended products

Solutions for silicone coatings analysis

For quick at-line checks NEX QC Series

Recommended when you need an affordable system for measuring silicone coating thickness and composition. NEX QC and NEX QC+ feature touchscreen operation and built-in printers for added convenience. No external computer is required.

_picture_2020.07.07.png)

For in-line analysis NEX LS

Recommended for continuous monitoring and control for roll-to-roll applications. This in-line EDXRF system provides valuable information about the coating’s properties or the product’s composition without stopping production. It provides real-time defect detection and lets you make immediate quality control decisions.

Information and resources

- Association of Independent Corrugated Converters (AICC)

- Association of Nonwoven Fabrics Industries (INDA)

- Association of Pulp & Paper Industry Chemists(ZELLCHEMING)

- Canadian Printing Industries Association

- China Technical Association of Paper Industry

- Confederation of European Paper Industry (Cepi)

- European Federation of Corrugated Board Manufacturers (FEFCO)

- European Federation of Multiwall Paper Sack Industry (EUROSAC)

- Fibre Box Association (FBA)

- Flexographic Technical Association (FTA)

- International Council of Forest & Paper Association (ICFPA)

- Japan Technical Association of Pulp & Paper Industry

- Japan Paper Association

- National Paper Trade Association (NPTA)

- Paperboard Packaging Council (PPC)

- Pulp and Paper Products Council (PPPC)

- Paper Shipping Sack Manufacturers’ Association

- Pulp & Paper Technical Association of Canada (PAPTAC)

- Pulp & Paper (resources site)

- Technical Association of Pulp & Paper Industry (TAPPI)

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.