Metals & Alloys

EDXRF is a powerful tool used for metals and alloys to ensure the integrity and quality of metal products. By utilizing EDXRF, you can precisely determine the elemental composition of metal and alloys to verify their classification or designation and control production processes. This non-destructive technique offers a fast and indispensable method for high-throughput quality control testing in the metals industry.

EDXRF analyzers are user-friendly and versatile, catering to both technical and non-technical operators. They provide a simple yet powerful and versatile solution for various applications, including screening, monitoring, and full characterization of metals and alloys.

Why choose EDXRF?

Versatility for identification, screening, and characterization of metals

Our benchtop EDXRF analyzers can be used for a broad range of applications, including:

- Elemental identification and classification of metals and alloys

- Monitoring and controlling production processes

- Verifying the designation of metal products

- Elemental analysis in foundries, smelters, mills, and other metal production settings

Other benefits

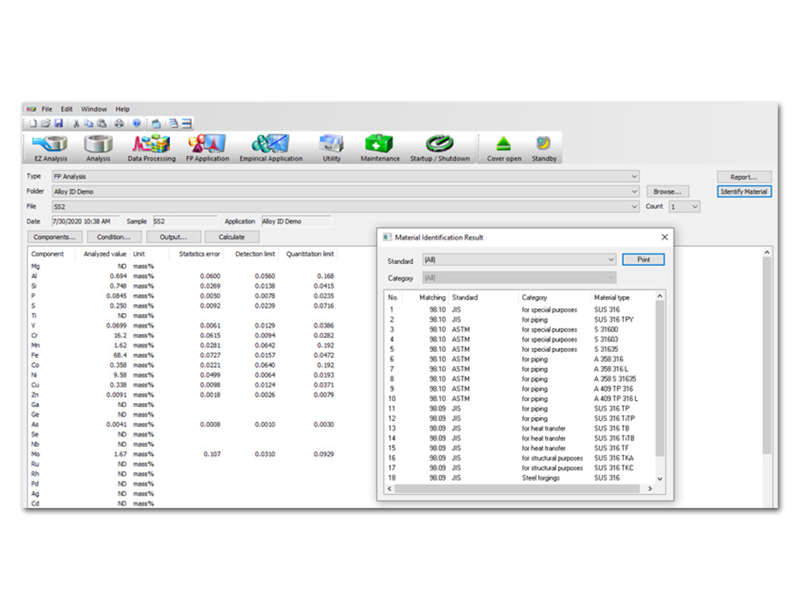

- Material Identification software

EDXRF provides material identification, also called positive material identification (PMI). Our Material Identification software includes standard ASTM and JIS alloy identification tables and allows you to create custom tables for your needs. This software is valuable for various applications, including quickly sorting unknown alloys.

- Non-destructive elemental analysis

EDXRF is non-destructive, allowing for the analysis of metals and alloys without altering or damaging the sample. This is particularly important for the quality control of finished products, as it allows for the analysis of samples without compromising their integrity. It also offers solutions for metal and conversion coatings.

- High-precision and quick results

Foundries, smelters, mills, and other facilities are characterized by continuous production, demanding day and night control of both the process and the quality of incoming and outgoing materials. EDXRF offers quick and high-quality results without complex setups or sample prep, making it ideal for high-throughput quality control testing.

- Minimized standards and cost

Rigaku EDXRF systems are available at every budget level, from entry-level to high-end performance. Options are also available for semi-quantitative measurement for screening, identification, and other semi-quant needs without needing a special reference library. With Rigaku’s RPF-SQX Fundamental Parameters (FP) software, the number of standards is greatly reduced, significantly lowering the cost of ownership. This software also offers user-definable Matching Libraries, providing an easy way to match your XRF to your specific analysis needs.

Application examples

Explore our application examples to see if our solutions can benefit your needs

Recommended products

Solutions for elemental analysis of metals and alloys

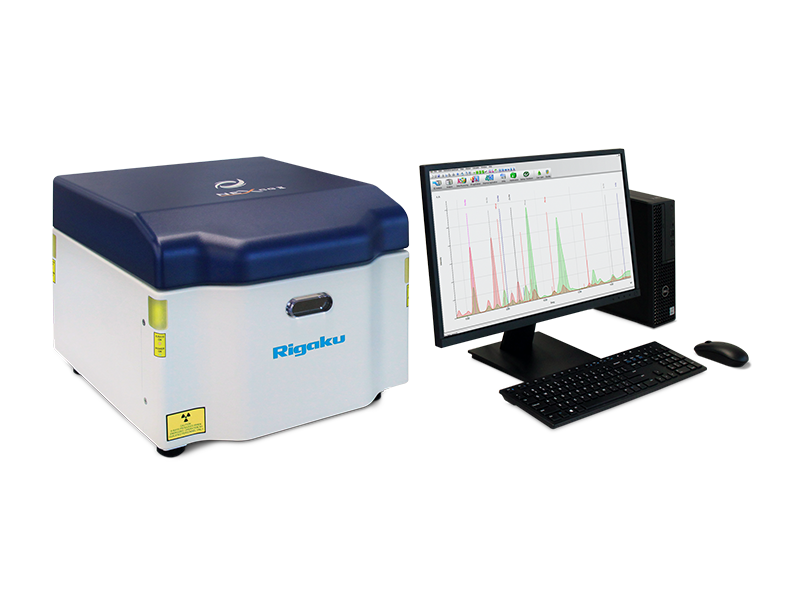

For routine analysis NEX QC+ QuantEZ

Recommended when you need a quick, cost-effective solution for routine quality control or quality assurance. This system is packaged with QuantEZ software, offering Fundamental Parameters for semi-quantitative measurement without needing a reference library.

For high-performance analysis NEX DE Series

Recommended when you need expanded capabilities, including higher sample batch throughput or small spot analysis like measuring plating on small parts. Whether your need is routine quality control or quality assurance, these systems provide quick elemental identification, screening, and characterization of metals and alloys. RPF-SQX Fundamental Parameters with Matching Libraries are also available with these systems.

_picture_29_2024.09.23.png)

For trace elemental analysis NEX CG II Series

Recommended when you need enhanced sensitivity. These systems are ideal for trace-level performance applications, such as processing precious metals. If desired, semi-quantitative analysis can be made using Rigaku RPF-SQX Fundamental Parameters without any assayed reference material for screening and characterization.

Information and resources

- American Institute of Mining, Metallurgical, and Petroleum Engineers (AIME)

- American Iron and Steel Institute (AISI)

- Metal Powder Industries Federation (MPIF)

- ASM International

- Australasian Institute of Mining and Metallurgy (AusIMM)

- Canadian Institute of Mining, Metallurgy and Petroleum (CIM)

- European Powder Metallurgy Association (EPMA)

- International Metallographic Society (IMS)

- Japan Powder Metallurgy Association (JPMA)

- Mining & Metallurgical Society of America (MMSA)

- National Institute of Standards and Technology (NIST)

- Society for Mining, Metallurgy & Exploration (SME)

- Wikipedia: Metallurgy

- Wikipedia: Alloy

- Wikipedia: Metal

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.