Metal and Conversion Coatings Analysis

EDXRF provides quick elemental analysis, allowing for rapid coating composition and thickness measurement of single- or multi-element metal coatings applied by chemical or electrochemical processes. For conversion coatings, EDXRF also allows you to measure plating thickness and monitor plating bath composition to ensure end-use specifications are met. Discover how our at-line and in-line EDXRF solutions can help you optimize your coating processes.

Looking for metal composition analysis solutions? Visit our Metals and Alloys page.

Why choose EDXRF?

Metalizing or applying metal coatings to the surface of objects is a technique used for various reasons. Whether you are enhancing durability, corrosion resistance, or weathering protection, monitoring the elemental composition and thickness of your metal coatings is critical. Over- or under-coating can compromise performance and lead to costly waste. EDXRF is a fast, non-destructive technique, which is important for quality control of finished products.

Benchtop solutions

Our benchtops are compact and user-maintained, offering a cost-effective way to measure and monitor metal coating thickness and composition. These advantages make them suitable for facilities with limited space or budget. Our range of at-line analyzers meets various needs:

- Single-layer coatings (one coating over a substrate, Zr, P, Zn, Ni, Cr, Cu, etc.)

- Binary alloy coatings

- Multilayer coatings (two or more layers over a substrate)

- Composite coatings over a substrate

- Elemental composition of plating baths

- Small spot analysis for quality control of small parts

For identification, screening, and characterization of metals, visit our Metals and Alloys page.

In-line solutions

Monitoring your processes in real time allows immediate defect detection without stopping production. We offer solutions for coil applications, providing valuable information about the coating’s properties or the product’s composition. Systems are also available for continuous monitoring of bath solutions. In-line EDXRF provides:

- Real-time process control

- Reduced downtime, minimizing at-line checks

- In-line quality control for metal coating thicknesses or composition

- On-line, multi-element analysis of plating bath composition

Application examples

Explore our application examples to see if our solutions can benefit your process and quality control needs.

Recommended products

Solutions for elemental analysis of metal and conversion coatings

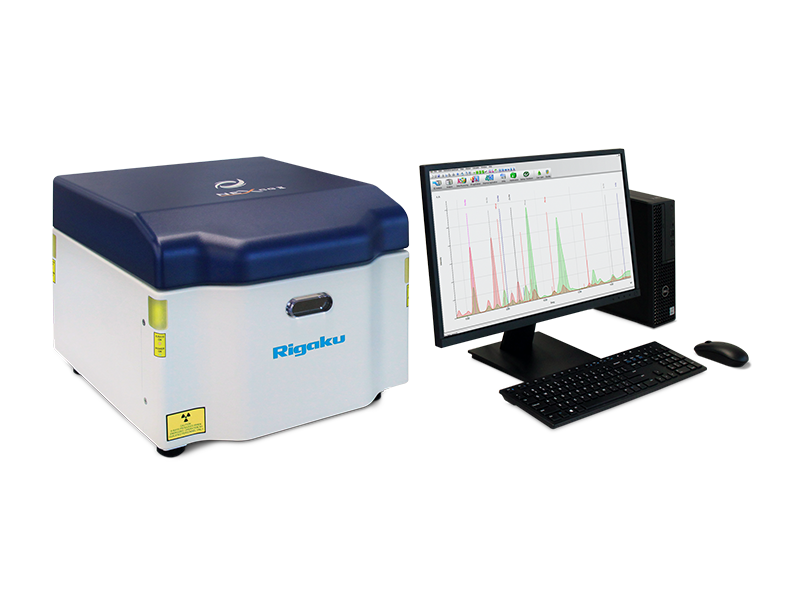

For quick at-line checks NEX QC Series

Recommended when you need an affordable system for routine quality control for coating thickness of conversion coatings, plating bath composition, and more. NEX QC and NEX QC+ feature touchscreen operation and built-in printers for added convenience. No external computer is required.

_picture_2020.06.25.png)

For high-performance analysis NEX DE Series

Recommended when you need expanded capabilities, including higher sample batch throughput and small spot analysis capabilities for measuring plating on small parts. Whether your need is basic quality control or quality assurance, these systems provide quick elemental identification, screening, and characterization of coatings, measuring plating on smaller pieces, or monitoring the elemental composition of your plating baths.

_picture_29_2024.09.23.png)

For complex applications NEX CG II Series

Recommended when you need to address multilayer coating applications. These analyzers feature a unique 3D Cartesian Geometry optical kernel that dramatically increases sensitivity, crucial for identifying the different elements present in each coating layer — even with complex multilayer coatings.

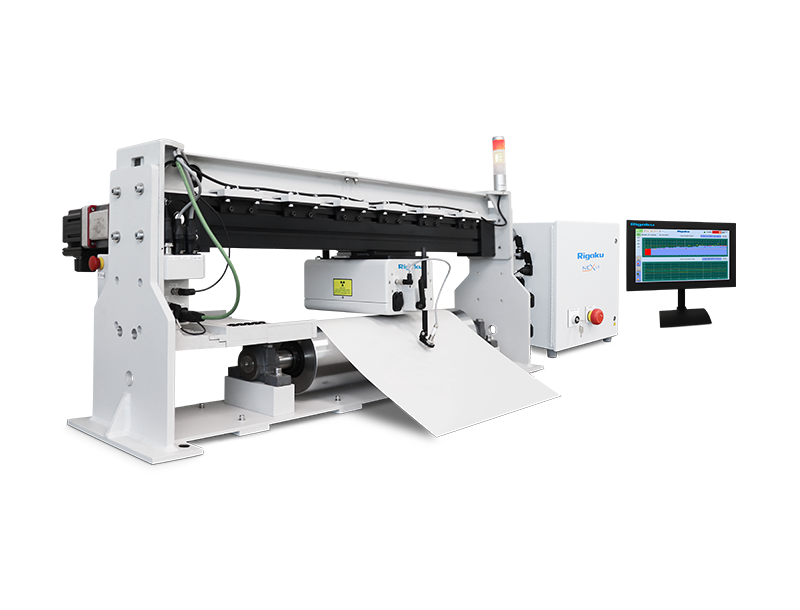

For in-line analysis NEX LS

Recommended for continuous monitoring and control for roll-to-roll applications. This multi-element coating analyzer is a compact, in-line EDXRF system that provides valuable information about the coating’s properties or the product’s composition without stopping production. It provides real-time defect detection and lets you make immediate quality control decisions.

For on-line control of plating baths NEX OL

Recommended when you need to maintain optimum conditions for plating bath solutions. NEX OL provides high-throughput manufacturers with a real-time analysis system for quantifying the elemental composition of plating baths, allowing for automated replenishing if desired.

Information and resources

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.