Semiconductors

EDXRF can be used to determine the thickness and elemental composition of multilayer thin films, as well as monitor waste streams. This is critical in semiconductor production, where the precise control of film properties is essential for optimal device performance. For waste streams, EDXRF enables efficient recovery of valuable metals, like copper, gold, silver, and other elements commonly used in semiconductor manufacturing, while also ensuring environmental compliance.

Unlike other analytical techniques, EDXRF provides a combination of speed, precision, and versatility for both waste stream monitoring and thin film analysis. Learn more about how our EDXRF benchtop solutions can help you.

Why choose EDXRF?

Benchtop solutions for multilayer thin film analysis

For thin film analysis, we offer NEX CG II Series benchtop analyzers for measuring thin films down to several atomic layers (less than 1 nm) and up to the µm or even mm range. These high-power systems provide:

- Film thickness and elemental composition for multilayers (9 to 10 layers)

- Measurement of film thicknesses, from a few atomic layers up to millimeters

- Rapid, non-destructive analysis of elements from sodium (Na) to uranium (U)

- Analysis without standards using RPF-SQX Fundamental Parameters

- Minimal sample preparation and no complex setups

- Powerful, easy-to-use software with multilingual user interface

- Low cost of ownership, self-installed and maintained

Benchtop solutions for waste stream monitoring

We offer a range of benchtops for waste stream monitoring and recovery processes. All systems provide elemental composition data in minutes and do not need ongoing allocations for expensive consumables and maintenance. Here are some advantages that our systems provide:

- Rapid, non-destructive elemental analysis, beneficial in fast-paced production settings

- Multi-element capabilities, from ultra-low concentrations to percent levels

- Measurement of all elements from sodium (Na) to uranium (U)

- Quantitative analysis without standards using RPF-SQX Fundamental Parameters

- Easy sample preparation and no complex setups

- Simple, easy operation, even for non-technical personnel

- Low cost of ownership, self-installed and maintained

Advanced Fundamental Parameters software

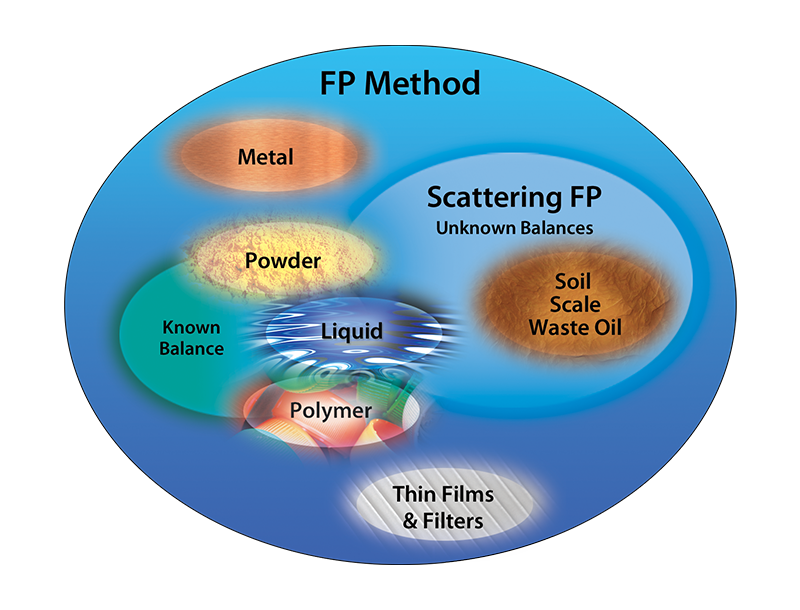

Advanced qualitative and quantitative analysis is powered by our RPF-SQX FP software, featuring Rigaku Profile Fitting (RPF) technology and Scattering FP. This software allows semi-quantitative analysis of almost all sample types without standards and rigorous quantitative analysis with standards. Scattering FP automatically estimates the concentration of unmeasurable low atomic number elements (hydrogen to fluorine) and provides appropriate corrections.

Given at least one sample with known concentrations from a referee technique, the software allows you to quickly and easily create a Matching Library. This feature changes the analysis from semi-quant to fully quantitative, tuning your XRF to your specific analysis needs.

Calibration standards can be expensive and difficult to obtain for newly developed materials. With RPF-SQX, the number of required standards is greatly reduced. This option significantly lowers the cost of ownership and reduces your workload requirements.

See NEX CG II Series analyzers in action

Recommended products

Solutions for semiconductor manufacturing and waste management

For routine analysis of waste streams NEX QC and NEX QC+

Recommended when you need an affordable system for identifying and quantifying the elemental composition of your samples. These systems feature touchscreen operation and built-in printers for added convenience. They have a small footprint and require no external computer, which is ideal for facilities limited in space.

_picture_2020.06.25.png)

For waste stream analysis using QuantEZ NEX QC+ QuantEZ

Recommended when you need a quick, cost-effective solution with a step up in performance. It includes all the features of the NEX QC Series models but is packaged with QuantEZ software. This software simplifies operations and provides a flow bar interface for creating custom methods. RPF-SQX Fundamental Parameters with Rigaku Profile Fitting is available with this system.

For high-performance and small spot analysis NEX DE Series

Recommended when you need expanded analytical capabilities, including higher sample batch throughput or small spot analysis. These systems provide quick elemental identification, screening, and characterization of your samples. RPF-SQX Fundamental Parameters featuring Rigaku Profile Fitting and Scattering FP are available with these systems.

_picture_127_2024.09.23.png)

For multilayer thin film analysis NEX CG II Series

Recommended when you need to determine the thickness and elemental composition of multilayer thin films. These analyzers feature a unique 3D Cartesian Geometry optical kernel that dramatically increases sensitivity, which is crucial for identifying the different elements present in each layer.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.