Application Note EDXRF1933

Scope

The analysis of palladium (Pd) in cellulose powder is demonstrated using NEX DE, which supports compliance with 21 CFR Part 11 regulations.

Background

Formulation process chemistry is an important part of the development cycle

of pharmaceuticals, from the identification and discovery phases to the clinical

trials and manufacturing. The formulation steps determine how to scale up

production from R&D phases to full-scale manufacturing. Critical steps in process

chemistry include the analysis of catalyst residue such as Pd and initial screening

for heavy metals, most importantly Cd. To meet vital analysis needs, Applied Rigaku

Technologies offers the NEX DE benchtop EDXRF analyzer.

For quality control, process chemistry, and manufacturing purposes, the Rigaku NEX

DE is an excellent tool for measuring catalyst residue, trace heavy elements, and

other elements of interest in pharmaceutical products. The NEX DE also supports

21 CFR Part 11 regulations using SureDI software. This option simplifies compliance

efforts without compromising performance.

Rigaku RPF-SQX fundamental parameters (FP)

RPF-SQX is an advanced FP that uses advanced profile fitting and theoretical fundamental equations to obtain concentration results without any reference samples. Matching Libraries are easily created by the user and are used in conjunction with the standard FP library in the modeling of a sample matrix and calculation of concentration results. This allows for a semi-quantitative measurement of elemental concentrations without needing a large suite of known assayed calibration standards. Standardless semi-quant is excellent for screening, research, and comparative analyses.

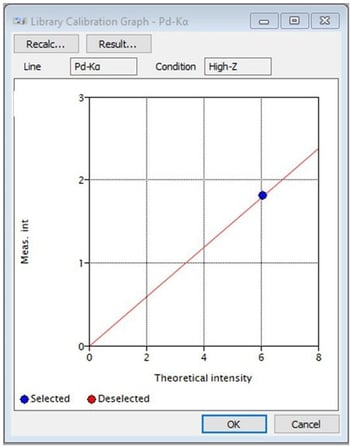

Rigaku matching library approach

The NEX DE software allows users to easily create their own Matching Libraries to fine-tune semi-quant results. A Matching Library uses one or more samples with known elemental concentrations assayed by a referee technique such as ICP. The theoretical intensities calculated by FP are adjusted to match the intensities of the standard sample and ICP concentration results, optimizing the accuracy of the FP results.

The NEX DE software allows users to easily create their own Matching Libraries to fine-tune semi-quant results. A Matching Library uses one or more samples with known elemental concentrations assayed by a referee technique such as ICP. The theoretical intensities calculated by FP are adjusted to match the intensities of the standard sample and ICP concentration results, optimizing the accuracy of the FP results.

To obtain the results demonstrated, a Matching Library was created using a sample assayed by ICP.

NEX DE results

Results for Pd using Matching Library and semi-quant screening results for other elements of interest.

| Sample ID: Unknown Sample | Units: ppm | ||

| Component | Assay value | NEX DE value | Stat. error |

| Pd | 45 | 48 | 0.8 |

| Si | -- | (13) | 2.8 |

| P | -- | ND | 1.8 |

| Cl | -- | 303 | 1.2 |

| Fe | -- | (2.0) | 0.5 |

| Br | -- | 3.5 | 0.1 |

Discussion

NEX DE uses the standard 10 mm collimator spot size. For smaller sample amounts, NEX DE VS variable spot system is equipped with small spot collimators for the measurement of sample spot 3 mm or 1 mm for Pd above the trace and ultra-low levels.

Accuracy is further improved by the use of more assayed matrix-matched assayed samples. For the highest degree of accuracy in measuring Pd, especially at the low and trace levels, empirical best-fit regression calibration can be made instead of using FP. By the empirical approach, 5 or more accurately and precisely assayed samples that span the Pd concentration range of interest are used to best-fit regression calibration, defining exactly the X-ray sensitivity in relation to concentration.

SureDI software package

Various software options are available to meet user needs, including SureDI, supporting compliance with 21 CFR Part 11. This option allows organizations in regulated industries, such as pharmaceuticals, to meet FDA requirements confidently.

Conclusion

The results demonstrated here show excellent sensitivity and precision for the measurement of Pd in cellulose powder. Other metals and elements of interest can also be measured in the same application method.

Rigaku Matching Library software allows the user to optimize accuracy using one or more assayed samples, and semi-quant allows for excellent screening with no reference samples. Advanced design features, including variable small spot capability in NEX DE VS combined with simple, intuitive software make NEX DE an excellent tool for process chemistry labs, R&D, and at-line monitoring alike.