Application Note EDXRF1924

Scope

The analysis of sulfur (S) and metals in bunker fuel and marine diesel are demonstrated.

Background

Regulations limiting the sulfur content of fuel used in the marine industry continues to evolve. As of January 1, 2015 the revised Annex VI to Marpol 73/78 reduced the maximum sulfur content allowed when entering ECAs (Emission Control Areas) to 0.1 wt%. After January 1, 2020 new IMO regulations require the sulfur content of any fuel used on board ships not to exceed 0.5 wt %. This is a substantial reduction from the 3.5 wt% limit established January 1, 2012. To meet the needs of the industry, Rigaku offers the NEX QC Marine Fuel Analyzer, a simple, versatile, and portable benchtop EDXRF analyzer for the analysis of sulfur in marine fuels. In addition to sulfur, the unit can be set up to monitor the nickel (Ni), vanadium (V), and iron (Fe) content of residual oils or to ensure fuels have not been adulterated with used engine oil or other undesirable oils. Screening for zinc (Zn) will help ensure fuels are free of used engine oil.

Marine Sulfur-Pak™: 0.05 – 3.50% Sulfur

Calibration

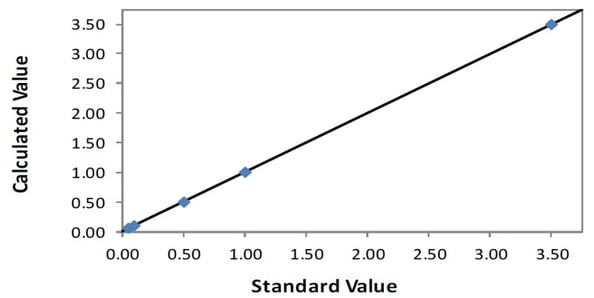

An empirical calibration was built using a set of commercially available mineral oil standards. A summary of the calibration is

shown here.

| Element: S Units: % |

||

| Sample I.D. | Standard value | Calculated value |

| STD 1 | 0.050 | 0.0495 |

| STD 2 | 0.100 | 0.0993 |

| STD 3 | 0.500 | 0.5027 |

| STD 4 | 1.000 | 0.9980 |

| STD 5 | 3.500 | 3.5000 |

Correlation plot S

Correlation plot S

The Marine Sulfur-Pak is ideal for measuring diesel 0.05 – 1.0% targeting 0.1% sulfur and bunker fuels 0.1 – 3.5% targeting 0.5% sulfur.

Repeatability

To demonstrate repeatability, samples were measured in static position for ten repeat analyses with typical results shown below.

| Element: S Units: % |

||||

| Sample I.D. | Standard value | Average value | Std. dev | % Relative |

| STD 1 | 0.100 | 0.0992 | 0.0010 | 1.0 |

| STD 3 | 0.50 | 0.4972 | 0.0021 | 0.4 |

International standard test methods for sulfur

The Rigaku NEX QC complies with the following international standard test methods for measuring sulfur in crude, bunker fuel, diesel, and other petroleum oils. Note that by weight 1 ppm = 1 mg/kg.

| ASTM D4294 | ISO 20847 | ISO 8754 | IP 496 | IP 336 | JIS K 2541-4 |

| 16 ppm – 5% | 30 – 500 mg/kg | 100 mg/kg – 5% | 100 mg/kg – 5% | 100 mg/kg – 5% | 0.01 – 5% |

Sulfur and metals in bunker fuel

Calibration

Empirical calibrations were built using a suite of 12 commercially available residual oil calibration standards. A summary of the empirical calibrations is shown here.

| Element | Concentration range |

| S | 0.24 – 5.50 % |

| Ni | 3 – 100 ppm |

| V | 25 – 500 ppm |

| Fe | 15 – 500 ppm |

Repeatability

To demonstrate repeatability, samples were measured in static position for ten repeat analyses with typical results shown below.

| Sample: Std. 2 | ||||

| Element | Standard value | Average value | Std. dev | % Relative dev |

| S | 0.50 % | 0.503 | 0.007 | 1.4 |

| Ni | 10 ppm | 11 | 0.6 | 6.0 |

| V | 500 ppm | 501 | 5 | 1.0 |

| Fe | 300 ppm | 300 | 3 | 1.0 |

Conclusion

The performance shown here demonstrates the ability of the NEX QC to yield excellent results for the measurement of sulfur and metals in bunker fuel and marine diesel. The system also has the capabilities to screen for elements such as Zn, Ni, and V in adulterated fuels.

The simple user interface and low-maintenance requirements of the NEX QC allow operators of all skill levels to use and maintain the equipment.