Application Note EDXRF1575

Scope

The measurement of silver (Ag) and copper (Cu) in copper ore is demonstrated.

Background

Silver naturally occurs in various ore and minerals, often as sulfides or chlorides or in combination with arsenic or antimony. A main source of silver is found in copper ore, as well as in copper-nickel, gold, lead, and lead-zinc ores. Silver and other precision metals are also reclaimed from tailing piles or other recycled ore materials that would previously be discarded. Therefore, the silver must often be measured at relatively low levels, as low silver levels can be considered profitable to extract. To meet the challenges of low-level silver analysis in ore and ore materials, Rigaku offers the NEX DE EDXRF analyzer with 60 kV excitation source and high-throughput SDD detector capable of yielding 500,000+ cps, giving the analyst and technician alike a fast, simple, yet powerful means for measuring elemental composition.

Calibration

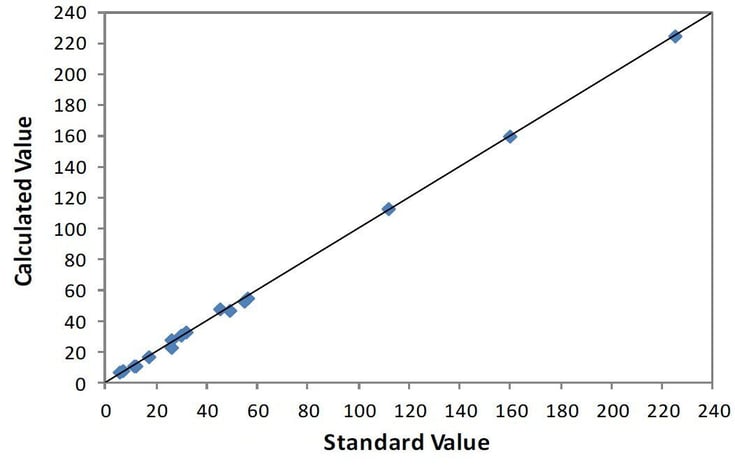

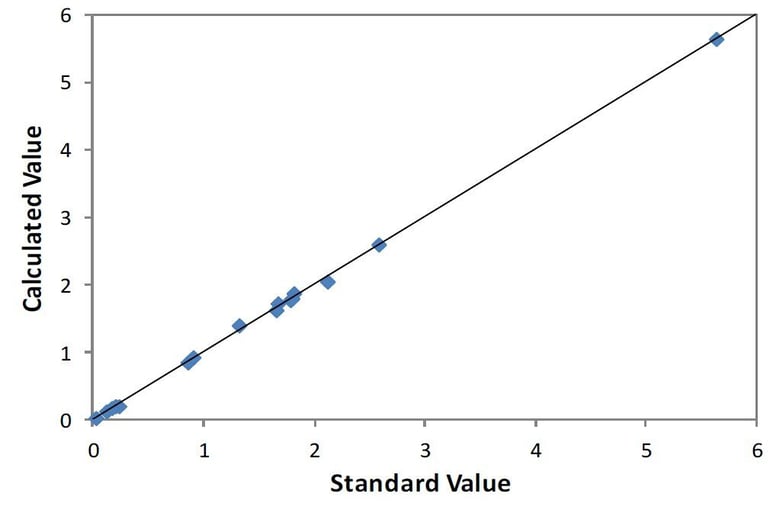

In order to give the highest degree of accuracy calibration is performed by empirical regression. To demonstrate calibration 16 assayed standards were provided by a mining company that characterizes the ore content of various mine sites. The calibrations for silver and copper are shown here. Matrix effects are compensated for using regression-based “alpha” corrections based on other major and minor elements present in the material. This provides the most accurate model of the particular ore composition being measured.

Silver calibration

| Element: Ag Units: ppm |

||

| Sample I.D. | Standard value | Calculated value |

| 2788.1 | 111.8 | 112.5 |

| 2788.2 | 26.2 | 27.9 |

| 2788.3 | 225.0 | 225.0 |

| 2792.4 | 56.0 | 54.9 |

| 2792.5 | 32.0 | 32.5 |

| 2792.6 | 45.0 | 47.7 |

| 2775.1 | 11.0 | 10.8 |

| 2775.3 | 5.3 | 6.6 |

| 6054 | 17.0 | 17.2 |

| 6055 | 160.0 | 160.1 |

| 6443 | 26.0 | 23.5 |

| 6466 | 12.0 | 10.7 |

| 5766 | 55.0 | 53.1 |

| 3638 | 49.0 | 46.8 |

| 2411 | 30.0 | 31.0 |

| 9745 | 6.7 | 8.5 |

Correlation plot Ag

Correlation plot Ag

Copper calibration

| Element: Cu Units: % |

||

| Sample I.D. | Standard value | Calculated value |

| 2788.1 | 2.13 | 2.06 |

| 2788.2 | 1.79 | 1.78 |

| 2788.3 | 5.64 | 5.64 |

| 2792.4 | 1.82 | 1.87 |

| 2792.5 | 1.80 | 1.80 |

| 2792.6 | 0.86 | 0.85 |

| 2775.1 | 0.13 | 0.13 |

| 2775.3 | 0.24 | 0.21 |

| 6054 | 0.03 | 0.03 |

| 6055 | 2.59 | 2.59 |

| 6443 | 1.32 | 1.39 |

| 6466 | 0.20 | 0.20 |

| 5766 | 1.68 | 1.72 |

| 3638 | 0.91 | 0.91 |

| 2411 | 1.67 | 1.63 |

| 9745 | 0.18 | 0.17 |

Calibration plot Cu

Calibration plot Cu

Recovery and repeatability

To demonstrate typical measurement recovery and repeatability (precision), two calibration standards were chosen to show the low and high concentrations of silver and copper. 10 repeat measurements of each sample were taken with the average results and standard deviations are shown here.

|

Sample: 2.775.1 |

Units: ppm |

|||

|

Element |

Assay value |

Average value |

Std. dev |

Relative dev |

|

Ag |

11 |

11.1 |

0.3 |

3.0 |

|

Ag |

225 |

227 |

1.6 |

0.7 |

|

Sample: 2.788.3 |

Units: % |

|||

|

Element |

Assay value |

Average value |

Std. dev |

Relative Dev |

|

Cu |

0.13 |

0.124 |

0.0004 |

0.3 |

|

Cu |

5.64 |

5.67 |

0.0054 |

0.1 |

Analysis of production samples

Several production samples with expected values were provided by the mine sites for measurement. The results are summarized here.

| Element: Ag | Units: ppm | |

| Sample | Expected value | NEX DE result |

| A | 11 | 12 |

| B | 18 | 16 |

| C | 58 | 57 |

| D | 45 | 44 |

| E | 31 | 33 |

| F | 8.3 | 7.5 |

| Element: Cu | Units: % | |

| Sample | Expected value | NEX DE result |

| A | 0.19 | 0.18 |

| B | 0.15 | 0.14 |

| C | 1.62 | 1.66 |

| D | 0.87 | 0.88 |

| E | 1.64 | 1.58 |

| F | 0.12 | 0.18 |

Conclusion

The Rigaku NEX DE combines filtered direct excitation with a high performance SDD detector capable of 500,000+ cps throughput. This delivers excellent sensitivity for the measurement of higher atomic number elements like silver. The NEX DE analyzer is capable of elemental analysis from Na – U, making the XRF technique ideal for other elements, as well. This power and simplicity makes the analyzer an ideal tool for the precise measurement of low levels of precious metals in ore, as well as the major and minor ore constituents.