Application Note EDXRF1559

Scope

The analysis of low silicone coating on plastic is demonstrated.

Background

Barrier coatings (packaging & specialty plastics)

Thin silicone coating is excellent at reducing the ingress of water and oxygen into packaged products. Applications include plastics used for food packaging as well as pharmaceutical and medical packaging. Specialty plastics are also often coated with a thin silicone coating used as a barrier coating or release coating.

Thermoformed plastics

Thermoformed plastics are used globally for food as well as consumer goods

packaging. Polymer films, when in contact with each other as a roll or stack, tend

to block or stick together. Coating with a very low coat weight of silicone prevents this giving them the de-nesting characteristics the industry desires. In the logistics of producing, storing, and using thermoformed plastic, undercoating causes the plastics to stick together. Over-coating has the potential to negatively impact the clarity of the packaging (product inside the package is blurred when viewed). A typical coat weight is less than 0.2 g/m² (200 mg/m²).

Rigaku NEX QC+ analyzer meets the challenges of the coated plastics industry with several modern features:

- No need to use He purge for typical coat weights

- No special sample preparation or sample cup requirements

- Sample tray option for high-throughput applications such as the labeling market

Quantification units

Coat weight is expressed as mass/area, the amount of silicone per unit area of plastic. While typical coat weights in the label industry in the range of 0.2 – 2.0 g/m² (also called gsm), the lower silicone levels used as barrier coatings and in thermoforming are mg/m² and typically fall in the range 50 – 500 mg/m² (0.05 – 0.5 g/m²).

Quantification and calibration

To demonstrate the principle of quantifying the coat weight, a simple 2-point calibration was made using two samples of known silicone coat weights of 50 and 500 mg/m².

Repeatability

To demonstrate repeatability (precision), the low and high coat weight samples were chosen from the set of calibration standards. Each sample was measured in a static position for ten repeat analyses with typical results shown below.

| Element: Si Units: mg/m² |

||||

| Sample I.D. | Standard value | Average value | Std. dev | % Relative |

| 50 | 50.0 | 50.1 | 0.5 | 1.0 |

| 500 | 500.0 | 500.8 | 2.2 | 0.4 |

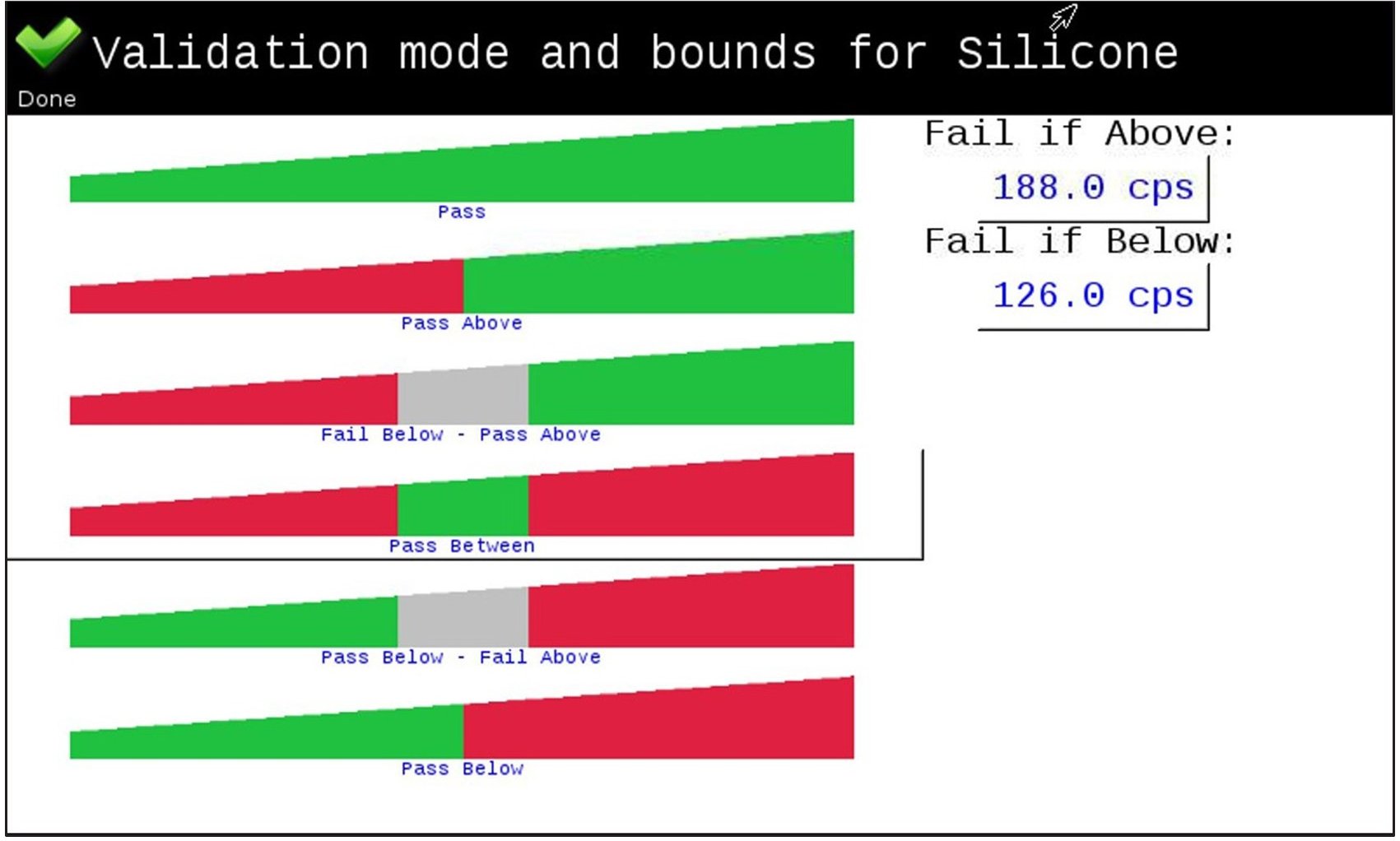

Simple trend analysis

Often in the industry, it is not necessary to quantify the silicone coat weight, but the need is to simply know whether the silicone has been applied. This type of trend analysis can be easily done on NEX QC+ by measuring the Si X-ray intensity and using the NEX QC+ Validation feature. For trend control, only one sample is required with a silicone coating considered to be the good target level. The mg/m² coat weight does not need to be known. This sample is measured as a 1-point calibration, and the Validation feature is enabled.

In this example, a good sample is used and measured to have 157 cps Si. The Pass Between Validation scheme is chosen with typical bounds entered as ±20%.

Trend analysis results

Trend analysis results

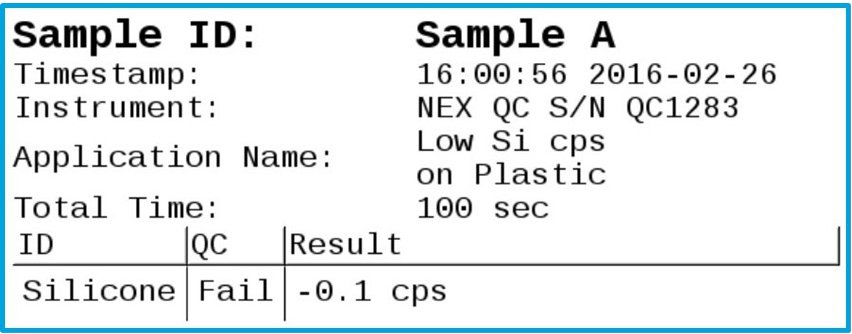

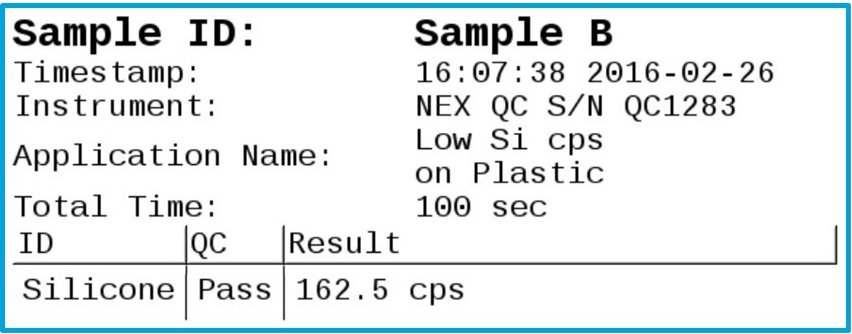

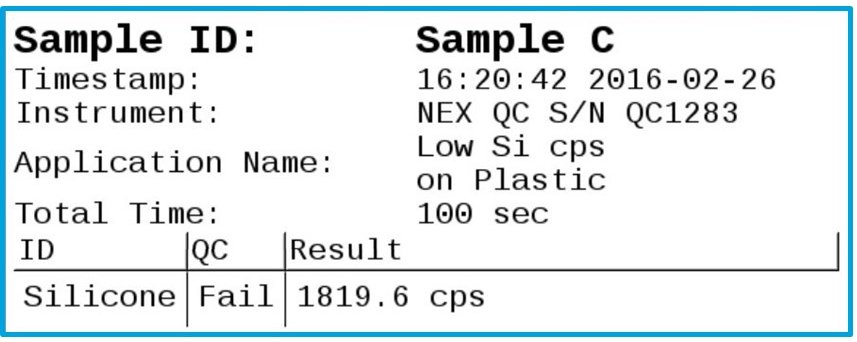

The following examples demonstrate the use of the Validation feature for trend control without the need to quantify silicone coat weight.

|

Sample A failed due to undercoating. Trend validation helps prevent product rejection. |

|

Sample B passes, indicating the desired amount of silicone coating has been applied. |

|

Sample C failed due to over-coating, indicating cost overruns in the use of excess silicone material. |

Conclusion

The typical results detailed here show the exceptional performance of the Rigaku NEX QC+ for fast and simple measurement of silicone coatings on plastic. It is a modern and affordable tool for reducing running costs, product rejection, and product waste.