Application Note EDXRF1177

Scope

The analysis of iron oxide in silica sand is demonstrated.

Background

One of the major uses of silica sand is to make glass, and in particular, glass bottles. The iron content is one of the major factors that affect the color of the glass. Low iron sands are used to produce clear glass for bottles, while sand with higher iron content is used to make amber glass bottles. Thus, both at the quarry site and in the manufacturing process, monitoring the iron content is very important to ensure the quality of the glass products. The Rigaku NEX QC is an ideal tool for reliably measuring the iron content in sand, and can be used at the quarry along the production line to help ensure the highest quality while minimizing wastes and cost overruns.

Calibration

Seven assayed standards were used for calibration.

| Element: Fe₂O₃ Units: % |

||

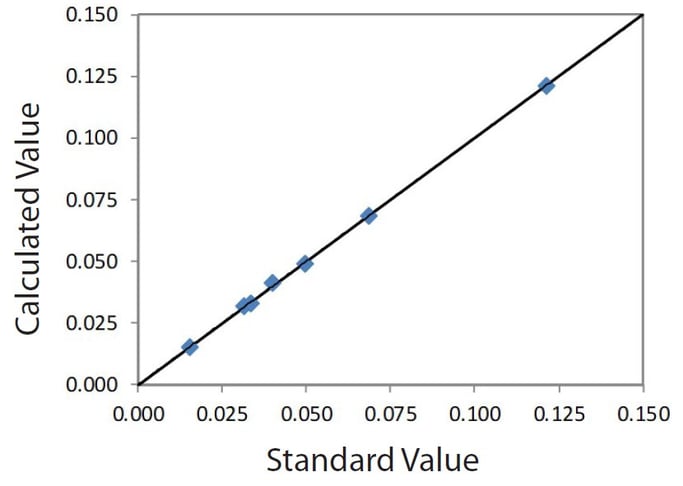

| Sample I.D. | Standard value | Calculated value |

| A | 0.0151 | 0.0152 |

| B | 0.0315 | 0.0319 |

| C | 0.0332 | 0.0328 |

| D | 0.0400 | 0.0410 |

| E | 0.0495 | 0.0491 |

| F | 0.0683 | 0.0682 |

| G | 0.1210 | 0.1210 |

Correlation plot Fe₂O₃

Repeatability

To demonstrate repeatability (precision), the low and high calibration standards were each measured without moving the sample between measurements.

|

Element: Fe₂O₃ |

|||

|

I.D. |

Standard value |

NEX QC average result |

Std. dev (σ) |

|

A |

0.0151 |

0.0153 |

0.0008 |

|

G |

0.1210 |

0.1201 |

0.0008 |

Conclusion

The results show NEX QC provides excellent performance for the measurement of iron oxide in silica sand. The NEX QC offers a simple and fast means of analysis during the QA/QC process in the production of glass bottles, as well as for screening at the quarry.