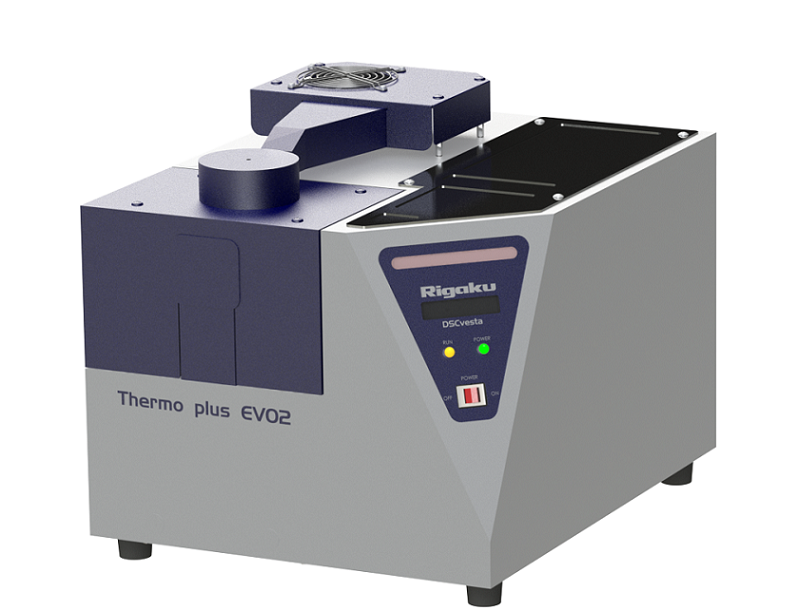

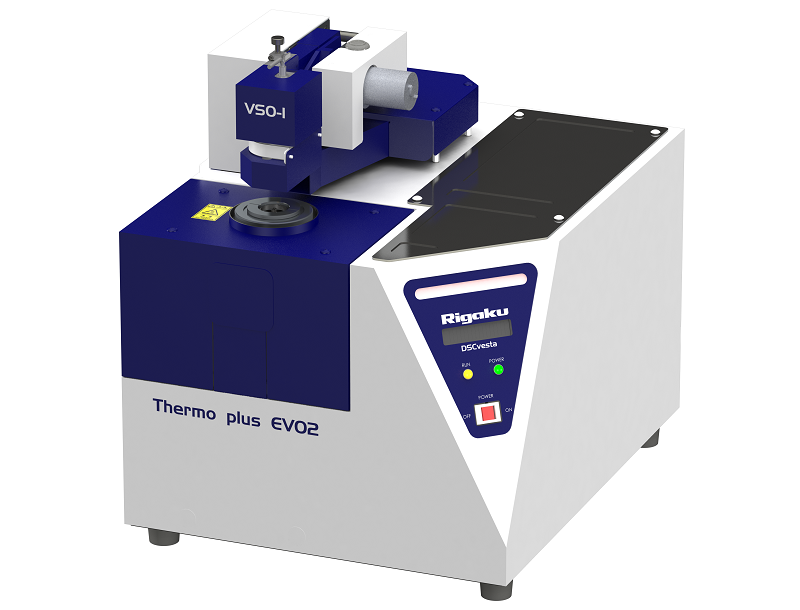

DSCvesta

Differential Scanning Calorimeter

Characterize heat gain/loss associated with phase transitions

Differential scanning calorimetry (DSC) quantifies the energy changes in reactions such as melting, transition, crystallization and glass transition temperature and is mainly used for research and development; and quality control in the fields of polymer, pharmaceutical.

Rigaku’s DSC are heat-flux types. Several models are available depending on the maximum temperature and sensitivity difference.

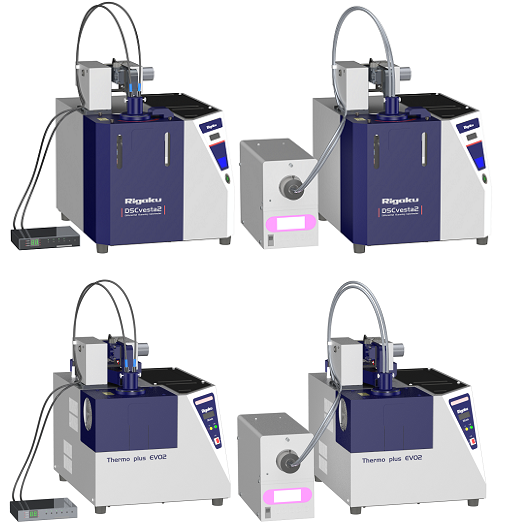

The high-sensitivity type DSCvesta has several available options, such as a refrigerated cooling system, an automatic sample changer, sample observation, depending on the objective of the measurement.

DSCvesta Features

(When using with cooling unit lowest temperature: -70℃)

DSCvesta Videos

DSCvesta Specifications

| Technique | Differential scanning calorimetry | |

|---|---|---|

| Benefit | Characterize and quantifies the energy of a reaction associated with phase changes | |

| Technology | DSC is a thermal analysis technique in which the difference in the amount of heat required to increase the temperature of a sample and reference is measured as a function of temperature | |

| Attributes | Using this technique it is possible to observe fusion and crystallization events as well as glass transition temperatures and can be also used to study oxidation, as well as other chemical reactions | |

| Options | ASC, sample observation unit, cooling unit | |

| Computer | External PC | |

| Dimensions | 380 (W) x 367 (H) x 492 (D) (mm) | |

| Mass | 28 kg (38 kg w/ ASC) | |

| Power requirements | 1Ø, AC100-120V/200-240V 50/60Hz 5A | |

DSCvesta Options

The following accessories are available for this product:

DSCvesta Cooling Unit

We have four different types of cooling units available to meet the purpose of your measurement and desired temperature range.

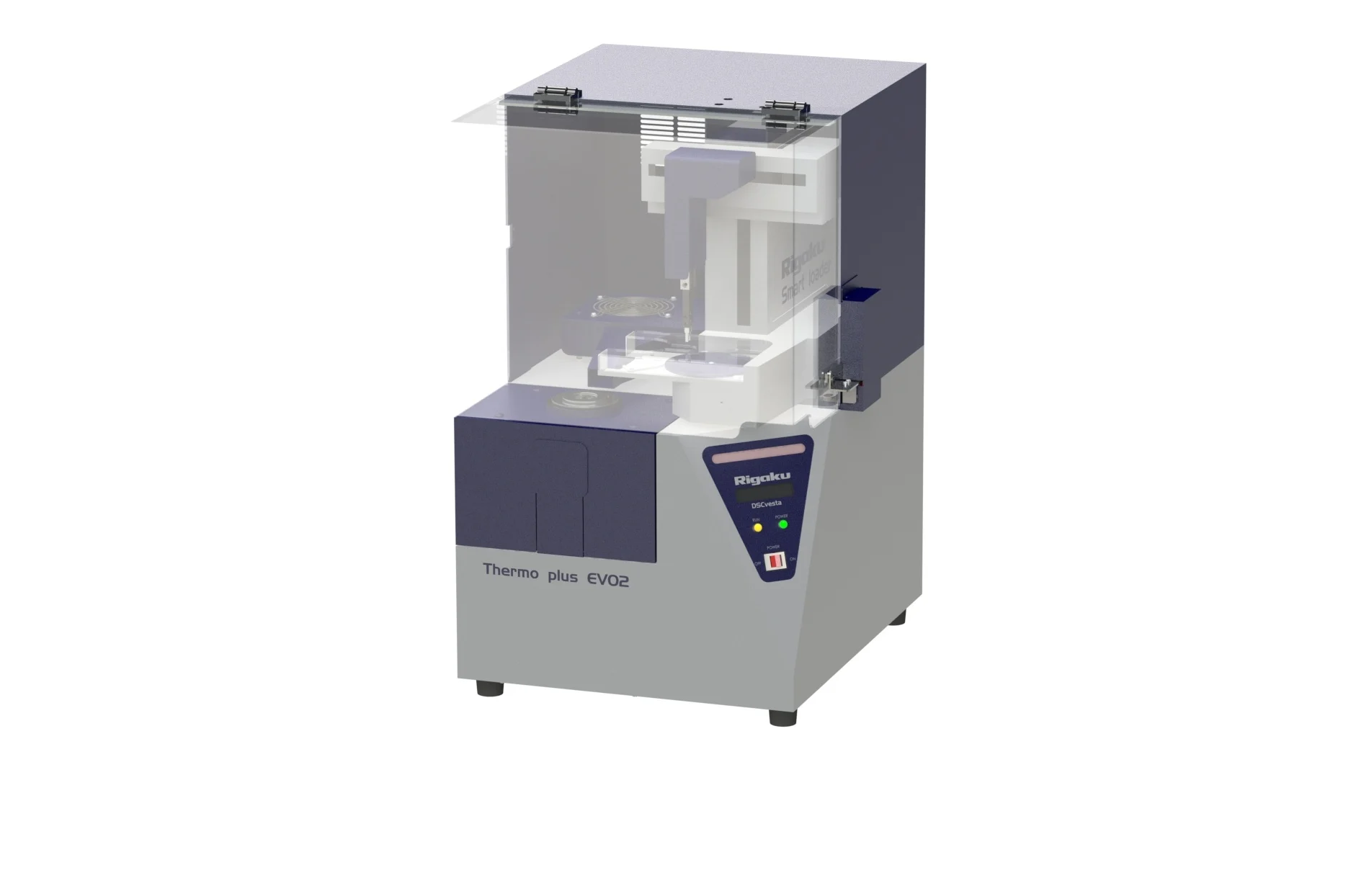

Safety cover for DSCvesta

Encloses the automatic sample changer and furnace to ensure safety during measurements.

Sample Pan

Depending on the sample to be measured (especially if the sample is metal), it may melt the sample pan and damage the sample holder or other parts of the instrument.

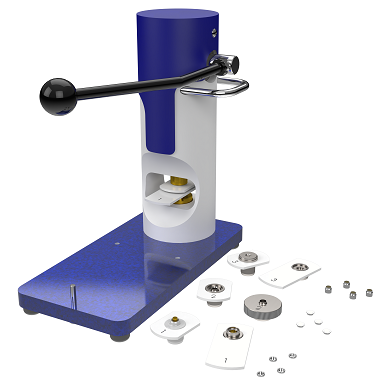

Sample sealer / Sample crimper

A sample pan shaping tool with three functions: sample crimper, sample sealer, and high-pressure sample sealer.

Flow Meter

The flow meter controls the flow rate of the atmospheric gas (inert gas, air, etc.) supplied to the sample chamber.

Gas Selector

Links to the measurement program and switches the gases flowing into the sample chamber.

2ch-FLOW COMPO Jr.

Enables gas flow, flow rate setting and switching of gases with precision specified in the measurement program. Gas types and full scale can be selected.

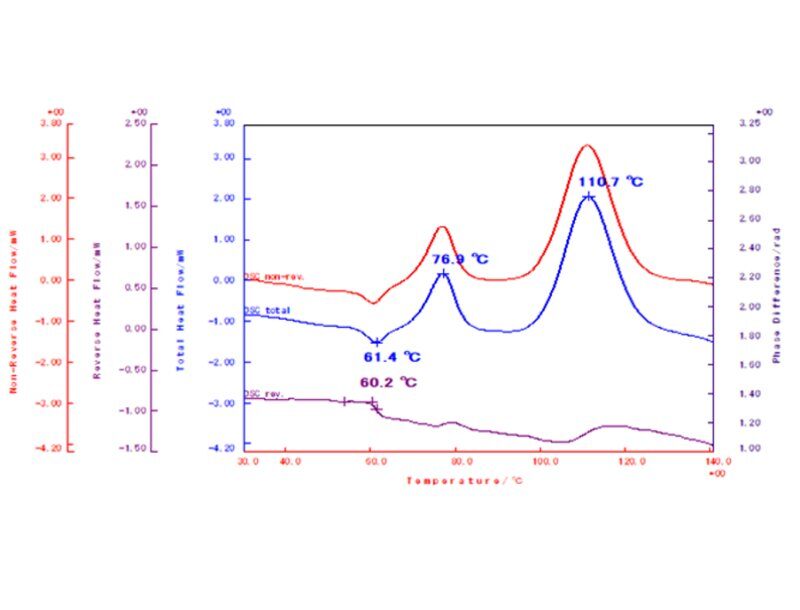

Dynamic DSC

This technique allows for the separation of overlapping reactions and facilitates the straightforward determination of specific heat capacity.

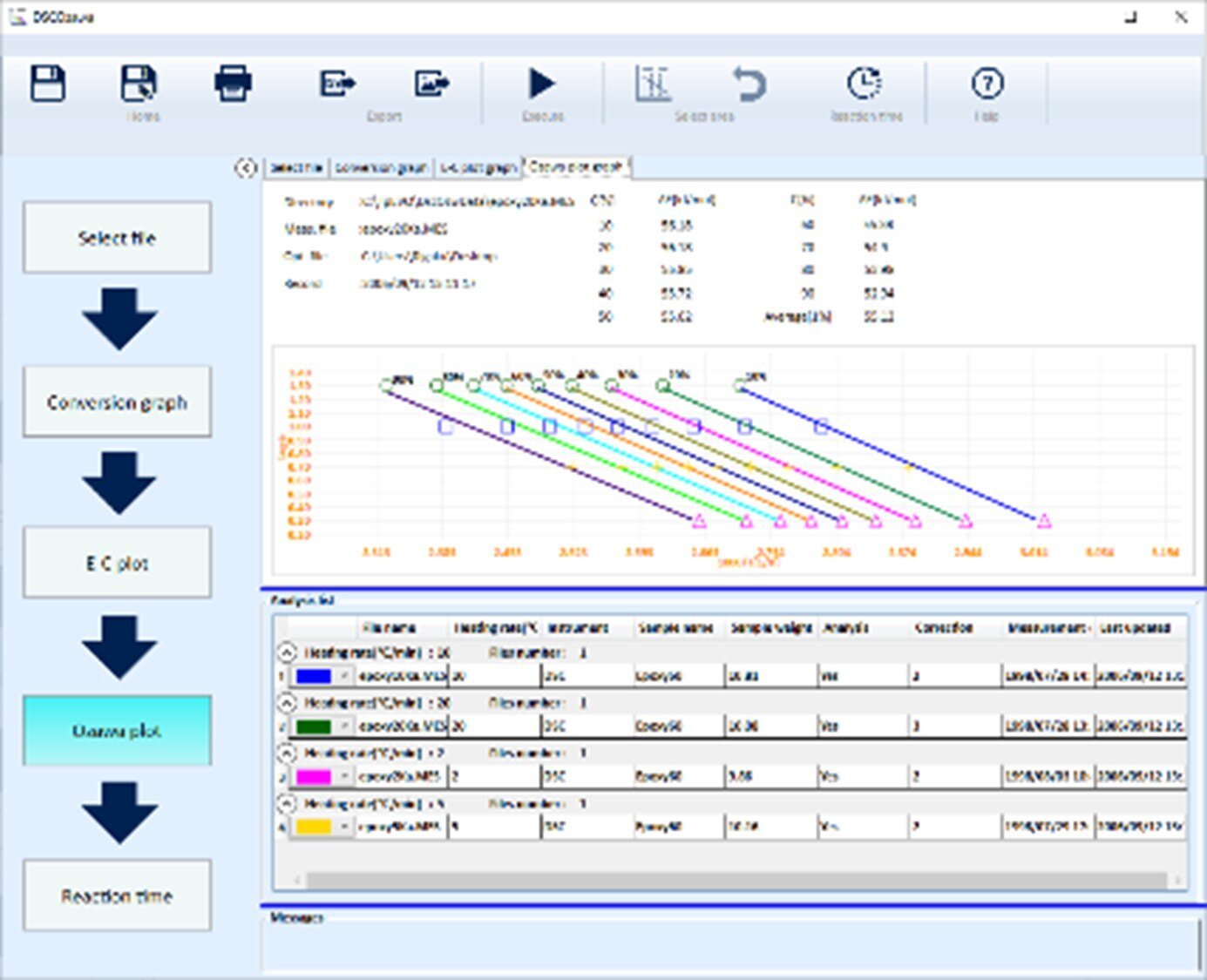

DSC Ozawa method/TG Ozawa method

In this method, the activation energy can be estimated from more than three measurements with different heating rates, estimating the time to reach a defined degree of conversion.

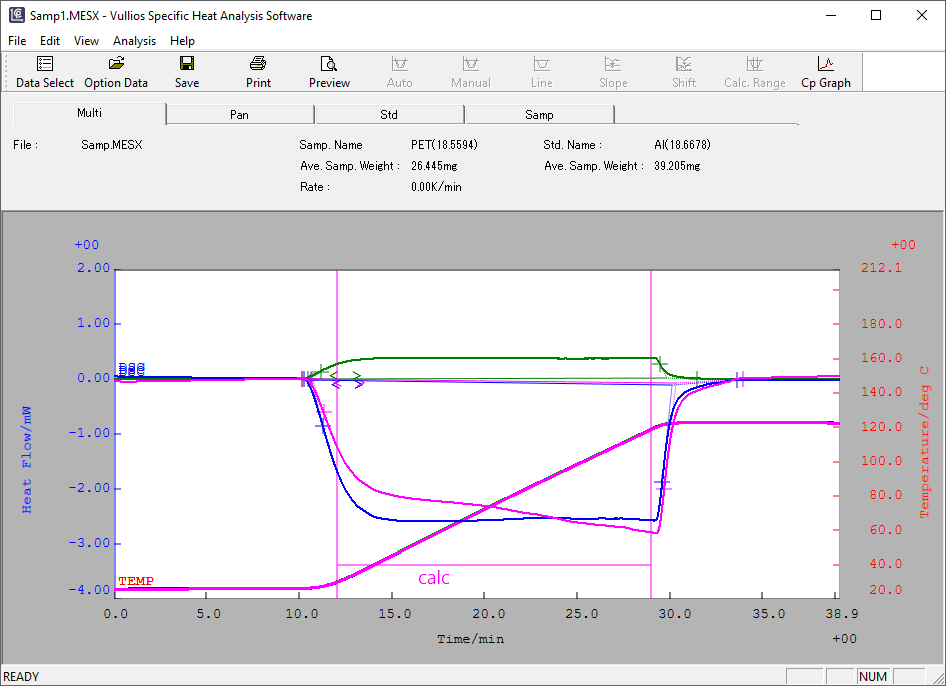

DSC Specific heat Analysis

The specific heat capacity at each temperature is calculated based on the amount of baseline shift from three different measurement results: sample pan, sample with a known specific heat and unknown sample.

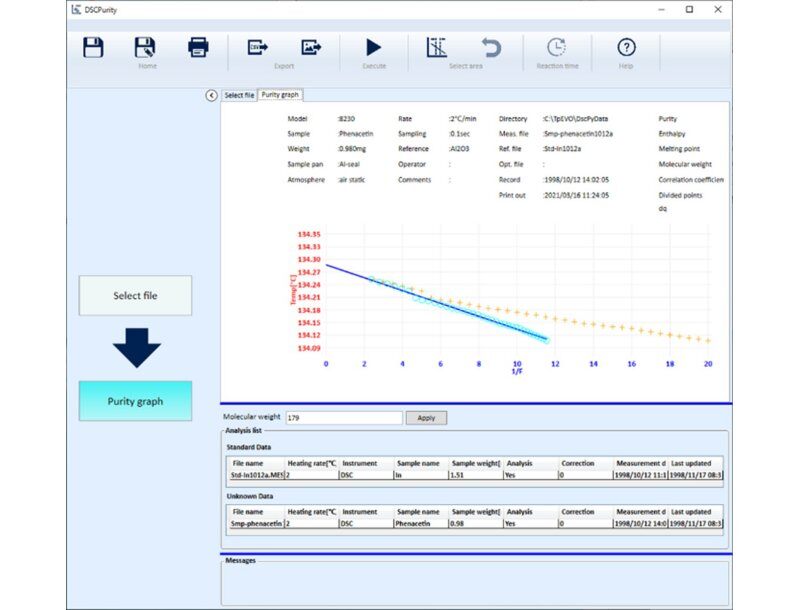

DSC Purity Analysis

DSC purity analysis is performed using analyzed data files of standard samples and unknown samples that have undergone energy analysis.

DSCvesta Resources

Webinars

| Using Thermal Analysis to Characterize Amorphous Pharmaceutical Materials | Watch the Recording |

| Rigaku Technical Seminal in Thermal Analysis Focusing On Pharmaceutical Applications | Watch the Recording |

Rigaku Journal articles

| Read the Article |

DSCvesta

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.