TMA8311

Thermomechanical Analyzer

Measurement of a mechanical property change with respect to temperature

TMA is technique in which a non-oscillatory load is applied such as in compression, tension or bending, measuring the changes in the sample shape when the sample is heated or cooled. The TMA method includes measurement modes such as compression loading method, tensile loading method, penetration method and 3-point bending based on the sample shape and the objective of the measurement. TMA is widely used to measure the thermal expansion ratio and softening temperature of a sample.

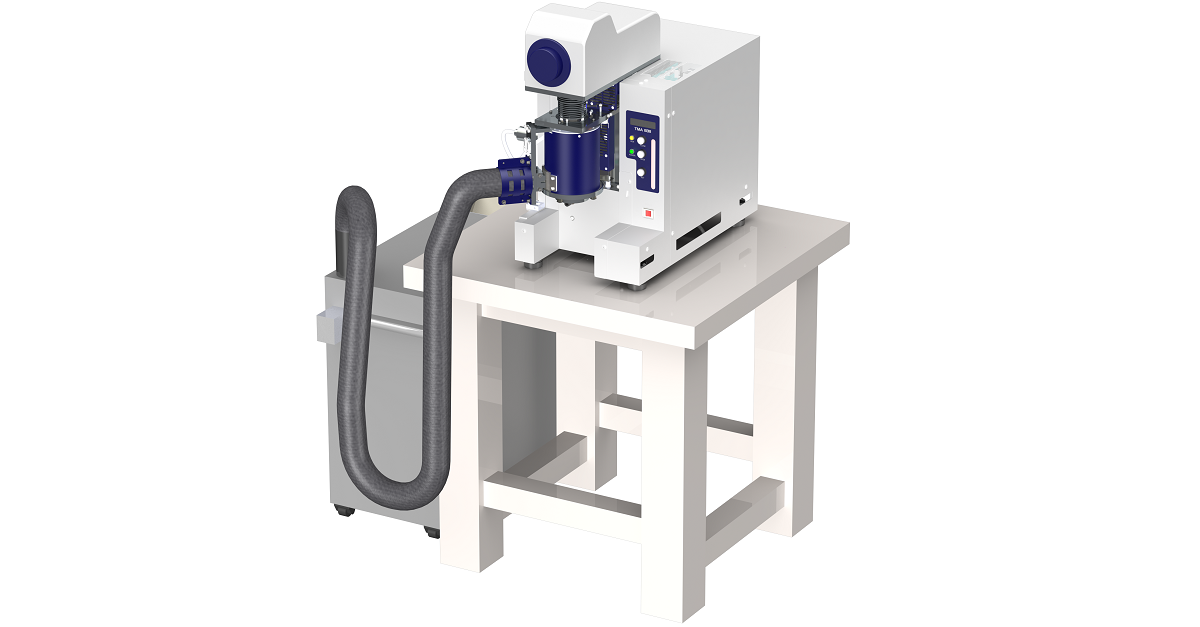

TMA8311 Overview

Rigaku’s TMA adopts the differential expansion principle that cancels the thermal expansion or shrinkage generated from the detection mechanism itself. In addition to constant load, the load control can be set to two types: constant rate loading mode and sine-wave cyclic loading mode.

Sample controlled TMA (SCTMA), where the shrinkage rate controls the temperature, can be installed as an option that is effective for the simulation of sintering in ceramics, production of sintered materials with suppressed grain growth.

TMA8311 Features

- Compression loading method

- Tensile loading method

- Penetration method

- High-sensitivity differential penetration method

- Standard model: Ambient to 1100°C

- High-temperature model: Ambient to 1500°C

- Low-temperature model: -150 to 600°C

TMA8311 Specifications

| Technique | Thermomechanical analyzer | |

|---|---|---|

| Benefit | Measurement of a mechanical property change with respect to temperature | |

| Technology | Differential expansion principle where the thermal expansion or shrinkage generated from the detection mechanism itself can be canceled | |

| Core attributes | Multi-measurement system that excels in expandability | |

| Computer | External PC | |

| Core dimensions | 380 (W) x 580 (H) x 580 (D) (mm) | |

| Mass | 30 kg (core unit) | |

| Power requirements | 1Ø, AC100-120 V/200-240 V 50/60 Hz 15 A | |

TMA8311 Options

The following accessories are available for this product:

Gas Selector

Links to the measurement program and switches the gases flowing into the sample chamber.

Flow Meter

The flow meter controls the flow rate of the atmospheric gas (inert gas, air, etc.) supplied to the sample chamber.

2ch-FLOW COMPO Jr.

Enables gas flow, flow rate setting and switching of gases with precision specified in the measurement program. Gas types and full scale can be selected.

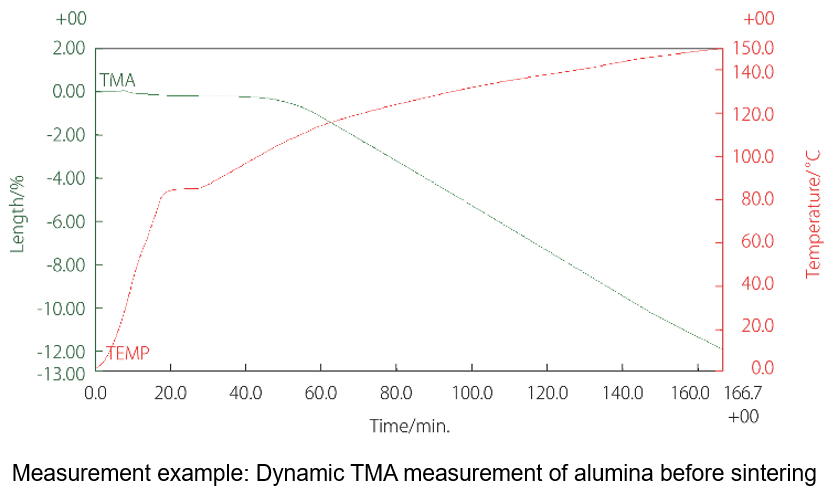

Dynamic TMA

With this unit, temperature control is performed with the sample’s shrinkage rate as a parameter, not with the constant temperature heating rate.

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.