Application Note TA5014

Introduction

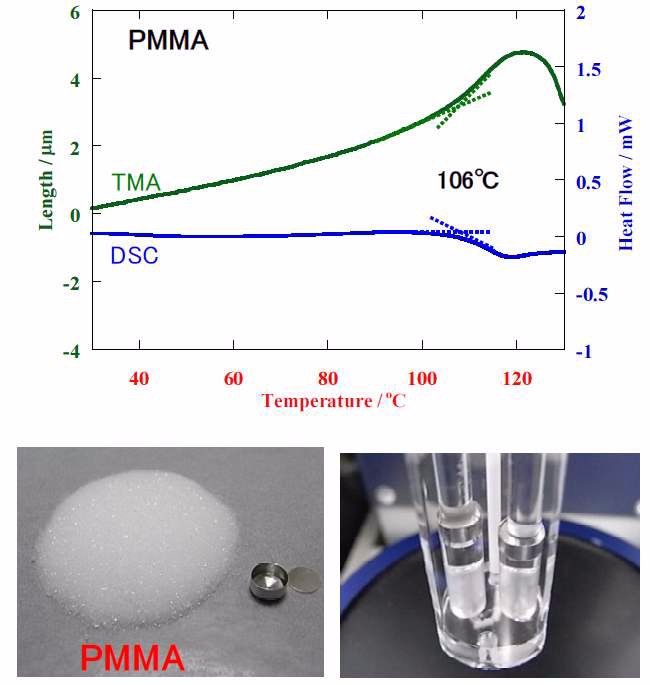

We measured the expansion of powdered polymethylmethacrylate (PMMA) using TMA. Also, to verify it, we performed DSC measurement from point of view of energy change.

Instrument

TMA adopts the Rigaku’s establishment reputation on differential expansion principle where the thermal expansion or shrinkage generated from the detection mechanism itself can be cancelled. It offers high accuracy and excellent reproducibility in expansion and shrinkage measurements, even with low expansion materials or thin materials.

DSC8231

Featuring a new electric furnace and new electric furnace circuit technology, this system offers low noise and improved baseline stability.

Measurement and analysis

The PMMA powder is placed at sample pan of Al and, the empty pan with lid of Al is placed at reference side.

TMA measurement results in Figure 1 show an expansion curve with slope change at 106℃ due to glass transition of PMMA. After the glass transition, the sample presents a shrinkage curve due to softening. While DSC measurement shows the baseline shifts as a result of glass transition at around same temperature. In usual, TMA measurement can be observed as change in form, and DSC measurement can be observed as change in energy.

Thus, the differential expansion mode can be measured the powder sample, subtracted empty pan with lid from measurement sample including sample pan.

Figure 1: TMA measurement result for PMMA powder