Application Note B-TA1004

Introduction

TMA can measure the materials’ expansion and softening by changing the detection rod. Moreover, there are two types of TMA: non-differential (or single rod) expansion method and differential expansion method. When measuring a coated sample by non-differential expansion method, the obtained results will be the total amount changes consist of the main material and the coating material, therefore it is necessary to measure only the main material separately.

Measurements and results

Measurements are performed using the differential penetration method with the main material steel set on the reference side and the steel coated with the coating material set on the sample side.

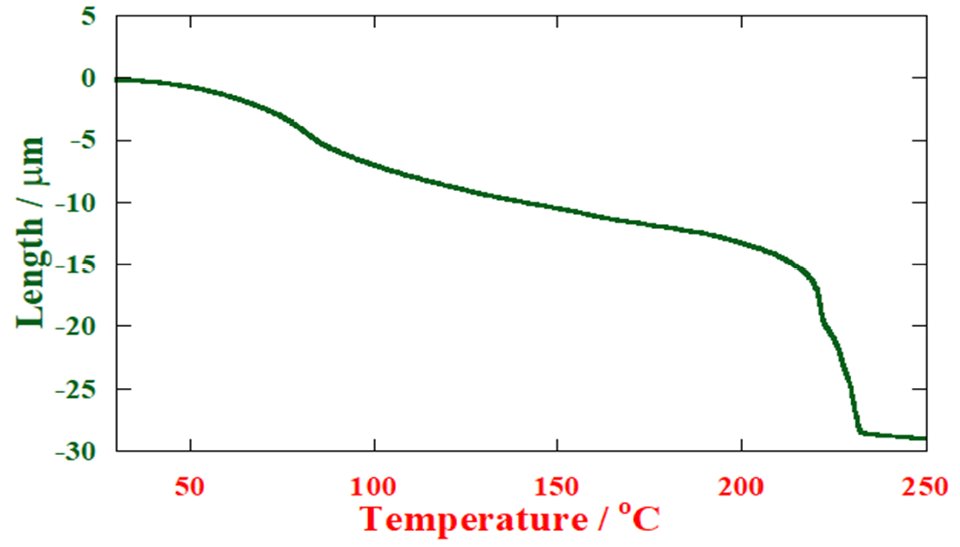

Figure 1 shows the results of differential penetration method. Results indicate shrinkage in the low and high temperature regions. Since the material is mainly made of steel, the thermal behavior should be expansion but the results shows shrinkage. The amount of change in the measurement consists of the expansion of the main material (steel) and the change in the coating material. Since the measurement is performed using steel as the reference material, the expansion of the reference material is canceled from the measurement of the sample. Therefore, the shrinkage of the measurement results is considered to be due to softening of the coating material coated on the steel.

In this manner, the expansion of the reference material steel can be canceled from the coated steel can, allowing the evaluation of the coated material using the differential penetration method.

Figure 1: Differential penetration measurement results of coating material applied to steel can