Application Note B-TA1049

Introduction

The influence of thermal degradation caused by high temperature exposure on the expansion ratio of fluoroelastomer O-rings was investigated.

Measurement and analysis example

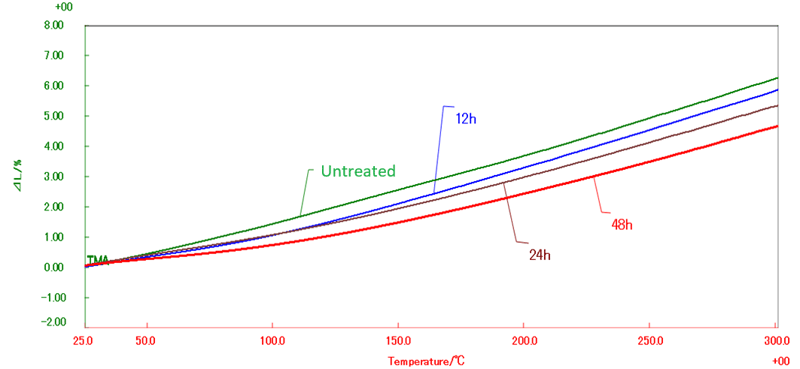

The samples were prepared under three conditions: 12, 24, and 48 hours of holding time at 300°C. The thermal expansion ratios were measured using the TMA compression loading method and compared with that of the untreated sample.

Figure 1: Comparison of TMA results for samples with different sample preparation conditions

Table 1: Expansion ratio (%) of samples with different sample preparation conditions

| Holding Temp. °C | Untreated | 12h | 24h | 48h |

| 50 | 0.41 | 0.33 | 0.34 | 0.22 |

| 100 | 1.40 | 1.05 | 1.01 | 0.69 |

| 150 | 2.53 | 2.10 | 1.88 | 1.43 |

| 200 | 3.66 | 3.29 | 2.92 | 2.39 |

| 250 | 4.92 | 4.54 | 4.08 | 3.45 |

| 300 | 6.22 | 5.85 | 5.27 | 4.61 |

When comparing the TMA results of untreated samples to those of samples held at 300°C for a fixed duration, the temperature-treated samples tend to exhibit a tendency toward lower expansion ratios. The samples held for 12 h and 24 h exhibit similar thermal expansion behavior up to around 130 °C, after which the difference between them becomes more pronounced. The sample held for 48 h shows a lower thermal expansion ratio beginning at approximately 50 °C.

In general, it is known that rubber undergoes hardening in the early stages of thermal degradation, and the decrease in thermal expansion ratio is presumed to be attributable to this hardening. In addition, the sealing performance of O‑rings is considered to be influenced by hardness, suggesting that the measurement of thermal expansion ratio can serve as an effective indicator for evaluating the degradation.

Recommended equipment and software

► Thermo plus EVO2 TMA8311 (Differential compression loading attachment)

► Vullios measurement and analysis software