Sample Observation STAvesta

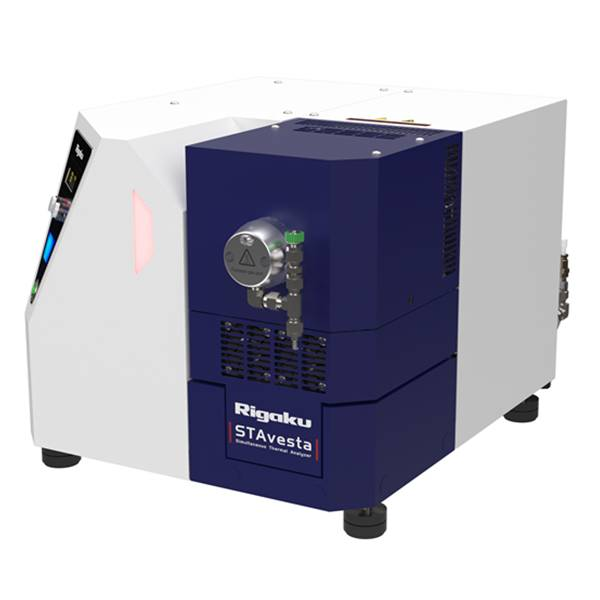

This is a thermogravimetry–differential scanning calorimetry (TG-DSC) system that enables visual observation of sample changes during thermal analysis.

It consists of the main STA unit and a microscope-integrated sample observation furnace equipped with an observation mechanism. This configuration allows for real-time monitoring and recording of sample changes over a temperature range from room temperature up to 1,000 °C.

The system enables monitoring of phenomena such as shrinkage behavior during sintering of ceramics, shape changes associated with the glass transition, softening, and flow of glass, as well as melting and foaming during the decomposition of polymers.

By analyzing the thermal data together with the captured images, users can gain deeper insight into material behavior and discover new findings.

Sample Observation STAvesta Overview

For details on the basic performance of STAvesta, please refer to the main STAvesta page.

Microscope-integrated furnace

The microscope-integrated furnace can be replaced just as easily as any of the other furnaces, ensuring simple and smooth switching.

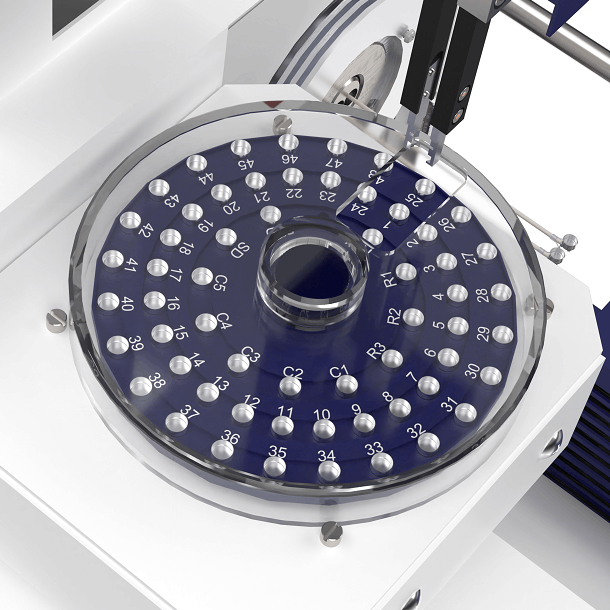

Compatible with Automatic Sample Changer (ASC)

This furnace is compatible with the optional automatic sample changer, enabling fully automated, unattended measurement and imaging.

Supports high-temperature range up to 1,000°C

Sample changes can be visually observed in real time during both heating from room temperature up to 1,000°C and cooling back down, offering valuable insight into thermal behavior at elevated temperatures.

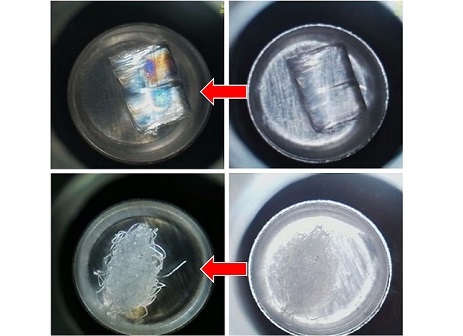

Devitrification prevention unit for clear observation

Gases released from sample decomposition may cause devitrification or staining of the quartz protection tube, making optical observation difficult. With the devitrification prevention unit installed, only a replaceable protection plate inside the protection tube is exposed to the gas. This prevents damage to the quartz tube itself, improving maintainability and helping to reduce running costs.

What is devitrification?

Devitrification is a phenomenon where transparent quartz loses its clarity due to a transition from an amorphous to a crystalline structure, typically caused by contact with alkali metal vapors or salts.

(Illustration)

| With devitrification prevention unit |

Without devitrification prevention unit |

|

| Before measurement | ||

|

|

|

| Heating (decomposition gas releasing) | ||

|

|

When gases that react with amorphous quartz are present, the interior of the protection tube can fill with gas. |

| After measurement | ||

|

|

Right (without unit): Left (with unit): |

Sample Observation STAvesta Features

Sample Observation STAvesta Videos

Sample Observation STAvesta Specifications

| Model name | Thermo plus EVO3 STAvesta/C Sample observation Simultaneous Thermal Analyzer |

|

|---|---|---|

| Technology | Thermogravimetry-Differential Scanning Calorimeter (TG-DSC) | |

| Measurement temperature range | Room temperature to 1,100°C*¹ | |

| Heating rage(max) | 100°C/min | |

| Sample amount (max) | 1 g (90 μL) | |

| TG range | ± 500 mg | |

| DSC range | ± 600 mW (100°C) ± 1,400 mW (1,000°C) |

|

| DTA range | ± 1,000 μV | |

| TG baseline drift volume *² | <10 μg (up to1,000°C) | |

| Measurement atmosphere | Air, inert gas, under reduced pressure*³ | |

| Options | Automatic sample changer (Sample: 52, reference: 3, calibration sample: 5) Furnace unit (Standard, high temperature, indirect heated, HUM, refrigerated cooling) ASC safety cover Devitrification prevention unit Reflection prevention filter |

|

| Dimensions | 412(W) x 456(H) x 561(D)(mm) 412(W) x 705(H) x 561(D)(mm) (with ASC) |

|

| Mass | 47 kg 57 kg (with ASC)、63 kg (with ASC and safety cover) |

|

| Power requirements | 1Ø, AC100-120 V/200-240 V, 50/60 Hz, 15 A | |

| *1 For sample observation measurement: up to1,000°C *2 Under Rigaku measurement condition *3 Not compatible with ASC measurement |

||

Sample Observation STAvesta Options

The following accessories are available for this product:

ASC for STAvesta

Optional ASC (Auto Sample Changer) for greater throughput Upgradeable with ASC for automated measurements

STAvesta ASC Safety cover

The ASC safety cover is designed to reduce mechanical hazards associated with the automatic sample changer (ASC).

Reflection prevention filter

Suppresses the reflection of the camera lighting during sample observation measurements of glossy or transparent samples

Sample Pan

Depending on the sample to be measured (especially if the sample is metal), it may melt the sample pan and damage the sample holder or other parts of the instrument.

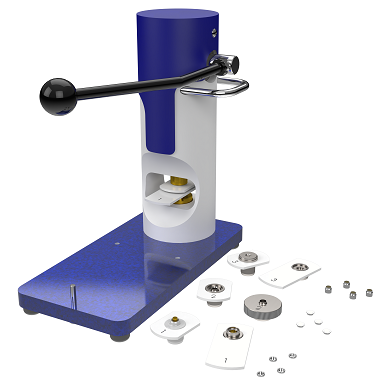

Sample sealer / Sample crimper

A sample pan shaping tool with three functions: sample crimper, sample sealer, and high-pressure sample sealer.

Flow Meter

The flow meter controls the flow rate of the atmospheric gas (inert gas, air, etc.) supplied to the sample chamber.

Gas Selector

Links to the measurement program and switches the gases flowing into the sample chamber.

2ch-FLOW COMPO Jr.

Enables gas flow, flow rate setting and switching of gases with precision specified in the measurement program. Gas types and full scale can be selected.

Sample Observation STAvesta

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.