STAvesta/HUM

Humidity controlled atmosphere STA (TG-DSC)

Easy TG-DSC measurement in a high concentration water vapor atmosphere

STAvesta/HUM combines a thermogravimetric-differential scanning calorimeter with a water vapor generator to perform TG-DSC measurements in a water vapor atmosphere. It features a polymer-type relative humidity sensor and a high-precision temperature sensor, providing fast response to changes in water vapor concentration and excellent long-term stability.

STAvesta/HUM Overview

For details on the basic performance of STAvesta, please refer to the main STAvesta page.

The STAvesta/HUM is a system that enables TG-DSC measurements under controlled humidity conditions with water vapor.

This setup maintains a constant water vapor partial pressure (relative humidity) during measurement, allowing comprehensive evaluation of the thermal behavior of samples under various humidity environments. It is particularly effective for applications such as polymer hydrolysis, thermal behavior of hydrates in pharmaceuticals, and binder removal processes in ceramics.

Humidity control is achieved using a dedicated humidity generator (HUM-1), which produces humidified gas by mixing water vapor with nitrogen gas and supplies it to the STA system.

In addition, the dedicated furnace for water vapor atmospheres is equipped with a circulation unit to maintain a stable internal temperature, preventing condensation even under high humidity (up to 90%RH) and high temperature (up to 80°C) conditions.

A humidity sensor with feedback control ensures stable humidity conditions even during long-term measurements.

Relative humidity settings can be programmed into the temperature profile, allowing flexible control of humidity at each step of the heating program.

Like other STA models, the furnace unit is interchangeable with six different types of furnaces, offering wide applicability for various measurement needs.

STAvesta/HUM Features

STAvesta/HUM Specifications

| Model name | Thermo plus EVO3 STAvesta Humidity Controlled Simultaneous Thermal Analyzer |

|

|---|---|---|

| Technology | Thermogravimetry-Differential Scanning Calorimeter (TG-DSC) | |

| Measurement temperature range | Room temperature to 1,400°C | |

| Heating range (max) | 20°C/min | |

| Sample amount (max) | 1g (90 μL) | |

| TG range | ± 500 mg | |

| DSC range | ± 600 mW (100°C) ± 1,400 mW (1,000°C) ± 3,000 mW (1,500°C) |

|

| DTA range | ± 1,000 μV | |

| Relative humidity range | Room temperature to 80°C, 5 to 90%RH | |

| Wet gas flow rate | 200 to 500 mL/min | |

| Transfer tube temperature | Max 110°C | |

| Water-bath temperature | Room temperature to 90°C | |

| Dry gas flow rate | 0 to 500 mL/min | |

| Stability time | Within 10 min (10%RH) | |

| Continuous operation time | 60°C 90%RH, more than 100 hrs 80°C 90%RH, more than 40 hrs |

|

| Variable humidity system | Feedback type humidity control system | |

| Controlled humidity system | PID control | |

| Humidity stability | ± 2%RH | |

| Humidity sensor | Polymer type relative humidity sensor | |

| Measurement temperature element | Pt resistance | |

| Gas type | Dry N₂ gas | |

| Bubbler volume | 300 mL | |

| Measurement atmosphere | Inert gas (N₂), humidity atmosphere | |

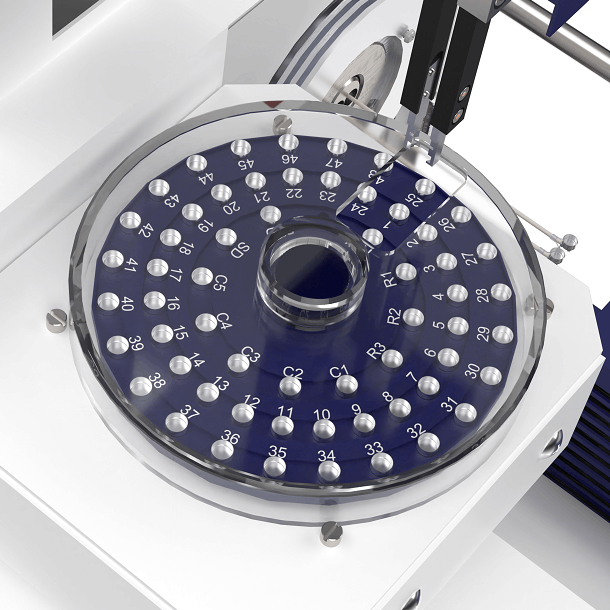

| Options | Automatic sample changer (Sample: 52, reference: 3, calibration sample: 5) | |

| Dimensions | STAvesta 412(W) x 355(H) x 621(D)(mm) 412(W) x 705(H) x 621(D)(mm) (with ASC) HUM-1 290(W) x 260(H) x 305(D)(mm) |

|

| Mass | STAvesta 50 kg 60 kg (with ASC), 66 kg (with ASC and safety cover) HUM-1 15 kg |

|

| Power requirements | STAvesta 1Ø, AC100-120 V/200-240 V, 50/60 Hz, 15 A HUM-1 1Ø, AC100 V, 50/60 Hz, 5 A |

|

STAvesta/HUM Options

The following accessories are available for this product:

ASC for STAvesta

Optional ASC (Auto Sample Changer) for greater throughput Upgradeable with ASC for automated measurements

Dynamic DSC (STA)

This method involves applying a sine-wave modulation to the traditional constant heating rate during measurements. By using this feature, specific heat measurements up to 1500°C can be easily conducted.

Sample Pan

Depending on the sample to be measured (especially if the sample is metal), it may melt the sample pan and damage the sample holder or other parts of the instrument.

Sample sealer / Sample crimper

A sample pan shaping tool with three functions: sample crimper, sample sealer, and high-pressure sample sealer.

Flow Meter

The flow meter controls the flow rate of the atmospheric gas (inert gas, air, etc.) supplied to the sample chamber.

Gas Selector

Links to the measurement program and switches the gases flowing into the sample chamber.

2ch-FLOW COMPO Jr.

Enables gas flow, flow rate setting and switching of gases with precision specified in the measurement program. Gas types and full scale can be selected.

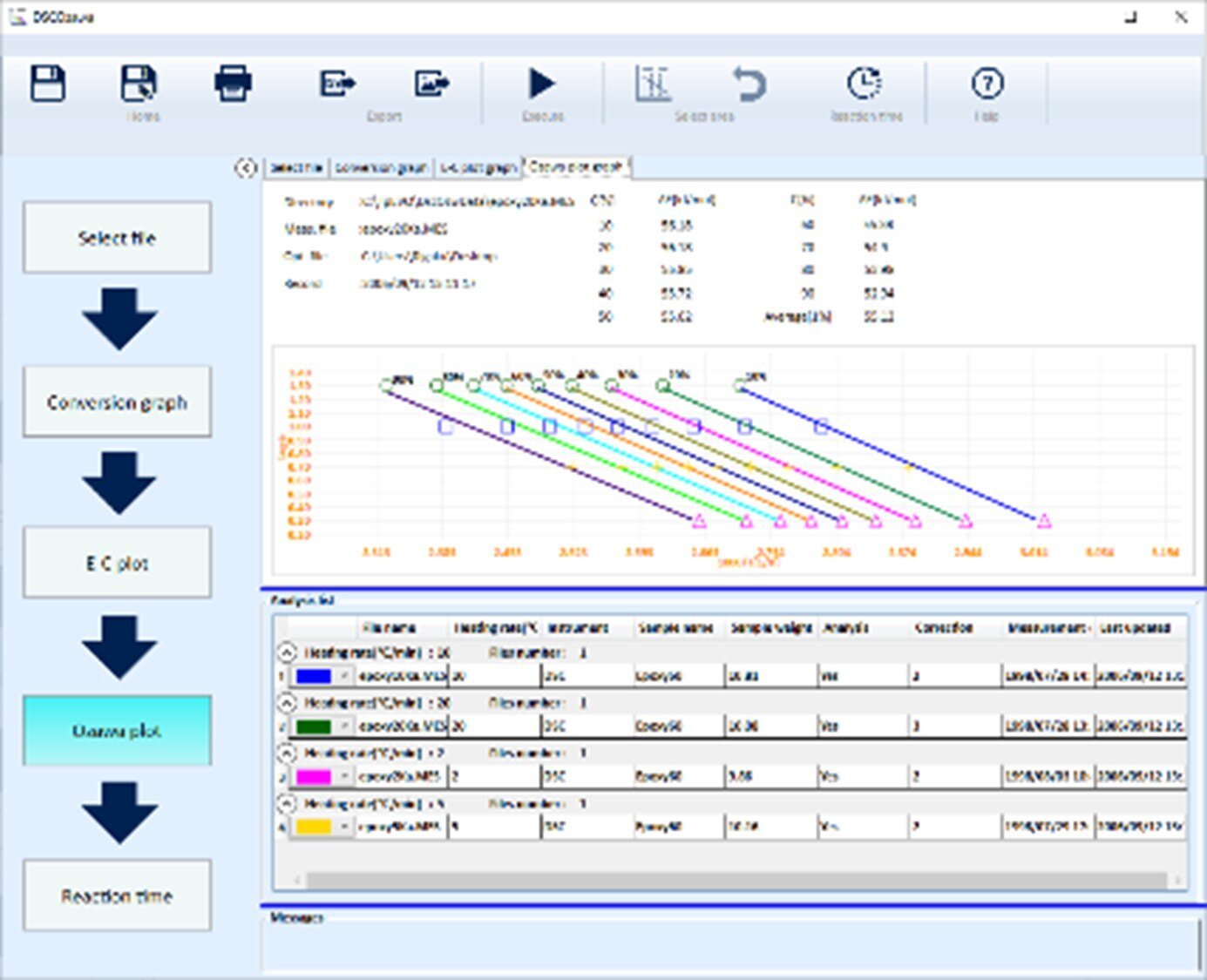

DSC Ozawa method/TG Ozawa method

In this method, the activation energy can be estimated from more than three measurements with different heating rates, estimating the time to reach a defined degree of conversion.

STAvesta/HUM Application Notes

The following application notes are relevant to this product

-

B-TA1003 - The Behavior of Water Absorption and Dehydration of Organic Materials

-

B-TA1027 - Water Absorption Behavior of Materials for Biomedical Application by HUM-TG

STAvesta/HUM

Contact Us

Whether you're interested in getting a quote, want a demo, need technical support, or simply have a question, we're here to help.

_ja.png)