Application Note XRT1539

Scope

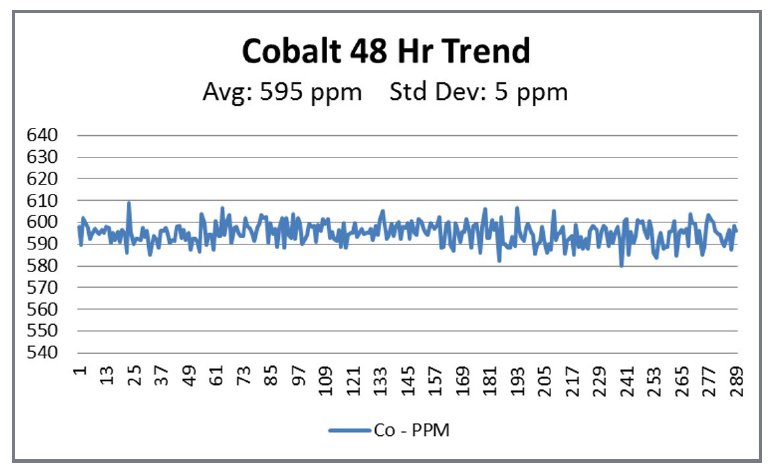

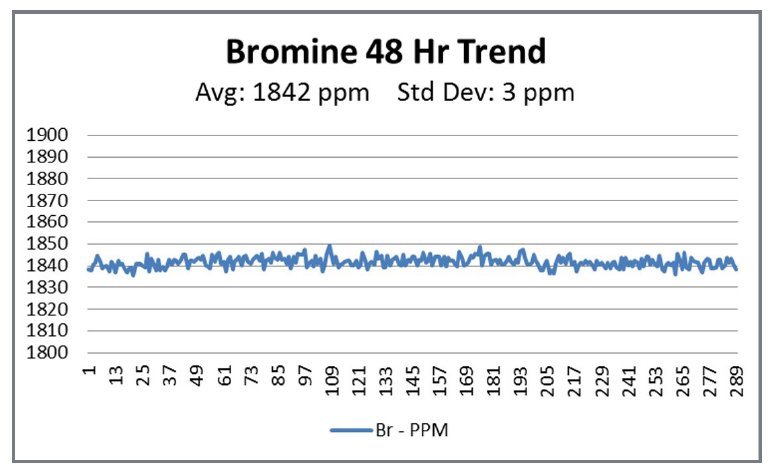

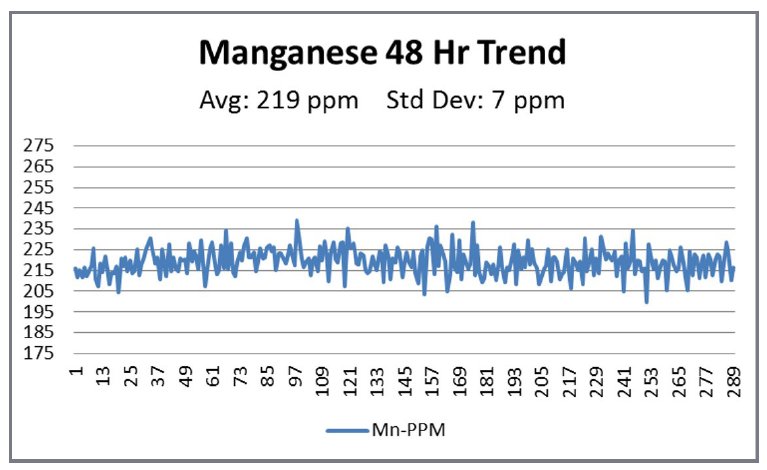

On-line measurement of cobalt (Co), bromine (Br), and manganese (Mn) in terephthalic acid (TPA) is demonstrated.

Background

Terephthalic acid (TPA) and purified terephthalic acid (PTA) are precursors in making polyester PET for polyester films, PET bottle resin, textile fabrics, and specialty chemicals. During production and use of TPA and PTA, the Co, Br, and Mn catalysts must be closely monitored to ensure optimum product quality. Since TPA and PTA are aggressive solutions, an on-line measurement is ideal. Continuous monitoring minimizes lab testing requirements, allows for process optimization, and is critical in ensuring the end product meets specifications. The Rigaku NEX OL offers simple and low maintenance on-line analytical technique for trending your process streams. Results are communicated to your plant DCS (distributed control system) via 4 – 20 mA current loops or MODBUS® over an Ethernet connection allowing for real-time, closed-loop control.

MODBUS is a registered trademark of Schneider Electric USA, Inc.

Calibration

An empirical calibration was built using a set of 8 standards. To demonstrate performance, water-based standards were introduced through the auxiliary sample input loop and analyzed in a static position.

| Component | Concentration range (ppm) |

| Co | 150-650 |

| Br | 360-1800 |

| Mn | 50-1000 |

Repeatability (Precision)

To demonstrate repeatability (precision), samples containing low and high amounts of Co, Br, and Mn were chosen from the set of calibration standards. Each sample was measured in a static position for ten repeat analyses.

Co Units: (ppm)

| Sample I.D. | Standard value | Average value | Std. dev | % Relative |

| 8 | 650 | 653 | 5 | 0.8 |

| 1 | 150 | 147 | 4 | 2.7 |

| 3 | 223 | 220 | 4 | 1.8 |

Br Units: (ppm)

| Sample I.D. | Standard value | Average value | Std. dev | % Relative |

| 8 | 1185 | 1181 | 5 | 0.4 |

| 1 | 966 | 962 | 4 | 0.4 |

| 3 | 362 | 365 | 2 | 0.6 |

Mn Units: (ppm)

| Sample I.D. | Standard value | Average value | Std. dev | % Relative |

| 8 | 999 | 994 | 9 | 0.9 |

| 1 | 50 | 46 | 5 | 10 |

| 3 | 864 | 869 | 8 | 0.9 |

NEX OL features and benefits

Real-time process control

Real-time process control- Trend analysis charting

- Capable of measuring elements Al to U, depending on application

- Robust Rigaku NEX QC+ optical kernel with SDD detector

- Industrial touchscreen user interface

- Unique toolless flow cell design

- No dangerous radioisotopes

Conclusion

The NEX OL offers real-time on-line trend analysis in a simple yet powerful and versatile system for quantifying the elemental composition of a process stream. The results of this study indicate that given stable samples, proper sample handling, and proper calibration technique, the Rigaku NEX OL EDXRF can achieve excellent results in monitoring the concentration of Co, Br, and Mn in TPA and PTA solutions.