Application Note B-XRI1035

Additive manufacturing enables the use of a wide range of materials, making it a key technology of interest for both industry and academia.

In research laboratories where novel processes are being developed, the flexibility of additive manufacturing opens exciting possibilities. However, this same flexibility introduces challenges in structural evaluation, requiring advanced characterization techniques.

X-ray computed tomography (CT) provides non-destructive three-dimensional (3D) insight into internal structures. This capability allows researchers to identify changes resulting from specific experimental parameters without risking sample damage, enabling direct and intuitive correlation of results.

About the sample: DLP ceramic samples

In this study, CT analysis was performed on cordierite ceramic samples at three processing stages:

- Green body (as manufactured)

- Brown body (baked up to 900°C)

- Sintered body (sintered up to 1450°C)

Digital Light Processing (DLP) was used to fabricate the ceramic samples, incorporating 2 wt% boron trioxide (B₂O₃) as a sintering aid to enhance densification and mechanical properties.

Manufacturing and processing were carried out by Prof. Jung-Ting Tsai’s research group at National Taiwan University of Science and Technology, Taipei, Taiwan. CT scans were conducted at Rigaku Americas as part of the study “Sintering behavior and mechanical properties of cordierite–boron trioxide ceramics via digital light processing” published in Ceramics International.

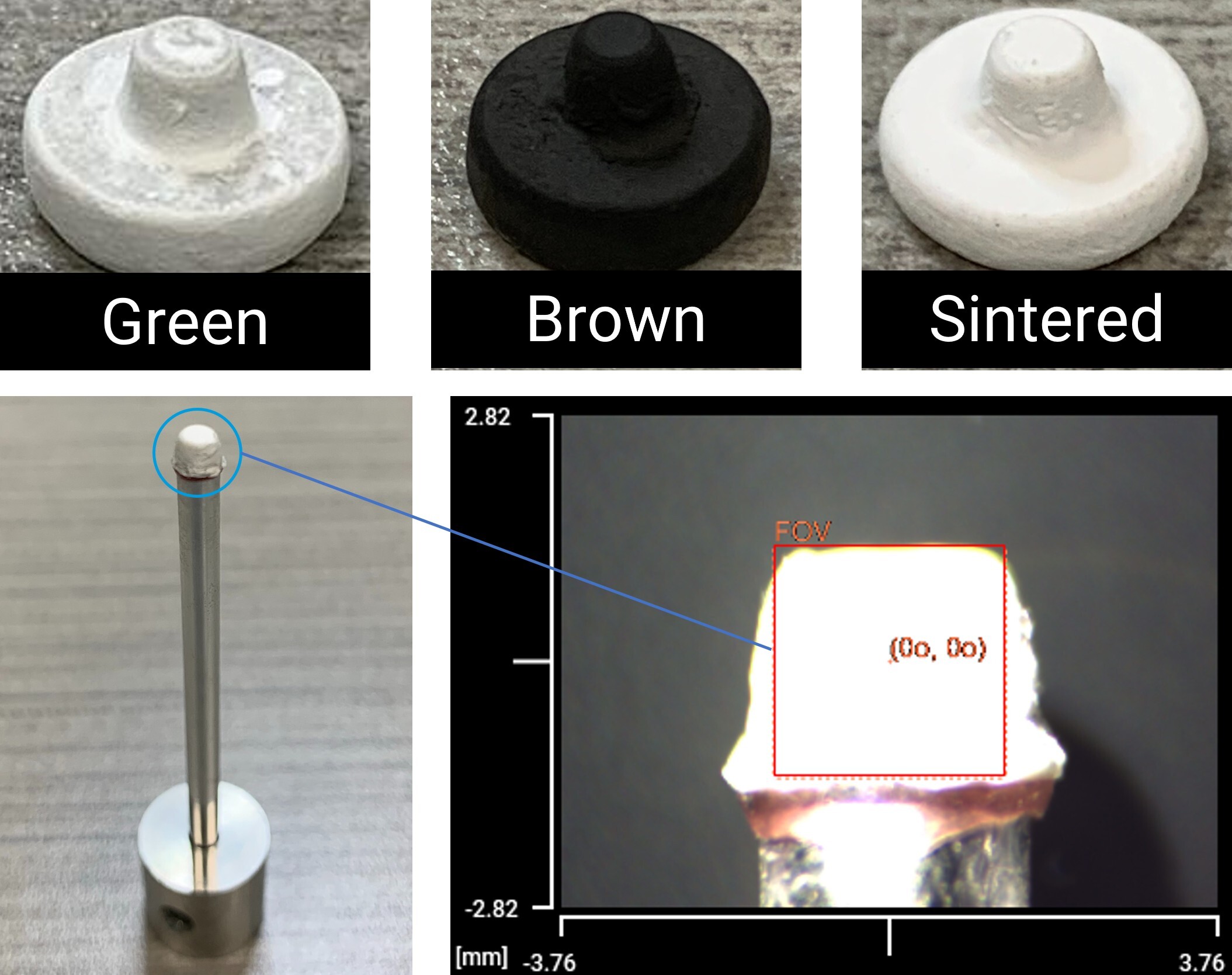

The figure below shows the Green, Brown, and Sintered ceramic samples, along with their CT mounting setup.

Analysis procedure

- All three samples were scanned using Rigaku nano3DX, a submicron-resolution CT system.

- 3D images were segmented via histogram thresholding to distinguish material from pores spaces.

- Internal pores were analyzed to study microstructural development across the three processing stages.

CT scan

Expected internal features—such as porosity and layer interfaces—range from tens to hundreds of micrometers. To resolve these details, submicron voxel resolution and a high-quality light source were required. Samples were scanned using the nano3DX system at 50 kV and 24 mA, with a rotating molybdenum target. The system’s high-flux, quasi-parallel X-ray beam minimizes blurring typical of cone-beam geometries, preserving fine internal details in the resulting images.

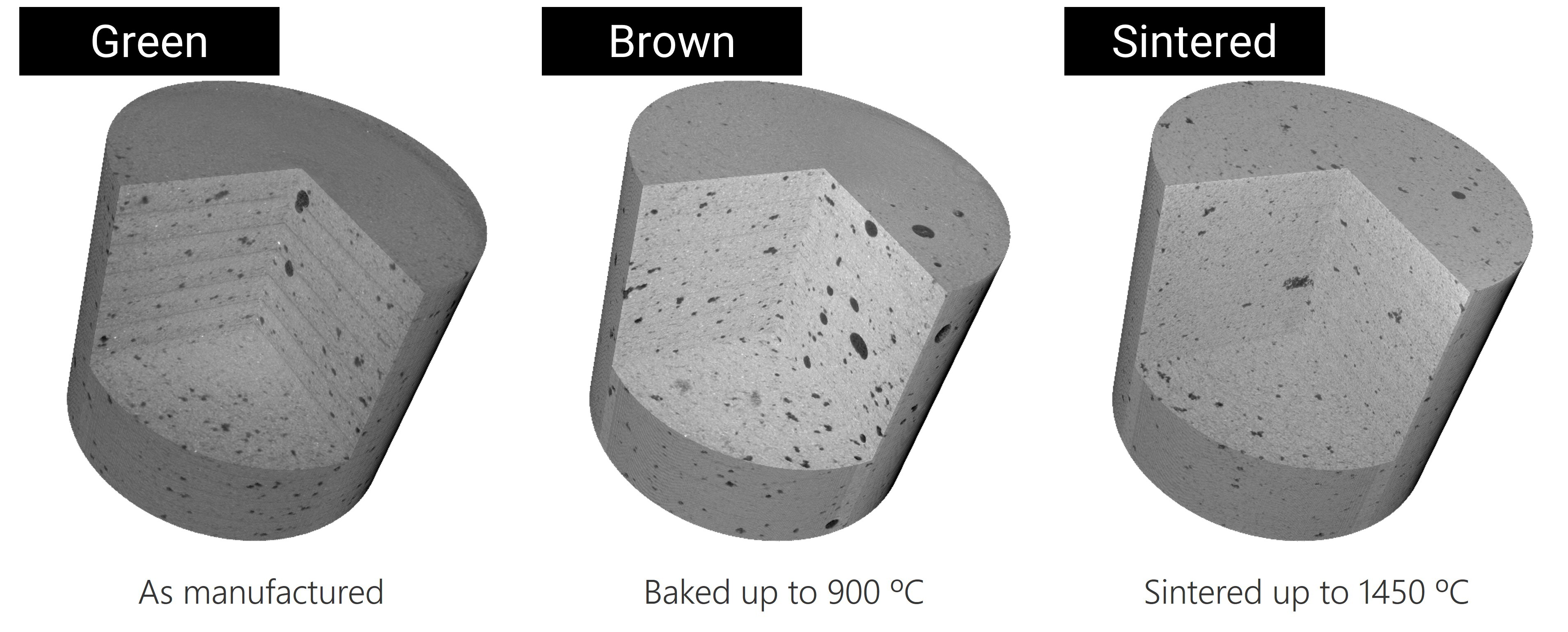

3D renderings of the Green, Brown, and Sintered ceramic samples are shown below.

Layered structure evolution

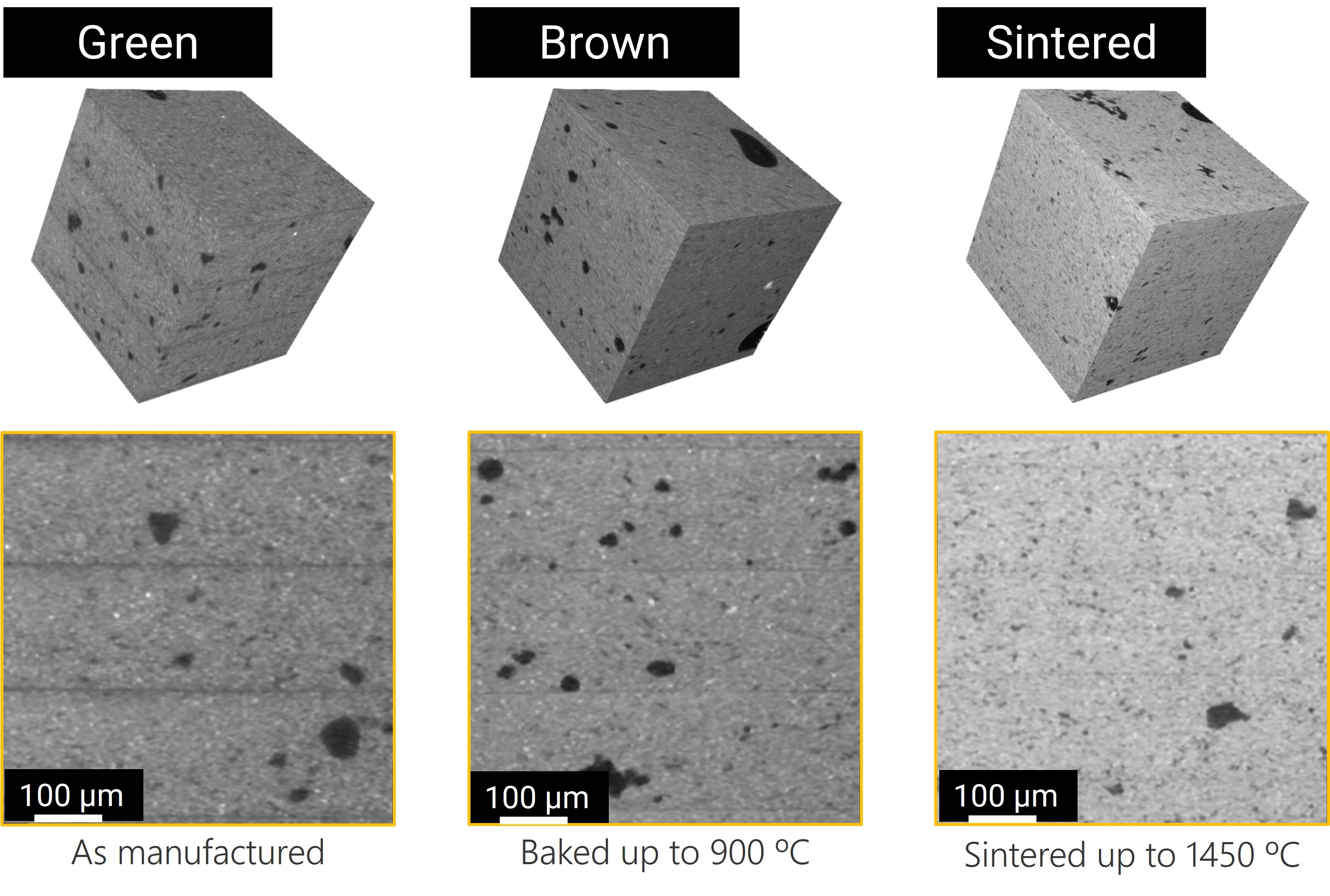

Small cubic regions were extracted from each sample for detailed inspection and feature analysis. Layer evolution is clearly visible in both 3D renderings and 2D cross-sectional views.

As processing progressed, the distinct layer boundaries became less pronounced due to material fusion during sintering. While qualitative inspection of grayscale images suggested structural densification, porosity differences were not immediately evident, necessitating quantitative pore analysis.

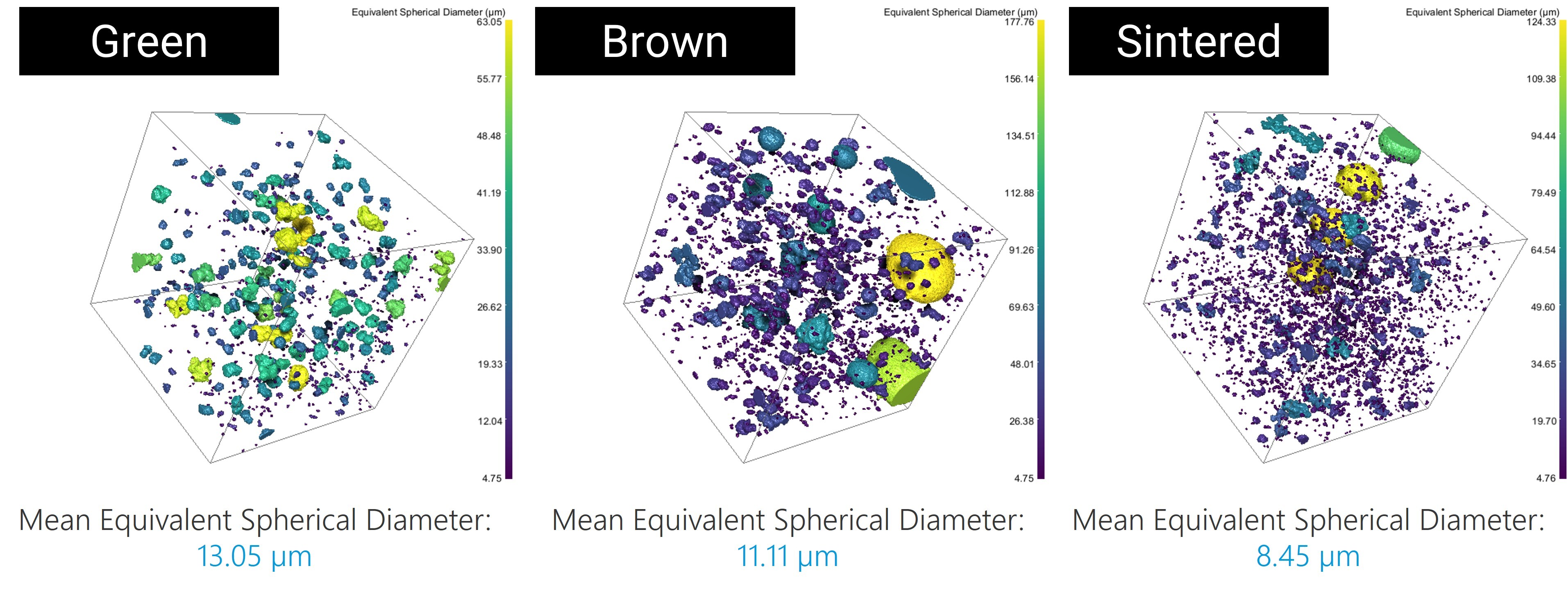

Pore analysis

Pore segmentation and visualization were performed using Dragonfly 3D World software. Results show that the total number of pores increased in both the Brown and Sintered samples compared to the Green sample. Quantitative analysis revealed that pore volume fraction rose from 1.55% (Green) to 4.46% (Brown) and 4.34% (Sintered).

Despite the overall increase in porosity, the average pore size decreased. The mean equivalent spherical diameter of pores dropped from 13.05 µm in the Green sample to 11.11 µm in the Brown and 8.45 µm in the Sintered sample. These results indicate dynamic structural transformations during heat treatment, where pores likely separated and coalesced under thermal and compositional changes.

Conclusions

This study demonstrates how high-resolution CT analysis provides valuable insight into the microstructural evolution of additively manufactured ceramics throughout thermal processing. The non-destructive 3D imaging approach reveals not only changes in pore quantity and size but also highlights the complex interplay between densification and layer fusion. Such comprehensive characterization is essential for optimizing sintering parameters and improving the mechanical performance of advanced ceramic materials produced via digital light processing.