Application Note B-XRI1033

About the sample: Respirator cartridge

Multi-gas respirator cartridges are essential components in reusable respirators, designed to protect users from a variety of airborne contaminants, including particulates, organic vapors, and corrosive gases. These cartridges typically consist of a durable plastic case equipped with flow baffles, which house both particulate filter media and a chemical-absorbing layer.

The efficacy of these cartridges relies heavily on the precise packing and distribution of the internal filter and adsorbent materials. Variations in these attributes can significantly affect performance, underscoring the importance of rigorous quality control measures throughout the manufacturing process.

X-ray Computed Tomography (CT) offers a robust, non-destructive method for inspecting the intricate internal components of respirator cartridges. This technology facilitates comprehensive assessments of the cartridge’s casing, flow baffles, filtration, and adsorbent media, while also identifying potential manufacturing inconsistencies. The ability to conduct such detailed analyses is crucial for both product development and compliance with stringent safety standards. In this application note, we image the full respirator cartridge and perform particle analysis.

Analysis procedure

- In this example, a respirator cartridge was scanned using a micro-CT scanner, the CT Lab HV. The first scan, a low-resolution image, provided an overview of the full cartridge, while the second scan, at a higher resolution, focused on an area of interest (ROI) containing the adsorbent media.

- The high-resolution image of the adsorbent media granules was segmented using deep learning to enable calculation of the particle and porosity volume phases.

- Watershed transformation was performed on the segmented granules to enable quantitative evaluation of granule size and shape distributions.

1. CT scan

A respirator cartridge was scanned and produced a comprehensive 3D image, capturing essential internal features such as the protective casing, filtration media, and packed adsorbent material. These features are critical for effective airflow management and ensuring optimal protection against airborne contaminants.

Figure 1: Video of 3D volume rendering of the full respirator cartridge

Figure 2: 2D cross-sections of the full cartridge displaying internal structure

Figure 2: 2D cross-sections of the full cartridge displaying internal structure

A second high-resolution scan allowed for a detailed examination of the adsorbent media, revealing well-resolved granules and variations in the grayscale values of these sorbent particles.

Figure 3: 2D cross-section highlighting the high-resolution granules

Figure 3: 2D cross-section highlighting the high-resolution granules

2. Image segmentation

The high-resolution scan of the adsorbent granules was segmented using deep learning . The analysis determined a porosity of 38.2%, with granules comprising 61.8% of the segmented volume.

Figure 4: Segmentation results and porosity analysis

Figure 4: Segmentation results and porosity analysis

3. Particle analysis

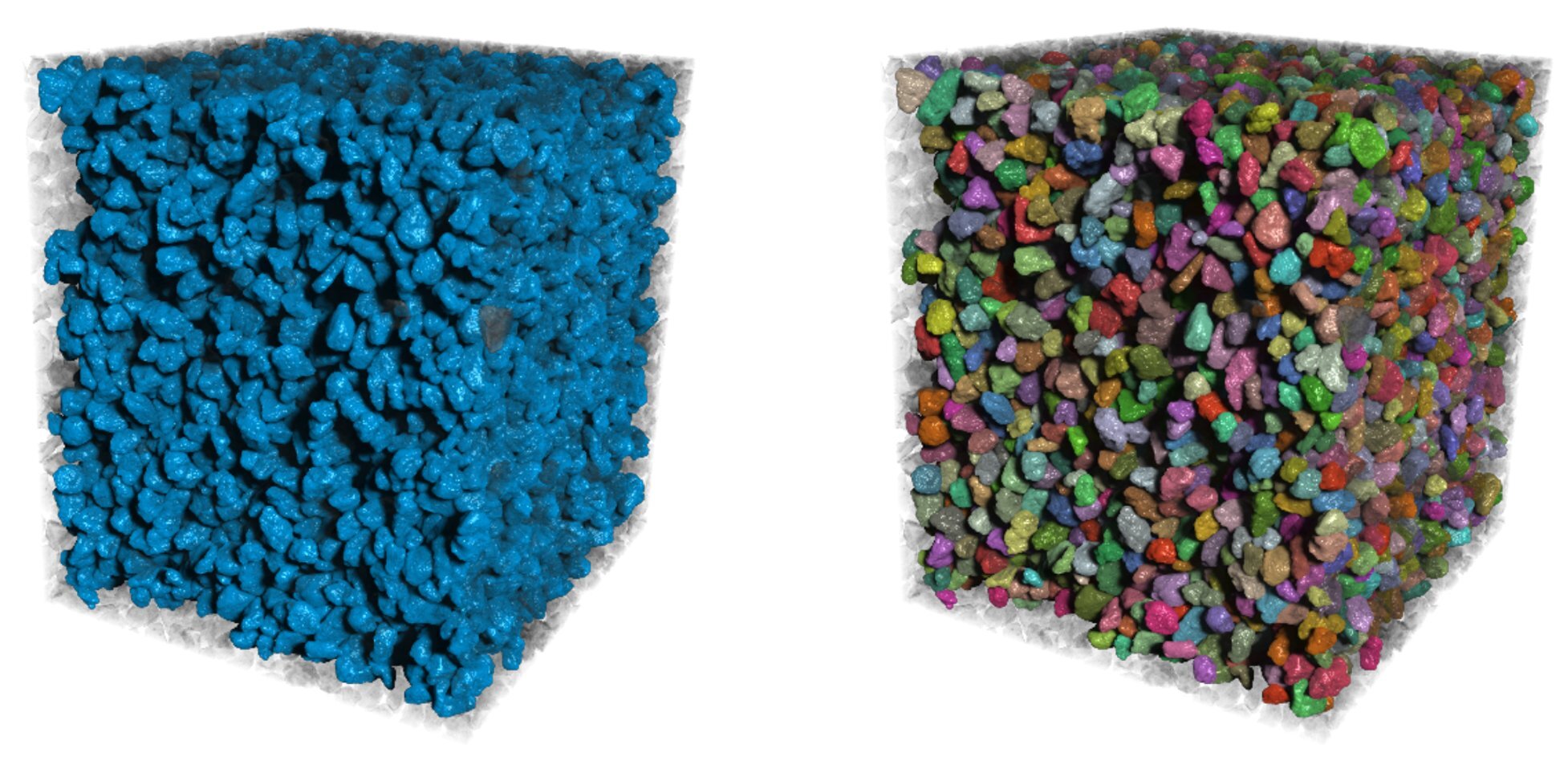

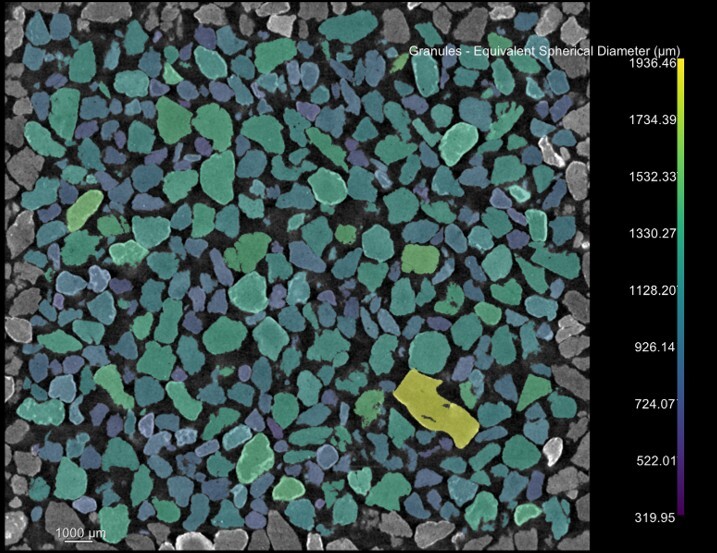

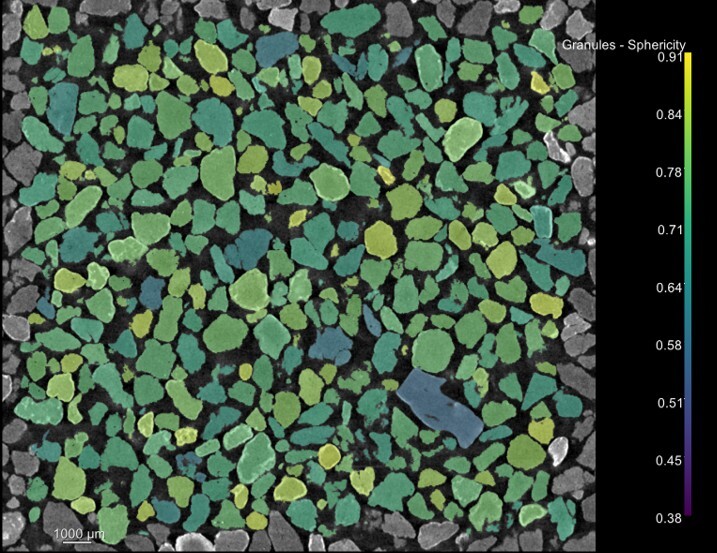

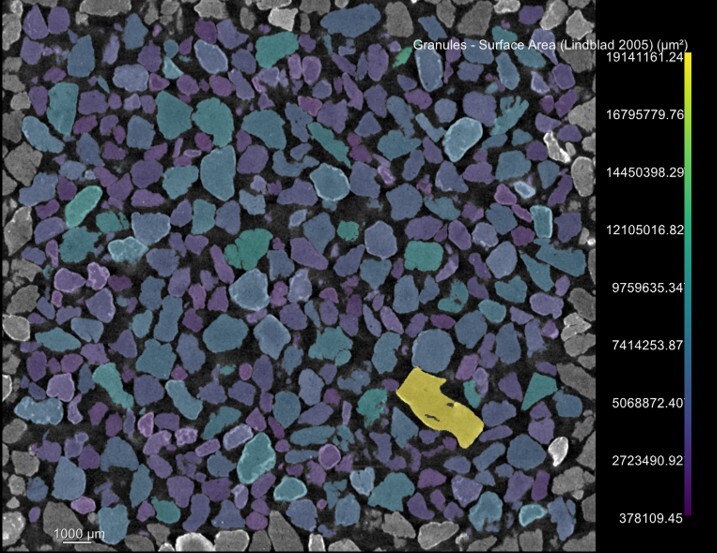

The adsorbent granules were separated using a watershed transformation. On-edge particles were filtered out to ensure that any calculations were performed for full versus partial granules. This allowed for a quantitative analysis of the particle size and shape distributions. A color-coded 3D map was generated to show variation among the sorbent granules.

Figure 5: 3D Segmentation and watershed results, excluding border granules

Figure 6: Particle analysis results color-coded by equivalent spherical diameter

Figure 7: Particle analysis results color-coded by sphericity

Figure 8: Particle analysis results color-coded by surface area

Conclusions

X-ray CT scans provided non-destructive 3D inspection method of the internal structure of a multi-gas respirator cartridge. Deep learning segmentation and watershed-based particle analysis enabled detailed characterization of the filter media. The results show how CT scans can support quality assurance, design optimization, and performance benchmarking in respirator cartridge development.